Acquiring a 3D printer is just the start of the journey. Even though the slicer software keeps becoming more user-friendlier from year to year, mastering how to use it on an advanced level, leads to unleashing the true potential of 3D printing. Let’s list what slicing software is there for resin and FDM machines, briefly mention their best features, and review some of them.

This Guide Covers:

- Slicer Software and Profiles

- The Best FDM Printer Slicer Software

- The Best Resin Printer Slicer Software

- Conclusion

– Open Source. Thanks to the open-source movement, such slicers benefit from new features very quickly, but at the same time, it is difficult for us to give credit to the developers. A lot of features were contributed via GitHub by its community and various manufacturers’ R&D teams.

What are Slicer Software and Profiles

A slicer, or slicing software, in 3D printing configures the files, commonly STL, to the format that 3D printers can read, G-Codes. This is done by setting a lot of parameters, such as the nozzle movement coordinates, temperature, speed, flow rate, etc. Plainly speaking, slicers tell 3D printers what to do.

There are slicers that help to make 3D printing experience beginner-friendly with some basic straight-to-action functionalities. When using such software for 3D printing a basic non-challenging model, an operator needs to do nothing apart from pressing the button to slice the model and save the file as G-code. But it will be a waste of an opportunity not to dig in further and not to learn more about the advanced settings or not to try some of the sophisticated features.

– Profiles. The popular slicer software usually has an ability to create profiles for the 3rd party 3D printers, even those not listed in the pre-set selection. There are two reasons why such custom profiles are in demand: 1) users get familiar with their favorite software and want to stay on it even with a different brand machine; 2) users want a feature that is not included with the software provided/recommended. Based on that, we would definitely recommend mastering a software that allows setting up the 3rd party printer profiles.

The Best FDM Printer Slicer Software

There are many free and paid software. While paid software, like Simplify3D, clearly dominated in the last decade thanks to its functionalities, stability, and quality, then today free software are equally good and enough for the majority of tasks.

PrusaSlicer by Prusa Research

Price: Free

Link: Download

A free, quick, and open-source PrusaSlicer keeps winning the hearts of the 3D printing community. In the past few years, this software has been regularly updated with the new features. If someone decides to test the limits of their machines, then PrusaSlicer is one of the first choices to go for.

On the download page, you can find a list of unique and new features. Among those are: Custom supports, MSLA/Resin, Multi-Material, Auto-updating profiles, Smooth variable layer height, Firmware flasher, Color change, Send G-code over the network, Paint-on seam, Built-in 3rd party profiles, Print time/feature analysis, etc. Here are some of the features in detail:

– Multi-Material. Not many 3D printer manufacturers tried such an ambitious project as multi-material 3D printing on FDM 3D printers. This is the slicer that prepares G-codes for the Original Prusa MMU (Multi Material Upgrade).

