Formula 1 is normally associated with skilled drivers racing against each other in state-of–the-art cars, but it is also about racing against time. F1 is not like any other car racing, here a driver can experience “g” forces of around 5g on acceleration and braking. The competition in this business is so tough that even 0.5% technological advantage can make all the difference. That’s where 3D printing comes in.

3D Printing in Formula 1 – on TCT Show Birminham

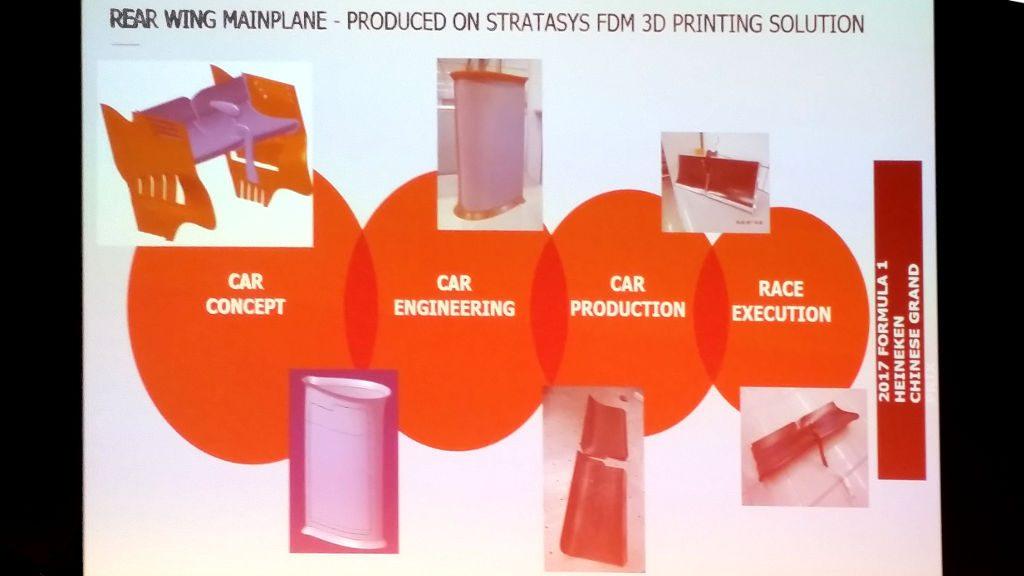

Presenting at the TCT show in October 2017, Simon Roberts, COO at McLaren Racing, called F1 racing “the business of time”. It has brought the company to look at 3D printing as the means to save time on implementing the upgrades and getting the replacement parts in. Their partnership with Stratasys allows McLaren to cut the time of production significantly, in case of the rear wing, for example, the time was reduced by 3 weeks!

(Photo: 3DWithUs)

