Whether an STL file was created in design software or was it a result of a 3D scan, it may need repair. Even though slicer software for 3D printing is getting better and more intuitive, sometimes a file still needs fixing using other tools. Here we will list some software and online tools to deal with printability issues.

This Guide Covers

When STL Needs Repaire

There are many things that can be wrong with a model which may still look OK in a preview. This may cause issues when a slicer software tries to read the model file and to turn it into a G-code command for a 3D printer. The most common issues are: thin walls, holes in the meshes, no manifold meshes, separate surfaces and other.

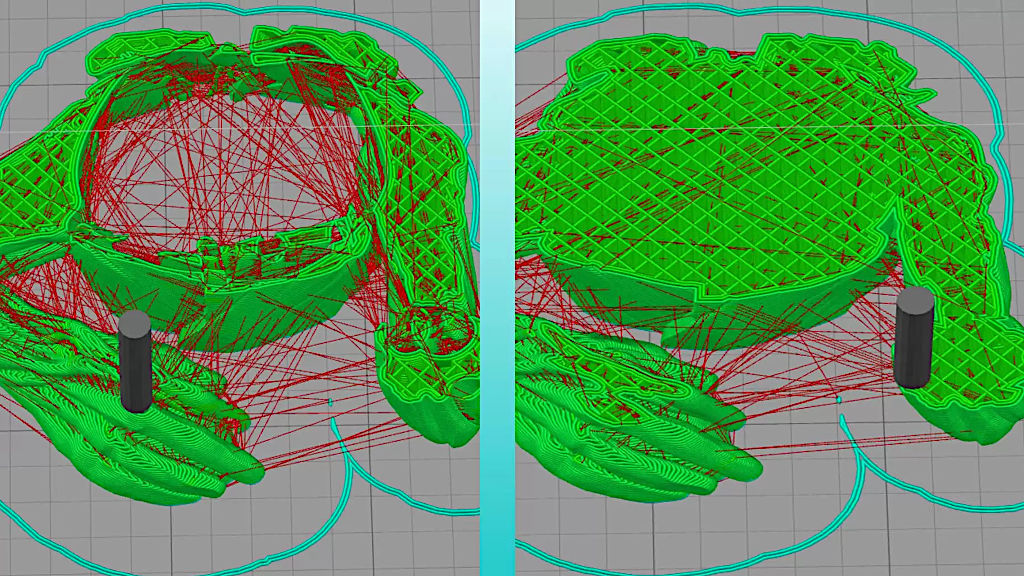

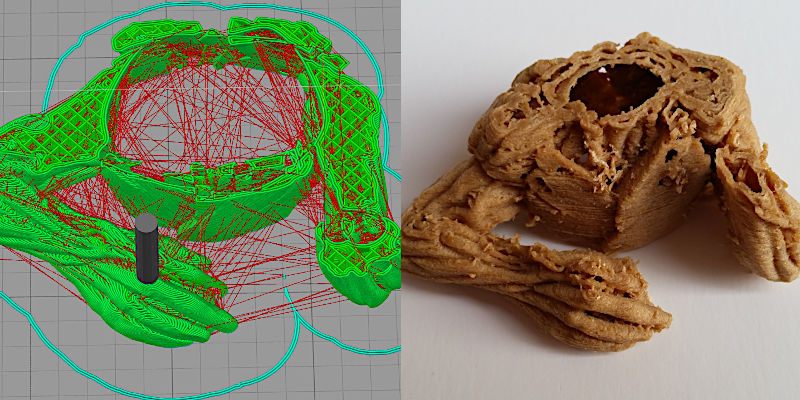

©3DWithUs – Image: Max Funkner

A brief example. Initially, I ignored all unnecessary retractions in the preview and tried to print this model in wood. And of course, I quickly learned that the wood composite material is tricky to deal with, and with a lot of retractions, it produced stringing, missing layers or a print failure. Even if this still could work using PLA or ABS, the repaired file was printed in wood without a problem on a budget FDM 3D printer.

©3DWithUs – Image: Max Funkner

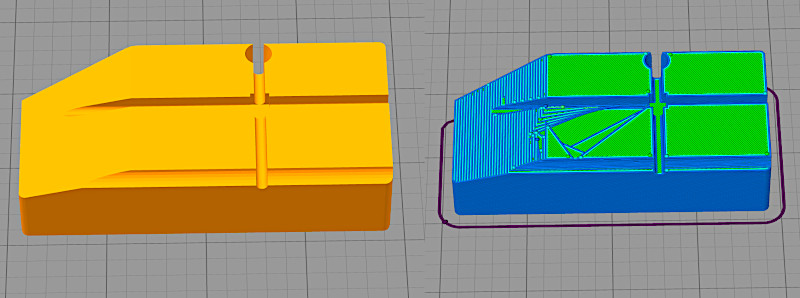

In the case of an iPhone dock for Volvo, I decided even not to start printing as there was a massive hole in a Gcode preview.