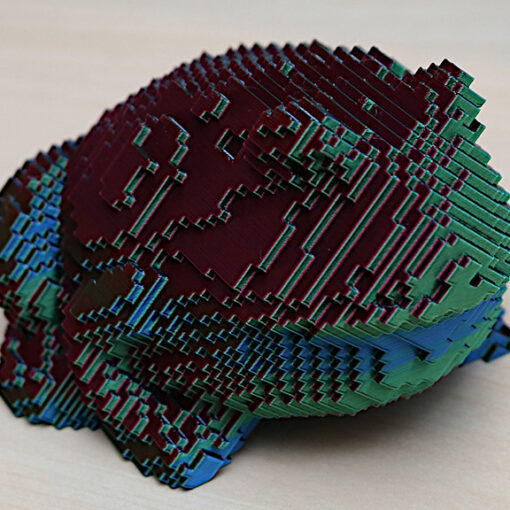

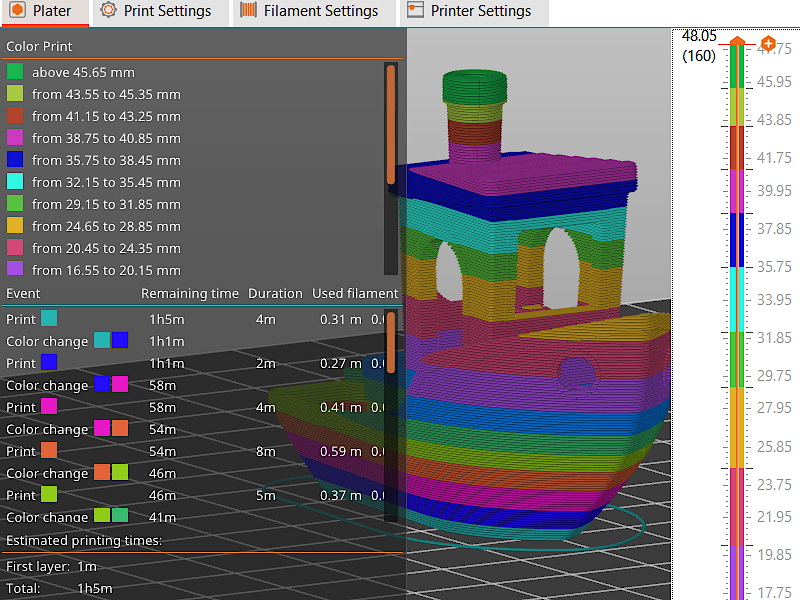

– Color Changing Feature. This is a feature that allows assigning a layer on which the machine will pause for the filament change. Initially, this feature was available via browser, but when PrusaSlicer became more advanced, the color-changing feature was made much clearer and user-friendlier. For example, it is possible to assign a color in the preview – this allows to check the result ahead of printing the model and helps to pick the right color. We printed some models and wrote about this technique in detail in our dedicated article.

Screenshot: PrusaSlicer

– 3rd Party Printer Profiles. When launching Configuration Wizard on PrusaSlicer, there is a list of Other Vendors where you can find such brands as Creality, Snapmaker, or Anycubic, for example. If the machine is not found, it is possible to build a Custom Printer profile.

Cura and Cura 5 by Ultimaker

Price: Free, Paid

Link: Download

Ultimaker’s Cura is the most popular slicer software. As it became available for free relatively early in the last decade, and it stayed to be the best free choice for a long time. Some 3D printer brand companies use the open source base to create their own, based on Cura, slicers, for example, Elegoo Cura. Other vendors ship their printers with the Cura profiles included on a USB or an SD cards.

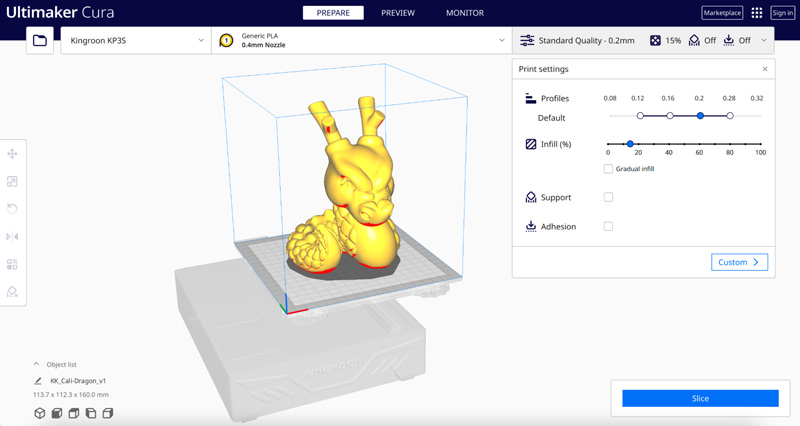

Screenshot: Ultimaker Cura

At the first glance, the software has a beginner-friendly user interface. All advanced settings are grouped in the additional tabs, and slicing the model looks very straightforward. Here are some new important features:

– Variable Line Width. The biggest feature that came with the recent Cura update. This feature makes printing thin lines better. The reduction of gaps and solid internal lines means the 3D print is stronger compared to the models printed after being sliced with earlier slicer versions.

