Snapmaker’s U1 campaign has already made history, raising over $20.6 million from 20,680 backers and becoming the most funded 3D printer project to date. The U1 introduces a new approach to desktop 3D printing—combining high-speed performance, intelligent control, and a precision toolchanging system designed for efficient multimaterial printing. With a strong focus on clean color transitions and reduced filament waste, the U1 positions itself as a bold leap toward more accessible and advanced desktop fabrication.

Table of Contents (Jump to a Section)

- About Snapmaker

- Features and Specifications

- Image Gallery – Print Comparison

- What’s Next

- Manufacturing & Review Videos

- Conclusion

Where to Buy the Snapmaker U1

Price: From $849

Snapmaker U1 (September 2025): 20,680 backers pledged $20,614,548

Snapmaker 2.0 (May 2019): 7,388 backers pledged $7,850,866

Snapmaker Original (March 2017): 5,050 backers pledged $2,277,182

About Snapmaker

Snapmaker first rose to global prominence through two record-breaking Kickstarter campaigns, launching all-metal, multi-discipline 3-in-1 machines that combined 3D printing, laser engraving and cutting, and CNC carving. These became some of the most successful technology Kickstarters of all time.

With the Snapmaker U1, the company is returning to its roots — not just to launch a new product, but to reconnect with the community that helped build its legacy.

Kickstarter is where Snapmaker started, and our backers have always been a vital part of our journey,” said Daniel Chen, Snapmaker CEO. “With U1, we’re going back to our roots — combining what we’ve learned with what our community dreams of.

Snapmaker is empowering creators worldwide with high-quality desktop fabrication tools, best known for its all-in-one machines that support prototyping, education, and artistic expression — all driven by its mission to ‘Make Something Wonderful.’

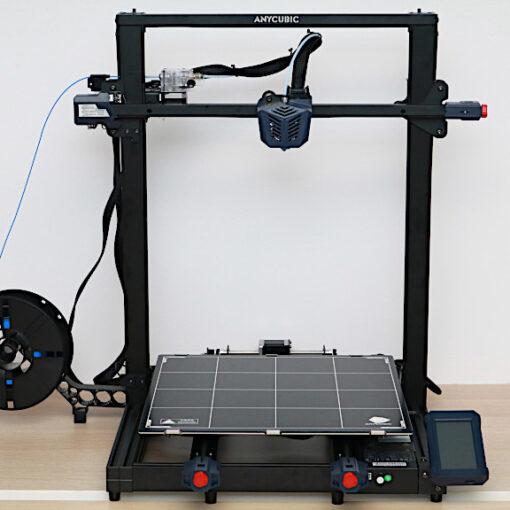

Snapmaker U1 Features and Specifications

While full specifications will be released on the day of the Kickstarter launch, Snapmaker has already revealed some standout features that highlight the U1’s potential for high-performance, multimaterial 3D printing in a compact desktop form.

- CoreXY Motion System: Designed for fast and stable movement, paired with a fully enclosed chamber ideal for temperature-sensitive materials.

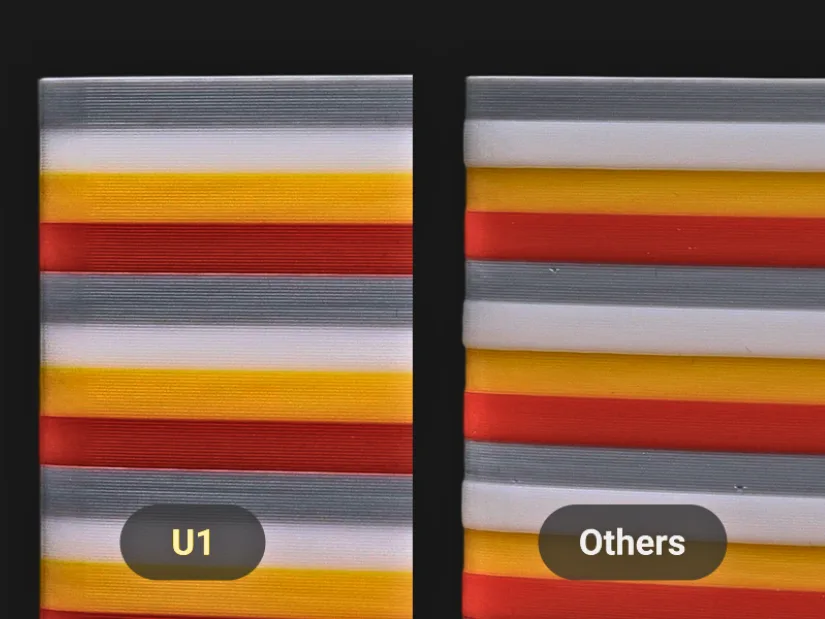

- SnapSwap™ Toolchanging: An intelligent automatic toolchanging system that reduces filament waste by up to 80% by eliminating the need for constant purging during material swaps.

