ProtoSoon is a China-based manufacturer offering on-demand services such as 3D printing, CNC machining, vacuum casting, and injection molding. With a focus on rapid prototyping and small to mid-scale production, ProtoSoon supports product developers and businesses with a broad range of manufacturing technologies and materials – all accessible through a streamlined online ordering system.

Table Of Contents

- About ProtoSoon

- 3D Printing Capabilities

- Supported Materials

- Online 3D Printing Quoting and Ordering System

- Full Manufacturing Services

- Industry Applications

- Trusted Worldwide

- Learn More (Video)

About ProtoSoon

Founded in 2014, ProtoSoon is a China-based digital manufacturing service provider delivering precision-made parts to clients in a variety of industries. Operating with over 120 pieces of equipment, the company offers support throughout the product development process—from early prototypes to production-ready components.

ProtoSoon’s comprehensive service offering includes metal and plastic 3D printing (SLA, SLS, SLM, MJF), high-accuracy CNC machining, low-volume vacuum casting, and scalable injection molding. The company stands out for its quick lead times, instant quoting system, and commitment to quality across industries such as aerospace, automotive, medical devices, and consumer electronics.

3D Printing Capabilities

ProtoSoon offers a wide range of industrial 3D printing technologies to meet diverse application needs across prototyping and functional part production.

For metal applications, ProtoSoon provides SLM, which builds fully dense metal components by fusing powdered metals layer by layer using a high-powered laser. This technology is well-suited for complex geometries and high-performance industrial parts.

For plastic applications. Among the available options is SLA, a resin-based process known for its high resolution and smooth surface finish, making it ideal for visual models and intricate designs. SLS, another popular method, uses powdered nylon materials to produce durable, end-use parts with excellent mechanical strength. MJF is available for fast, accurate production of strong, detailed nylon parts—particularly useful in low- to mid-volume production runs.

These technologies allow customers to choose the most appropriate method based on performance requirements, material properties, and project goals.

Supported Materials

Metals:

- 316L Stainless Steel, 17-4PH

- Maraging Steel, Titanium

- AlSi10Mg, Aluminum 6061

- Inconel 718/625

Image ProtoSoon

Plastics and Resins:

- Standard and Tough Resins, High-Detail Resin

- Transparent Resin, Somos® Series

- PA12, PA12+GF, PA6+GF, PA11

- TPU and more

Image ProtoSoon

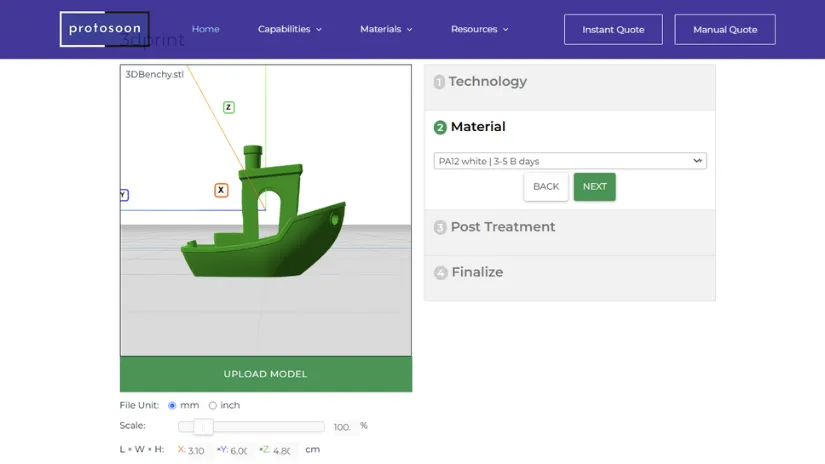

Online 3D Printing Quoting and Ordering System

To improve accessibility and efficiency, ProtoSoon launched its online 3D printing quoting and ordering system. With just a few clicks, users can:

- Upload their 3D files

- Select the preferred printing technology and material

- Instantly receive pricing

- Place orders directly online

We tested the system by uploading a Benchy model, and it returned multiple technology options, along with pricing estimates for each. The interface also allowed us to scale the model and choose post-processing options before finalizing the order, making the entire process smooth and intuitive.

Full Manufacturing Services

ProtoSoon’s expertise doesn’t stop at additive manufacturing. The company also delivers:

- CNC Machining for high-precision parts

- Vacuum Casting for small-batch production

- Injection Molding for scalable mass manufacturing

For those interested in exploring these technologies further, the ProtoSoon Blog features guides, examples, and tips to help you choose the right process for your needs.

Industry Applications

ProtoSoon supports a wide range of industries by delivering tailored manufacturing solutions that meet specific performance, regulatory, and design requirements.

In the aerospace sector, ProtoSoon helps produce lightweight, durable components suitable for both prototyping and end-use in aircraft and unmanned systems.

For the automotive industry, the company provides custom parts and functional prototypes used in everything from design validation to low-volume production.

In the medical device field, ProtoSoon offers high-precision manufacturing for components that demand accuracy and biocompatibility, supporting both R&D and functional testing.

For consumer electronics, ProtoSoon enables rapid iteration of enclosures, internal parts, and design mockups with a range of materials and finishes.

Industrial product developers rely on ProtoSoon to fabricate tooling, jigs, and complex mechanical parts that support ongoing innovation and operational efficiency.

Trusted Worldwide

With customers in over 80 countries, ProtoSoon is recognized for:

- Consistent product quality

- Reliable on-time delivery

- Excellent customer service

The company’s use of digital tools, combined with a customer-first mindset, makes it a standout choice for businesses looking for efficient, scalable, and transparent manufacturing solutions.

Learn More (Video)

For a visual overview of ProtoSoon’s services and facilities, watch their introduction video on YouTube. The video highlights key manufacturing capabilities, including 3D printing, CNC machining, and injection molding, while offering a behind-the-scenes look at their production environment and equipment in action. It’s a useful resource for anyone considering ProtoSoon as a partner for rapid prototyping or small-scale manufacturing projects.