– Preview. Cura has an impressive preview. Users can play the layer preview as a video to see exactly how the nozzle moves. A useful feature to have when checking the 3D printability of the models.

Elegoo Cura Preview – Strings Test File by 3DPrintBunny

MP4: Max Funkner

– Ultimaker Marketplace. This is where collaboration happens. Find slicer profiles and plugins that are rated by the community.

Simplify3D

Price: Paid

Link: Download

A few years ago Simplify3D had no competition in terms of functionality and features. A lag-less and crash-less software always loaded and worked quickly. Easy-to-operate custom support placement was a go-for feature, that saved not just material but time for post-processing and the quality of the objects. We would say it was the Best Slicer Software in the last decade.

An independent, in comparison to Prusa3D’s PrusaSlicer, Ultimaker’s Cura, or other free popular slicers, Simplify3D didn’t have many software updates. Nevertheless, some of the features stay strong in comparison to other software.

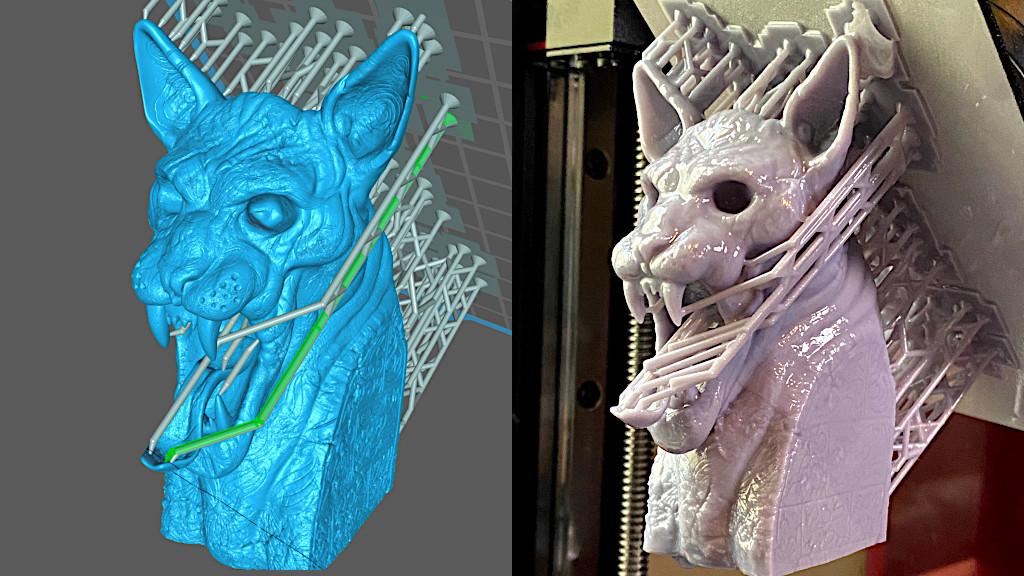

– Custom Support Placement. The award-winning feature was unbeatable for a long time. It allows custom support placement not just from the build plate but from the model itself. Also, it was possible to tune such supports so that the support structure marks on the print were minimal. This made the print post-processing much easier. We wrote about this feature in detail in our other article dedicated to support structures.