Specifications:

| Feature | Specification |

|---|---|

| Printing Technology | Fused Deposition Modeling (FDM) |

| Build Volume | 270mm × 270mm × 270mm |

| Max Toolhead Speed | 500 mm/s |

| Max Acceleration Speed | 20,000 mm/s² |

| Toolheads Included | 4 |

| Max Flow for Hot End | 32 mm³/s |

| Nozzle | Stainless Steel (more options in testing) |

| Max Nozzle Temperature | 300°C |

| Nozzle Diameter | 0.4 mm |

| Filament Diameter | 1.75 mm |

| Part Cooling | Main & Auxiliary Part Cooling Fans |

| Build Plate | PEI |

| Max Heated Bed Temperature | 100°C |

| Basic Material Compatibility | PLA, PETG, TPU, PVA |

| With Optional Seal Cover (Coming Soon) | PET, ABS, ASA |

| With Seal Cover & Hardened Steel Nozzle (Coming Soon) | PC, PA, PA-CF, PA-GF (more options in testing) |

Find the full list of specifications at the end of the page on the Official Website.

Four Toolheads Work as One

Rather than swapping the entire toolhead, Snapmaker U1 uses its intelligent SnapSwap™ system to switch out key tool components — such as hotends or extruders — while keeping the main head in place. This allows up to four materials or colors to be used in a single print, with sharp transitions and minimal purging, all within a tightly integrated and efficient design.

Snapmaker confirms that the U1 is in the final stages of production, with rigorous quality control underway. As the launch approaches, more technical details and real-world demonstrations will be shared to give the maker community a closer look at this ambitious release.