Slicer Software

Before trying online or offline STL repair tools, I would recommend trying other slicer software instead. My usual choice is PrusaSlicer, Cura, Simplify3D or ideaMaker, not in a particular order, usually depending on which 3D printer I use.

There is a lot of research work and coding ongoing to make slicer software perform better. Basically, these are the last-tier software that make our models printable. As these are getting more sophisticated, quite often the problem is being solved in a slicer.

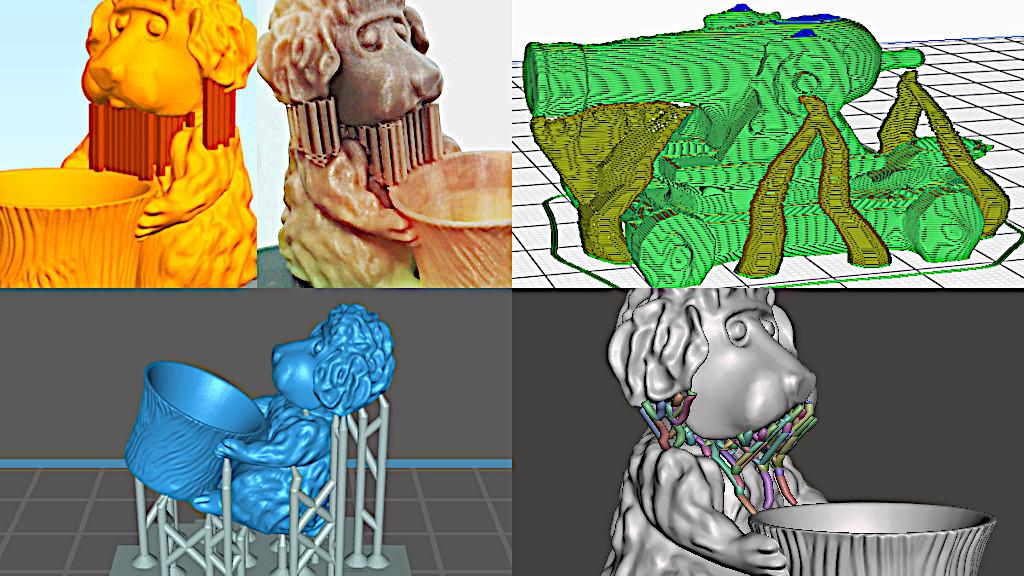

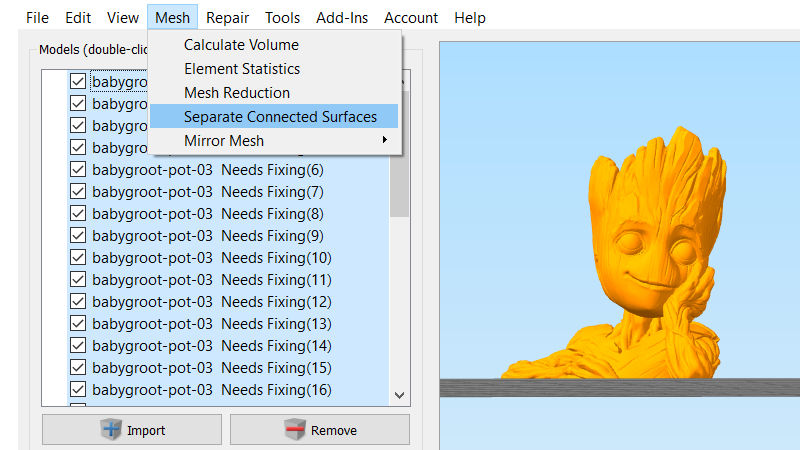

Simplify3D, for example, fixed two models that I wanted to print with Mesh – > Separate Connected Surfaces. Several years ago, I downloaded the popular models, Groot by Tom Davis and Julius Caesar by The MET, and found some issues. Simplify3D repaired them.

Screenshot: Simplify3D

When recently I placed the same faulty mesh models into PrusaSlicer and Cura, they fixed them instantly on upload. On the contrary, ideaMaker’s Auto Repair option couldn’t fix the problem. Therefore we can see that one slicer may succeed when others don’t.

Other Slicers with STL Repair Functionality

Links: ideaMaker, other.

Downloadable Repair and Design CAD Software

Design CAD software is where objects can be created and look all good in the preview but slicer software then has trouble slicing it properly.

Meshmixer

Price: Free

Link: Download

Meshmixer is a software that has a lot of powerful options with the printability of objects in mind. Quick fixing, patching, solidifying and even custom supports can be done there.