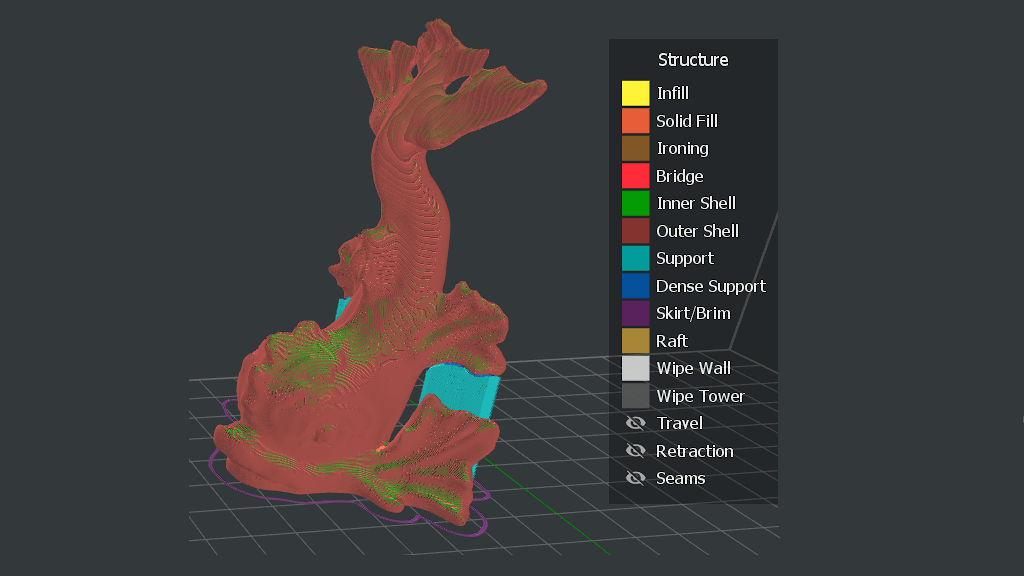

Screenshot: Simplify3D

©3DWithUs – Print and Photo: Max Funkner

– Preview. The simulation preview tool was also one of the first and strongest features compared to other slicers. Spending time looking at how the model will be sliced in such a preview was/is a key to a successful print.

– Speed and Stability. The fact is that Simplify3D kept processing of the complex and data-rich files relatively quick when other slicers kept crashing.

Other powerful features: Variable Print Settings, Multiple Extruders, Multi-Part Customization, Powerful Scripting Engine, Mesh Analysis and Repair, Machine Control and Monitoring, etc.

Raise3D’s ideaMaker

Price: Free

Link: Download

We recently found that ideaMaker by Raise3D had some impressive CAD-like features. Applying the custom texture or performing the basic Boolean operations are usually known as important tools for such software as Blender3D, Fusion 360, or Tinkercad. The quick basic modifications that allow easy editing and even remixing an object are very welcome.

– Profiles. There is a substantial online collection of other than Raise3D slicer profiles with user rating that can be found on their website. Such profiles are custom-made by users.

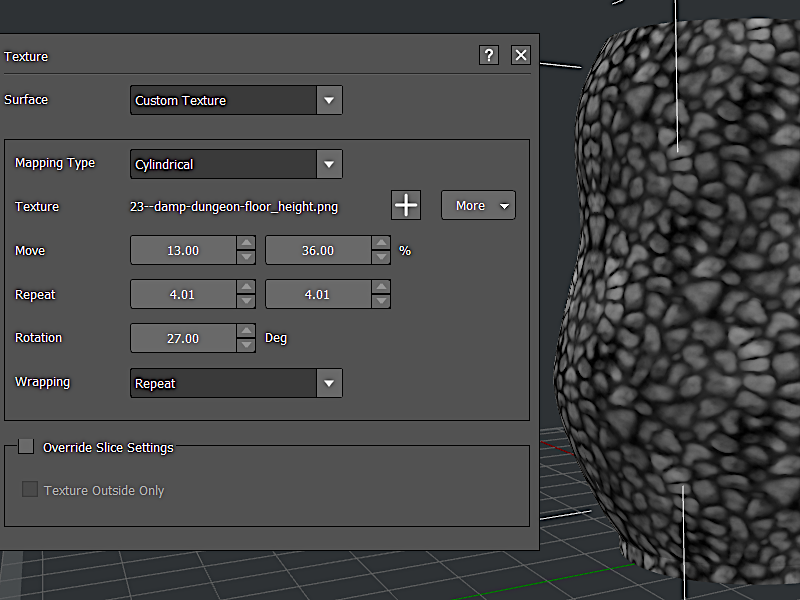

– Custom Texture. This feature is more of a CAD-like feature than of a typical slicing software. Texture works both on vases or other objects.