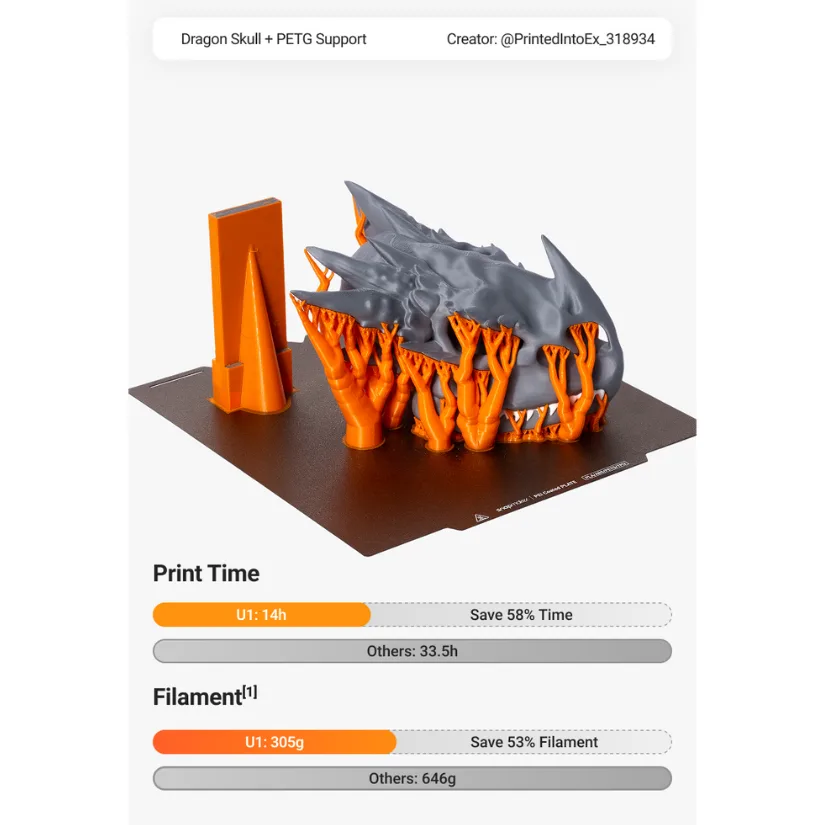

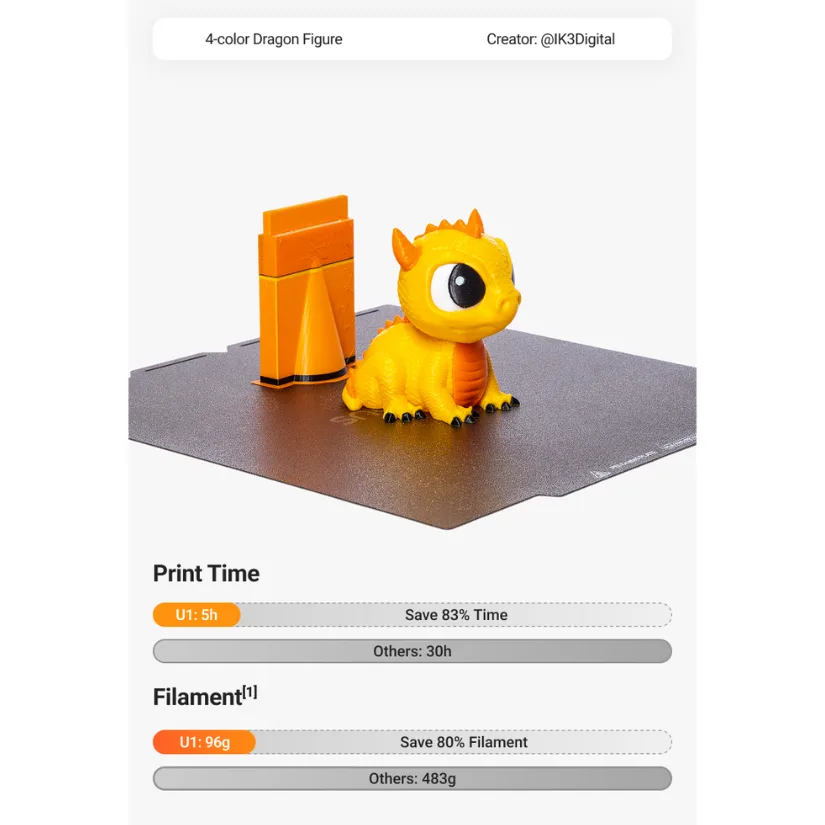

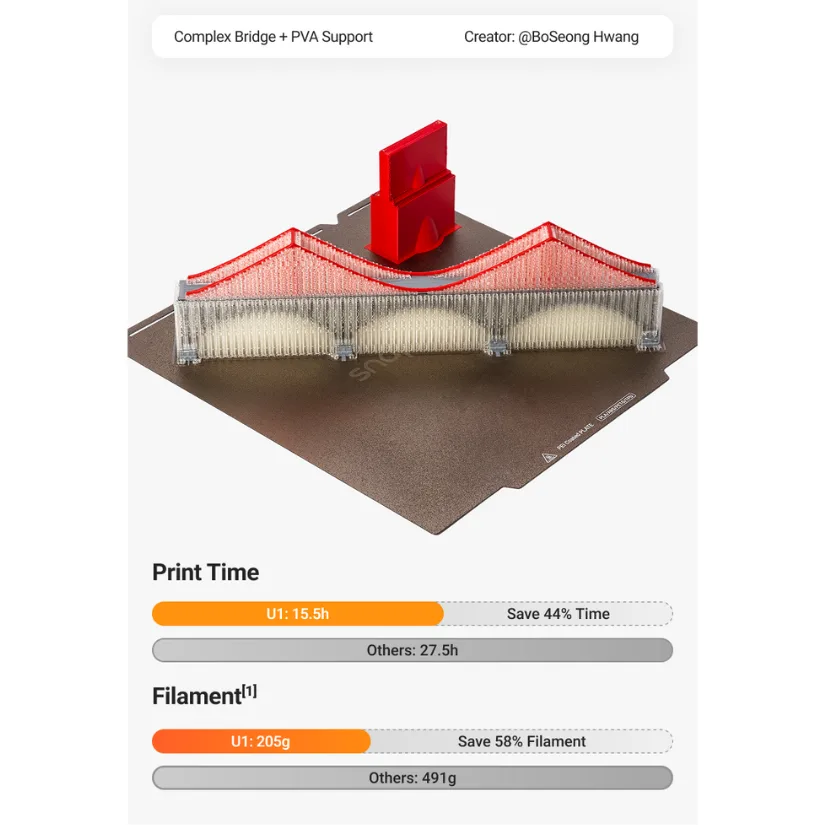

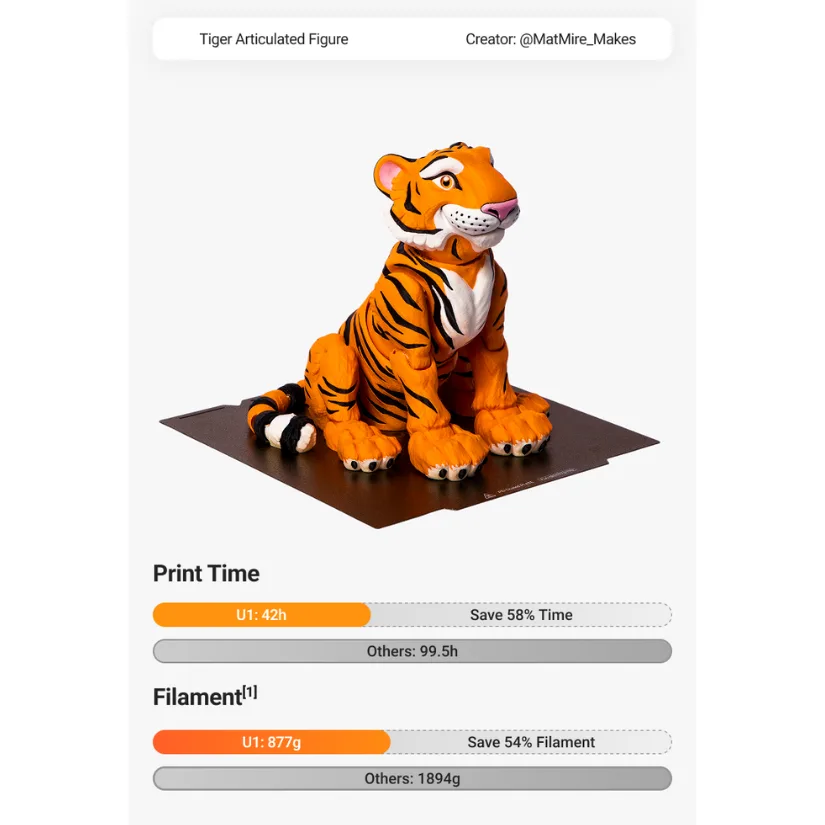

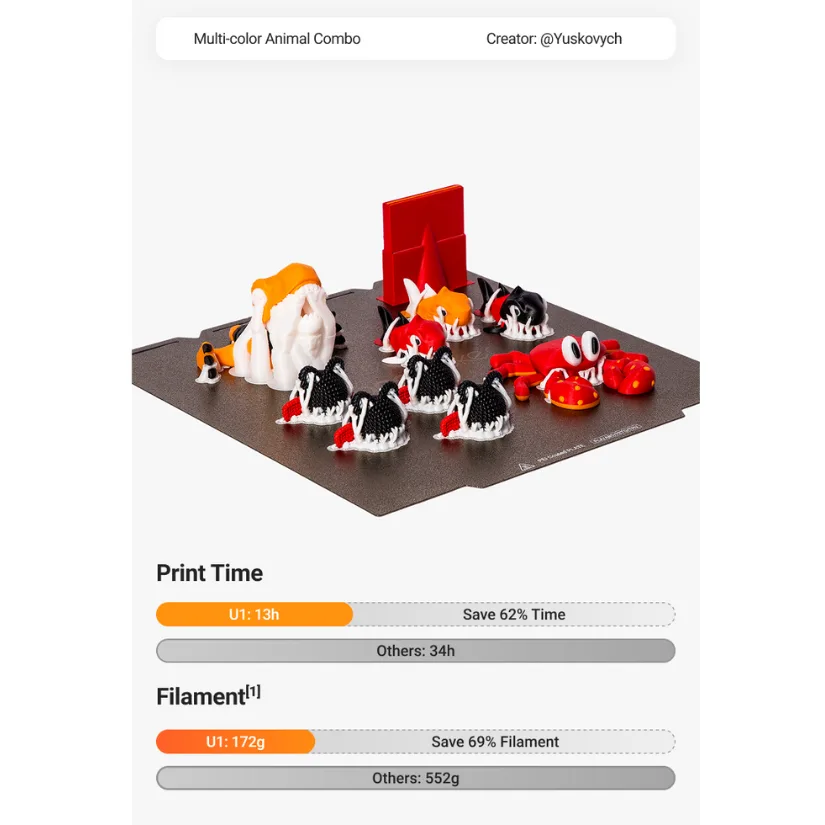

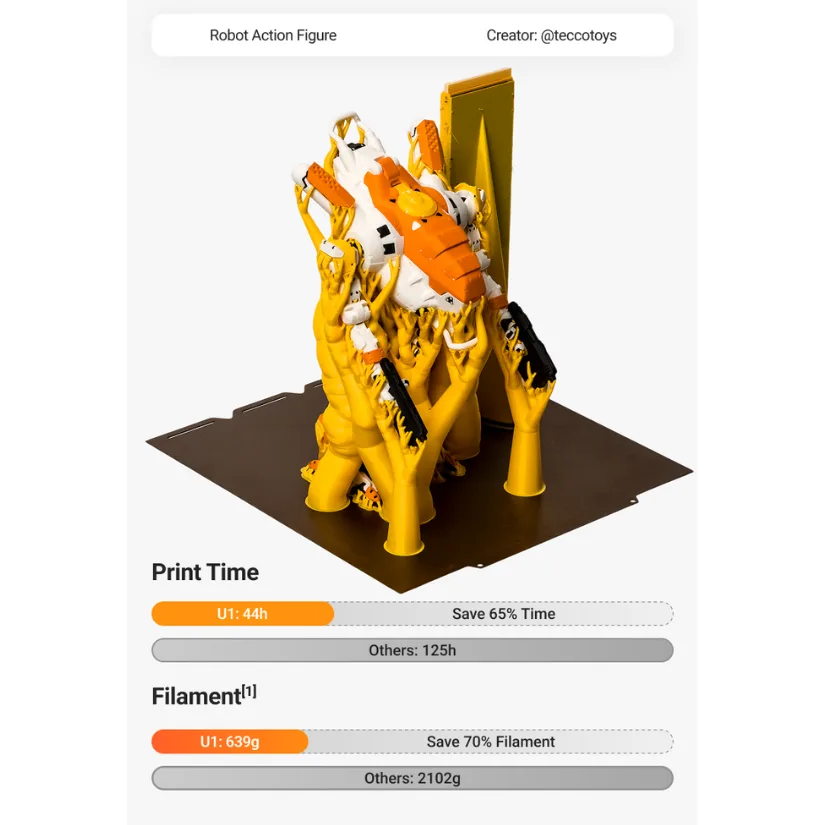

Image Gallery

Below are official and exclusive images of the Snapmaker U1 in action. Each test print highlights a specific use case, ranging from small to complex models and covering a variety of material types. Detailed comparisons highlight the printer’s efficiency in terms of time and filament savings. More images of test prints will be added following our hands-on testing.

(Designer: @PrintedIntoEx_318934)

(Designer: @IK3Digital)

(Designer: @BoSeong Hwang)

(Designer: @MatMire_Makes)

(Designer: @Yuskovych)

(Designer: @teccotoys)

What’s Next

We’ll be thoroughly testing the Snapmaker U1, focusing on print quality, toolchanging accuracy, and material handling. Stay tuned for our full setup guide, slicer tips, and hands-on print results. Join the discussion on our forum or leave a comment below.

At 3DWithUs, we’ve previously tested and featured Snapmaker’s recent products, including the Snapmaker Artisan and Snapmaker Filament Dryer. We’re excited to add the U1 to our lineup and share our findings with the community soon.

Review

Here is a review from beta tester The Real Sam Prentice.

Another video that cought our eyes is the manufacturing process. Spolier: a lot of robots.

Conclusion

Snapmaker U1 is off to a remarkable start and the excitement is well earned. With real toolchanging, cleaner multicolor prints, and a proven campaign, it’s one to watch. We’ll be sharing more hands-on results and impressions soon, so stay tuned.

Will be looking forward for updates. Price isn’t that much of a concern, but build volume is. Personally want a minimum of 300mm cubed though added Z axis over that would be beneficial.