In the ever-evolving world of 3D printing, precision and efficiency are paramount. One of the pivotal technologies driving this innovation is the servo drive. By enhancing control over the printing process, servo drives significantly elevate the performance and output quality of 3D printers. This guide will delve into the intricacies of servo drives, their working principles, advantages, and how they distinguish themselves from traditional stepper motors.

This Guide Covers

- What are Servo Drives?

- How do Servo Drives Work?

- Advantages

- Key Components

- Improve Print Quality

- Servo Motors vs Stepper Motors

- Right Servo Drive for Your 3D Printer

- How to Install and Calibrate

- Common Issues / Maintenance

- Applications

- Future Trends

- Conclusion

A servo drive is an electronic amplifier used to power electric servomechanisms. A servo drive monitors the feedback signal from the servomechanism and continually adjusts for deviation from expected behavior. Source: Wikipedia

What are Servo Drives?

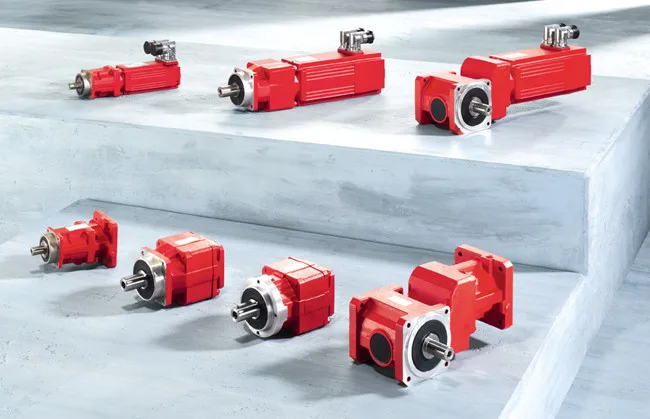

Servo drives are sophisticated control systems designed to manage the movement and operation of servo motors. These drives receive a command signal from a control system, amplify it, and transmit the required electrical current to the servo motor to achieve precise motion. The primary components of a servo drive system include:

● Controller: Processes input signals and sends commands to the motor.

● Servo Motor: Executes the movements as directed by the controller.

● Feedback System: Monitors the motor’s position and speed, providing real-time data to the controller.

● Power Supply: Provides the necessary electrical power for the entire system.

How do Servo Drives Work in 3D Printers?

Servo drives operate through a closed-loop system that ensures accuracy and consistency. Here’s a detailed look at their working principles in 3D printers:

1. Command Input: The 3D printer’s control system sends a command signal to the servo drive.

2. Signal Processing: The servo drive processes the command and determines the necessary action.

3. Current Supply: The drive supplies the appropriate current to the servo motor.

4. Motor Movement: The servo motor moves according to the command.

5. Feedback Loop: The feedback system continuously monitors the motor’s position and speed, sending data back to the controller.

6. Error Correction: The controller adjusts the motor’s movement based on feedback to correct any deviations.

What are the Advantages of Using Servo Drives in 3D Printers?

Servo drives offer numerous benefits that enhance the performance of 3D printers. Some of the key advantages include:

● Precision: Accurate control over motor movement, resulting in finer print details.

● Speed: Faster response times and higher speeds without sacrificing accuracy.

● Efficiency: Optimized power consumption and smoother operation.

● Reduced Errors: Minimized mechanical errors due to real-time feedback and corrections.

● Enhanced Control: Greater flexibility and control over the printing process, allowing for complex and intricate designs.

What are the Key Components of Servo Drives in 3D Printers?

The main components of servo drive in 3D printers include:

● Controller: The brain of the servo drive system, processing inputs and commanding the motor.

● Servo Motor: The actuator that performs the physical movements.

● Feedback System: Ensures accuracy by constantly monitoring and reporting the motor’s position and speed.

● Power Supply: Delivers the necessary power to the entire system, ensuring stable and consistent operation.

Source: a-m-c.com

How Do Servo Drives Improve Print Quality?

Servo drives significantly enhance print quality in several ways. They provide superior print resolution, resulting in finer details and smoother surfaces. Additionally, the precise control over motor movements ensures more accurate dimensions, reducing the likelihood of errors and inconsistencies in the final product.