Screenshot: ideaMaker

– Boolean Operations. Another simple yet very helpful feature is Boolean operations. Instead of turning to CAD software, some simple operations can be done in the slicer instead. We find it very useful for customization or remixing of the existing models.

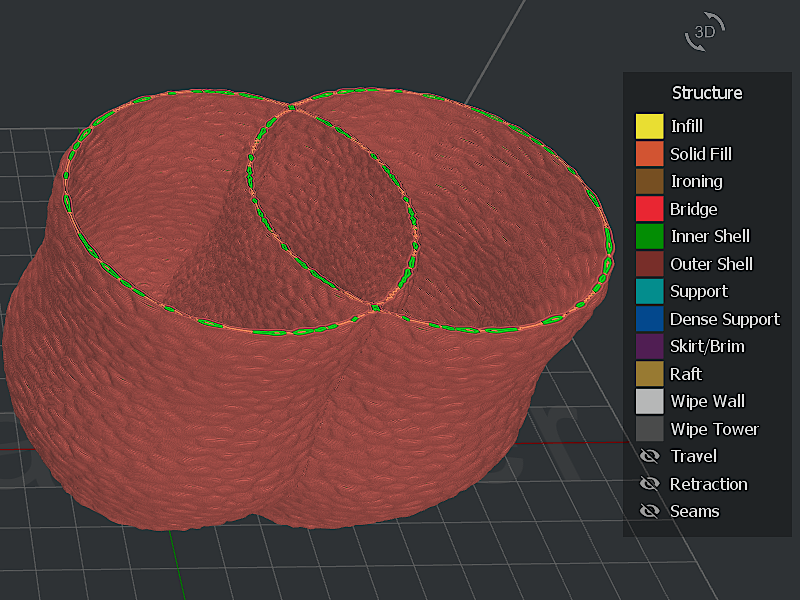

Sliced Preview in ideaMaker

Other powerful features: Customized Support, Automatic Parameters for Optimization, Variable Setting for Selected Region, etc.

Other Slicer Software

KISSlicer, Repetier, Slic3r, MakerBot Print, 3-in-1 Luban Review, etc.

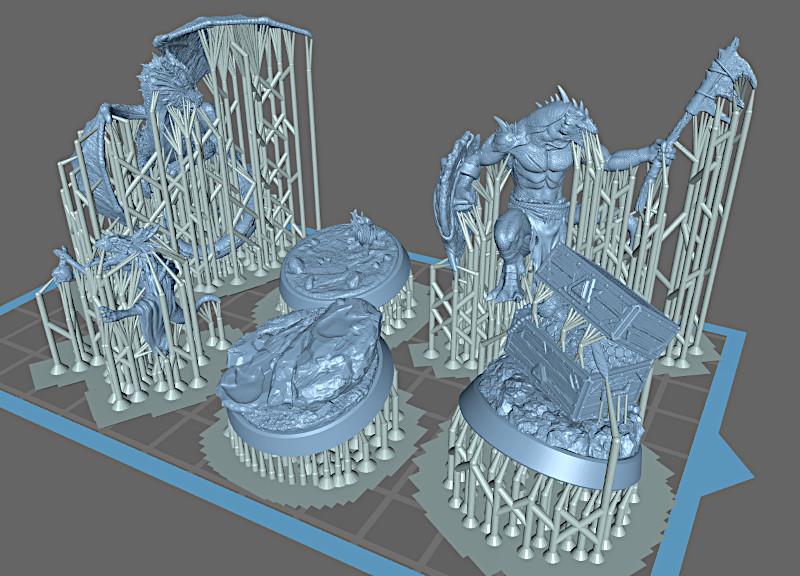

The Best Resin Printer Slicer Software

Compared to FDM, there are not many slicer software for resin 3D printers. Before the appearance of such software as Lychee or ChituBox, 3D printing community relied on such CAD software as Meshmixer to create custom supports, for example. It all changed at the end of the last decade.