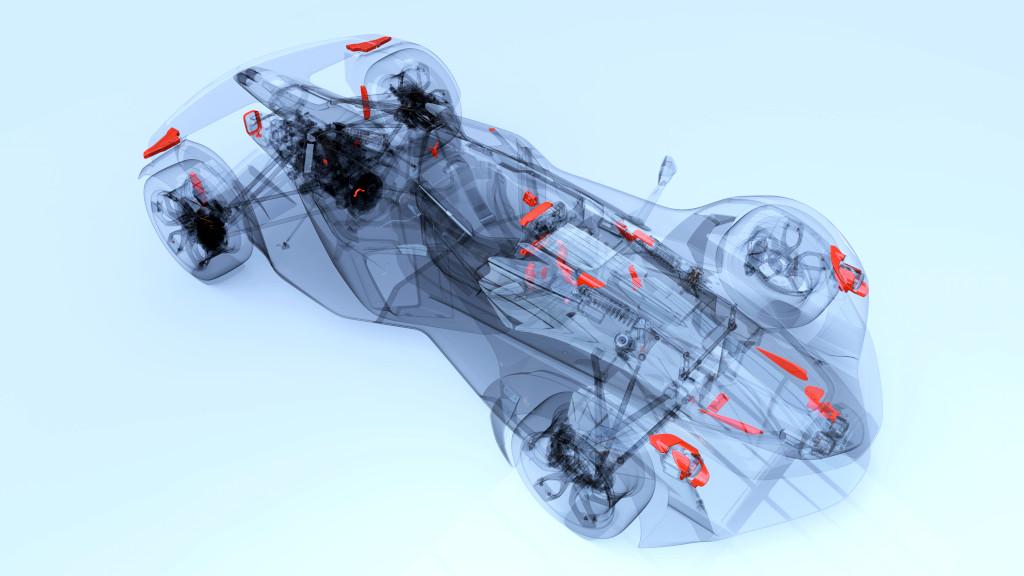

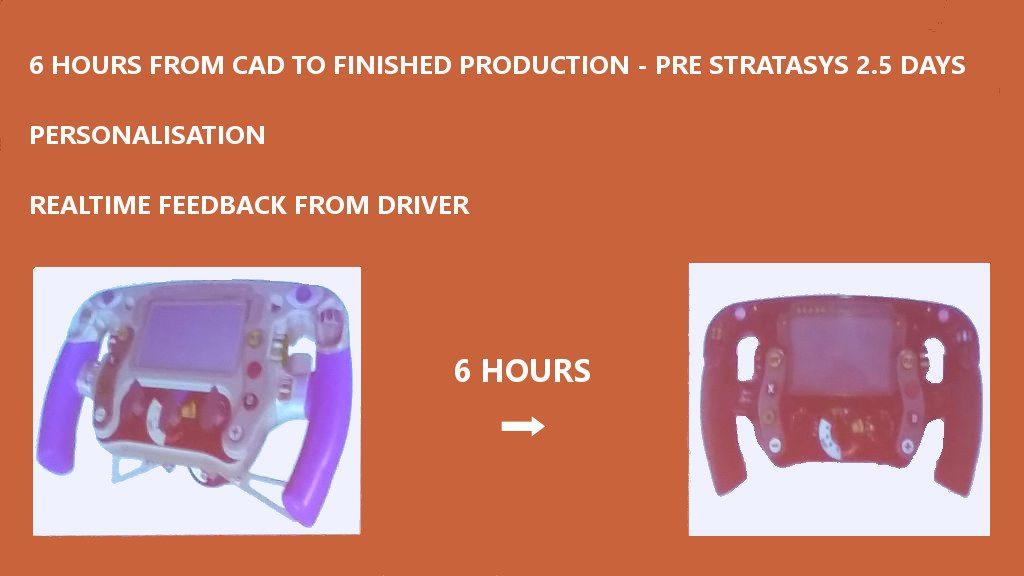

However, 3D printing does not only save time. Before putting a new part into production, it is essential to test it first. With 3D printed prototypes, it became possible to have a quick touch and feel of the mock-up parts. Formula 1 drivers are notoriously picky in regards to their steering wheels.

This is one of the car parts that has to be customised in accordance to the driver’s needs. 3D printing technology allows producing a mock-up steering wheel within 6 hours. The driver can test it and provide a personal, most valuable feedback on what alterations to implement. Prior to 3D printing, it took almost 2.5 days to get a test object.

Since March 2017, Stratasys provided McLaren with over 2,000 parts that were 3D printed on their ProJet equipment. One of the machines now travels with the McLaren team during the racing season, as often particular parts have to be printed on the track.

In the recent years, 3D printing is used more and more extensively in automotive industry. RICOH, traditionally a 2D-printer producer, has launched an industrial machine in 2016, capable to prototype and produce finished parts for cars. According to a RICOH representative, the company intends to start playing a bigger role in Formula 1 business in the coming future.

Read More: 3D Printing Events – List of Shows & Fairs

We’ve put together a table with important 3D printing events, exhibitions and fairs that happened or will happen in near future. Here you can also find a brief coverage of the events made by 3D printing community members. Read more.

(Image: 3DWithUs)

Source & Links:

(Photo: 3DWithUs)

Read More: The Role of 3D Printing in Concept Car Creation

The notion of concept cars involves translating ideas into 2-Dimensional sketches and eventually 3-Dimensional prototypes. The process depicts the future of manufacturing in the automotive industry. Recent attempts at developing concept cars are based on the market’s desire to have functionally intelligent and safe cars. Leaders in automotive engineering solutions strive to use algorithms and cutting-edge technology to actualize concept cars.