I had the opportunity to visit the Cambridge University Department of Engineering and the student-led Riviera Racing team, a group known for its ambitious marine engineering project. This visit was supported by Snapmaker, who provided the team with multi-functional fabrication tools to aid in prototyping.

The highlight of the day was witnessing a full-scale testing session on Grafham Lake, where students launched and evaluated their custom-designed, student-built boat. It was a unique opportunity to see engineering theory come to life through hands-on experimentation.

Table of Contents

- Workshop Visit and Student Project Overview

- Snapmaker in the Workshop

- Real-World Prototyping in Student Engineering

- 2025 Year’s Goals

- Watch the Team in Action (Video)

- Monaco Competition

- Follow the Team

- Final Thoughts & Acknowledgements

Workshop Visit and Student Project Overview

Photo: Max Funkner

The visit began with a guided tour of the Engineering Department led by Matteo Cascini, where I had the chance to see the facilities that support the Riviera Racing team’s work. From prototyping labs to electronics and materials workshops, the department offers a hands-on environment that encourages cross-disciplinary collaboration and innovation.

It was also fascinating to explore other parts of the department and get a glimpse of how things operate at the world-renowned University of Cambridge.

Snapmaker in the Workshop

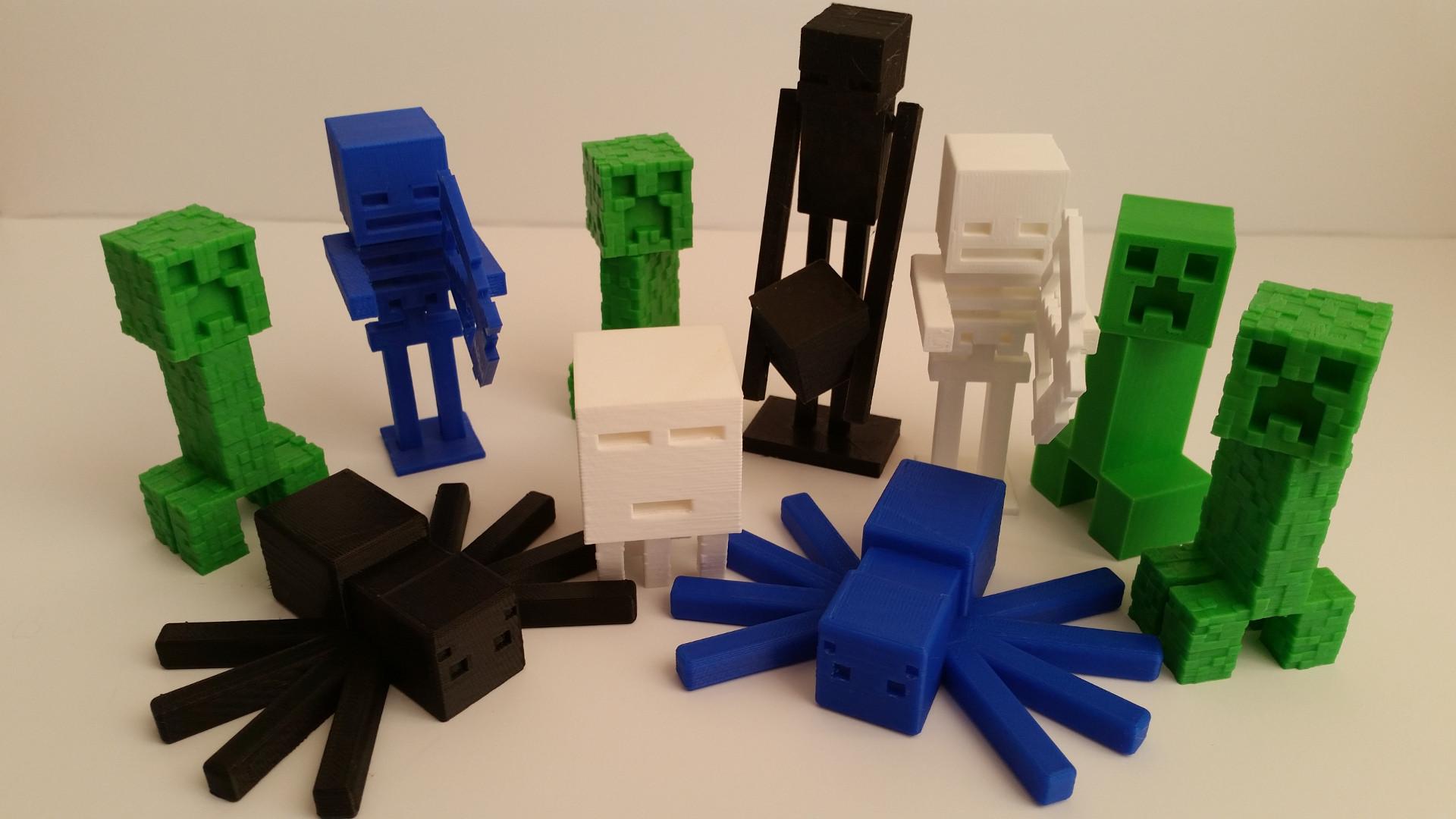

While the boat testing stole the show visually, a quick tour through the department’s workshop revealed some of the tools that made it possible. Among them was the Snapmaker Artisan, a 3-in-1 digital fabrication machine capable of 3D printing, laser engraving, and CNC carving, as well as the Snapmaker J1s – a high-speed IDEX printer.