Blender

Price: Free

Link: Download

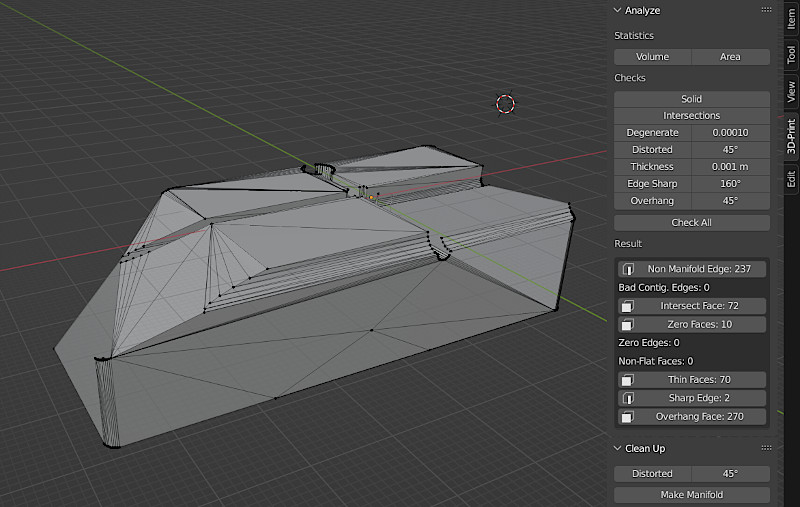

A sandbox, Blender has it all. Open-source community-driven software has many 3D printing-related add-ons. The 3D-Print add-on is one of the first that 3D print designers should be activating in the very beginning. With the Check All option, it is possible to see all 3D printability issues. This tool is for advanced users who want to find errors in their models. Make Manifold option may be a quick-fix solution, but it many cases, it just won’t work and there might be the need to fiddle with faces, edges, and vertexes.

Screenshot: Blender3D

The most popular CAD software, Blender, is FREE but has a medium-to-hard learning curve. If you are seriously considering learning 3D print design, I would recommend taking a Blender course by Jayson Wall on Udemy, here is the course review.

Microsoft 3D Builder

Price: Free

Link: Download

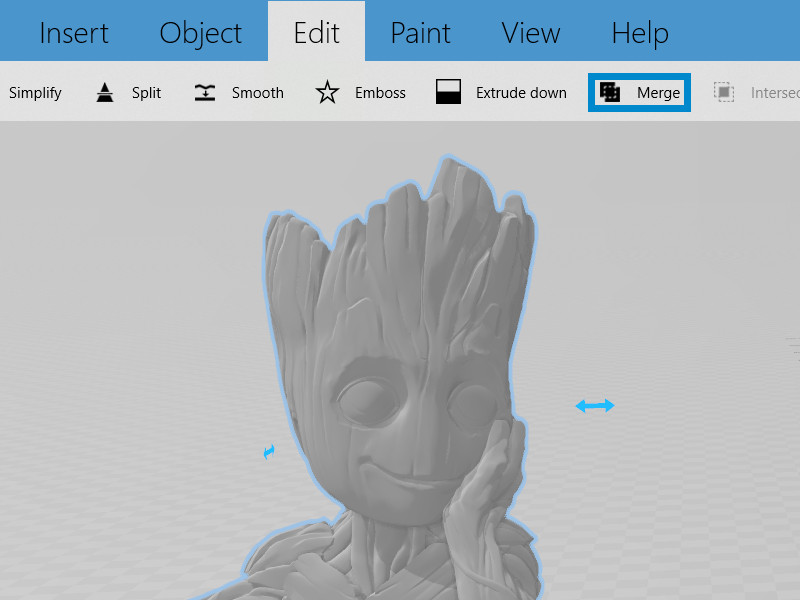

I personally haven’t been using 3D Builder often, but it gets highly praised on social media.

Screenshot: 3D Builder

Other Software with STL Repair Functionality

Links: Fusion 360 with Netfabb Premium, Meshlab, other.

Online Tools

In many cases, the most convenient would be to use STL repair online tools. The first thing we have to be aware of is that such tools can be limited in functionality, or come with expensive premium subscriptions.

Netfabb

Price: Free Trial/Premium Subscription

Link: Website

Netfabb Online Service. This is a service that was available online but now it is sold together with Autodesk Fusion 360. It can be tried for free as a trial but after that there is a very pricey subscription to have. Aimed at professionals in the industry.

NanoDLP

Price: Free

Link: Website

This is a new website that I found online. It didn’t fix any of my three models but I will keep the link here, just in case, if there is more development done to it.

MakePrintable

Price: Free/Premium

Link: Website

MakePrintable officially shut down its online repair services recently. On their website, you can find a message about it. Sad because they did a good job in the past helping me and others.

Quote: We’re proud of what we’ve accomplished. MakePrintable became the market’s most powerful cloud 3D printing file repair solution. MakePrintable has helped over 180,000 users to fix over 500,000 3D files.

Other Online STL Repair Tools

Links: coming soon …

Please let us know in the comment section below if you know another slicer software, offline or online, that comes with the mesh repair/auto-repair functionality.

Conclusion

As I already mentioned, slicer software is getting better and better, and if there is an issue, I would recommend just trying a different one. To have 2-3 slicer software on a PC is normal for even a casual 3D printer user. Online services, as we noticed, had a bumpy ride and either became redundant or were acquired. As for the CAD software, then the more experience users gain, the fewer issues will occur.