ChituBox

Price: Free, Paid

Link: Download

Probably the most mentioned slicer software for resin 3D printing is Chitubox. We reviewed this software in full in this article. Such powerful brands in resin 3D printing, like Elegoo or Anycubic, have ChituBox as the recommended software.

Screenshot: ChituBox

Print and Photo: Andrew Sink

– Custom Support. As the support placement plays a much bigger role in resin 3D printing, this is where ChituBox has focused its attention.

Preview: ChituBox

– Hollowing. There are many reasons to hollow a model when printing with resin, and ChituBox makes the hollowing process a simple one-click operation that still offers a high level of customization.

– 3rd Party Printer Profiles. ChituBox is an independent software that offers powerful profiles for various brands of 3D printers.

Lychee

Price: Free, Paid

Link: Download

Another slicer software for resin 3D printers is Lychee by Mango3D. Lychee is based on a paid Mango software. Vibrant with rich colors, Lychee has the typical for resin printer slicers raft, hollowing, and automatic support options.

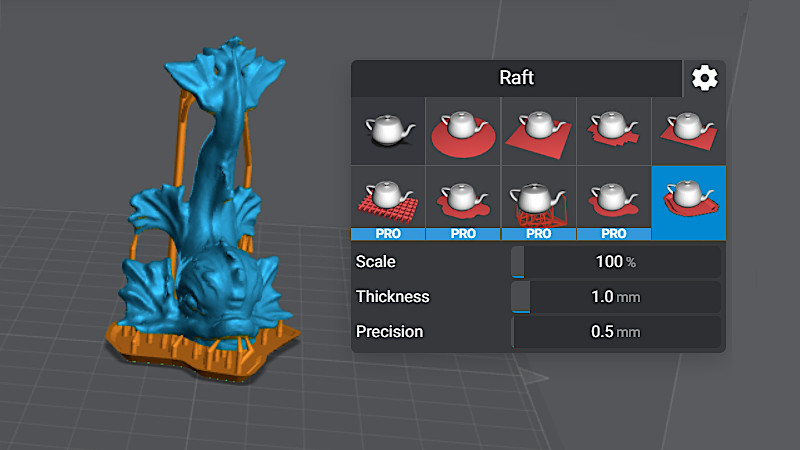

Screenshot: Lychee

– Supports Painting. Unfortunately, this is a PRO feature. Significantly speeds up the support placement.

Screenshot: Lychee

– Raft. The raft placement is straight forward with multiple free and paid options.

Other Slicer Software for Resin 3D Printers

PrusaSlicer, PreForm, Meshmixer, Anycubic’s Photon Workshop, Z-Suite, etc.

Conclusion

There are more than a dozen of free or paid software that can be considered as a slicer for 3D printing. It can be a slicer in a browser, or may be a part of a CAD. To test them all will take a lot of time and manpower. Eventually, we will expand this guide and add more as our expert reviewers keep testing various 3D printers with proprietary and open source software. Most of the slicers deserve the full-scale reviews as they are constantly upgraded and may have some unique features that make 3D printing better.

Read More: Support Settings in 3D Printing – Custom or Tree, Blocker or Enforcer?

An object with overhangs over 45 degrees normally requires supports to be added before 3D printing. Choosing the right support settings and structures is a skill that needs to be learned when using desktop SLA and FDM 3D printers. In this post, we will look at a few examples for comparison and give you some ideas.