The list of 3D printed components featured in the project includes:

- Rear structural clamps (replacing heavy plywood blocks)

- Steering wheel mount, steering cable drum, and dashboard screen casing

- Rear steering bicycle wheel mount

- Propeller cavitation plate mount

- Throttle casing

- Hull conversion project spacers and drilling jigs

- Electronics housing in the battery case

- Propeller prototypes

For part design and preparation, the team primarily used SolidWorks for CAD modeling and Snapmaker Luban as the slicing software for 3D printing workflows.

Although not the only machine in use, the 3D printers played a significant role in creating functional prototypes. According to the team, several boat components were produced using PLA filament, including replacement parts that previously utilized wooden elements, such as bracket holders.

Real-World Prototyping in Student Engineering

The student-led Riviera Racing team is working toward a sustainable maritime future by building a zero-emissions boat, which they plan to enter in the 2025 Monaco Energy Boat Challenge, a major marine engineering competition.

– Under Pressure. The team faced a slight delay during the lake testing, as the engine initially failed to start. However, through calm and methodical troubleshooting, they managed to resolve the issue and get the boat running smoothly. This moment not only highlighted their technical capability but also their resilience under pressure — a trait as valuable as engineering itself.

The Riviera Racing team is composed of dedicated students specializing in various aspects of the project. In the group photo, from left to right:

- Karthik Nachippan (Software and Propulsion Engineer)

- Max Funkner (I wish I were a part of the team)

- Harsh Sinha (Co-captain and Director of Operations)

- Matteo Cascini (Body & Structures Lead)

- Sanadi Ilandaridewa (Deputy Chief Engineer: Electrical)

- Oliver Flavin (Pilot and Propulsion Lead)

- Gereon Leckebusch (Propulsion Lead)

- Henry Means (Body & Structures Engineer)

- Max Weston (Deputy Chief Engineer: Mechanical)

Many of the Riviera Racing team members are also active on LinkedIn, making it easy to follow their ongoing projects and professional journeys beyond this initiative.

Riviera Racing’s approach blends academic engineering with real-world design constraints. Seeing a boat transition from CAD to water, with students responsible for everything from electronics to propulsion, showcased the strength of project-based learning.

The project also demonstrated how affordable digital fabrication tools, like those offered by Snapmaker, can empower student teams to iterate quickly and test efficiently.

2025 Year’s Goals

The Riviera Racing team continues to push boundaries with ambitious goals for the current development cycle. Among the key focuses are reducing the boat’s overall weight and improving efficiency through emerging technologies.

They are already exploring the use of hydrofoils, hydrogen fuel cells, and computer vision powered by AI to enhance future designs. Lightweight, custom 3D printed components are expected to play an even greater role as the team works toward optimizing structure and performance.

The team is aiming to conduct two to three additional testing sessions before the competition in Monaco, all while balancing final exams and academic commitments. The Monaco trip itself spans up to seven days, marking a major milestone in their calendar as they prepare to represent Cambridge on an international stage.

Watch the Team in Action

This official video from the Riviera Racing team offers a closer look at their goals, engineering process, and testing experience.

Update: Monaco Competition

In July 2025, the Riviera Racing team successfully made it to the prestigious Monaco Energy Boat Challenge, competing among 20 international teams. Despite an unfortunate electrical failure caused by salt corrosion that prevented them from entering the final race, the team still achieved an impressive 10th place overall. Their preparation, adaptability, and enthusiasm on-site were evident throughout the event. The experience not only marked a major milestone in their journey but also strengthened their resolve for future races, including a planned return in Sardinia this October.

Where to Follow the Team

To keep up with the latest updates from the Riviera Racing team — including behind-the-scenes work, competition milestones, and sustainable engineering developments — you can follow them here:

- Instagram: @cu_rivieraracing

- LinkedIn: CU Riviera Racing on LinkedIn

- Linktree: CU Riviera Racing other Links

Final Thoughts & Acknowledgements

Snapmaker, currently celebrating its 9th anniversary, has clearly chosen a remarkable team to support in Cambridge University’s Riviera Racing. Their blend of technical creativity, collaborative spirit, and drive toward sustainable marine innovation is exactly what digital fabrication technology is meant to empower.

While this article is not sponsored, travel and filming support were provided by Snapmaker to help document the team’s journey. It’s been a privilege to cover their work, and we wish the team the very best of luck as they prepare to compete.

Main Image: Cambridge University Riviera Racing Boat, Students: Max Weston and Sanadi Ilandaridewa

Have questions? Feel free to ask in the comment section below. Want to discuss this project or share your own experience with 3D printing in education, marine design, or student engineering?

Join the conversation in our dedicated forum thread:

Amazing effort and dedication of the Riviera team coupled with sponsors like Snapmaker is what industry needs to accelerate journey towards sustainable and pollution free future. Good luck!