What is the Difference Between Servo Motors and Stepper Motors?

A servomotor is a rotary or linear actuator that allows for precise control of angular or linear position, velocity, and acceleration in a mechanical system. It constitutes part of a servomechanism and consists of a suitable motor coupled to a sensor for position feedback and a controller. Source: Wikipedia

While both servo motors and stepper motors are used in 3D printers, they differ in several key aspects:

● Precision: Servo motors offer higher precision due to their feedback system.

● Speed: Servo motors can achieve higher speeds without losing accuracy.

● Torque: Servo motors generally provide higher torque, making them suitable for more demanding applications.

● Cost: Servo motors are typically more expensive than stepper motors.

● Complexity: Servo systems are more complex, requiring a feedback loop for accurate operation.

Source: Wikipedia

How to Choose the Right Servo Drive for Your 3D Printer?

Selecting the right servo drive for your 3D printer involves several considerations:

1. Printer Type: Determine the type of 3D printer you are using.

2. Desired Print Quality: Assess the level of detail and precision required.

3. Budget: Consider the cost of the servo drive in relation to your budget.

4. Compatibility: Ensure the servo drive is compatible with your printer’s control system.

5. Technical Specifications: Check the drive’s specifications to match your printer’s requirements.

How to Install and Calibrate Servo Drives in a 3D Printer?

Installing and calibrating servo drives involves several steps:

Required Tools:

● Screwdrivers

● Multimeter

● Calibration software

Installation Steps:

1. Mount the servo drive and motor securely.

2. Connect the drive to the control system and power supply.

3. Install the feedback sensors.

Calibration Steps:

1. Run the calibration software to fine-tune the servo drive.

2. Adjust the feedback system to ensure accurate readings.

3. Test the system to verify proper operation.

What are the Common Issues with Servo Drives?

Some common issues and their solutions include:

● Overheating: Ensure adequate cooling and ventilation.

● Calibration Errors: Recalibrate the system using the appropriate software.

● Motor Stalling: Check for obstructions and ensure proper power supply.

● Noise: Inspect for mechanical wear and tear and lubricate as needed.

What are the Maintenance Tips for Servo Drives in 3D Printers?

Regular maintenance ensures the longevity and performance of servo drives:

● Regular Cleaning: Keep the drive and motor clean from dust and debris.

● Lubrication: Regularly lubricate moving parts to reduce wear.

● Checking Connections: Ensure all electrical connections are secure and corrosion-free.

● Updating Firmware: Keep the drive’s firmware updated to the latest version for optimal performance.

What are the Applications of Servo Drives in Different Types of 3D Printers?

Servo drives are beneficial in both FDM and Resin 3D Printers:

● FDM (Fused Deposition Modeling): Improved layer adhesion and print speed.

● SLA (Stereolithography): Enhanced accuracy in complex geometries.

● SLS (Selective Laser Sintering): Better control over the sintering process.

● DLP (Digital Light Processing): Higher resolution and finer detail in prints.

Incorporating servo drives in 3D printers has shown significant improvements in various applications. For instance, a medical device manufacturer used servo drives to achieve higher precision in producing complex prosthetic components, resulting in a better fit and increased patient comfort. Another example is a custom automotive parts maker who utilized servo drives to enhance the speed and accuracy of printing intricate parts, reducing production time and costs.

What are the Future Trends?

Emerging technologies and advancements in servo drives are poised to revolutionize 3D printing further. Trends include the integration of AI for predictive maintenance and performance optimization, the development of more compact and efficient servo motors, and the enhancement of wireless communication capabilities for easier integration and control.

Conclusion

Servo drives play a crucial role in advancing 3D printing technology. They offer unparalleled precision, speed, and control, significantly improving print quality and efficiency. As technology continues to evolve, servo drives will undoubtedly remain at the forefront of innovations in 3D printing, enabling more complex and high-quality creations.

Read more about desktop 3D printer builds and processes in our basic guide. For a deeper understanding of what 3D printing is, please read the detailed guide on Raise3D or Wikipedia.