Lasers became a very affordable and useful tool that can convert your 3D printer or CNC frame into a laser engraver or laser cutter.

Disclaimer: when operating lasers, it is never enough to stress the importance of the safety measures. The eye-protective goggles and enclosures are recommended while operating any kind of lasers.

Laser Types

There are different types of lasers.

– Dye lasers, for instance, are mostly good for research,

– Co2 lasers with their potent 1000 watt power are able to cut metal,

– Fiber lasers – a big variety of fiber lasers can be used for almost any types of laser cutting and laser engraving. Fiber lasers include impulse and continuous wave (CW) types.

– Diode lasers. In this article, we will tell you more about diode and diode-pumped solid-state laser attachments.

(Source: Endurance Lasers)

The Key Abilities of Diode Lasers – Pros and Cons

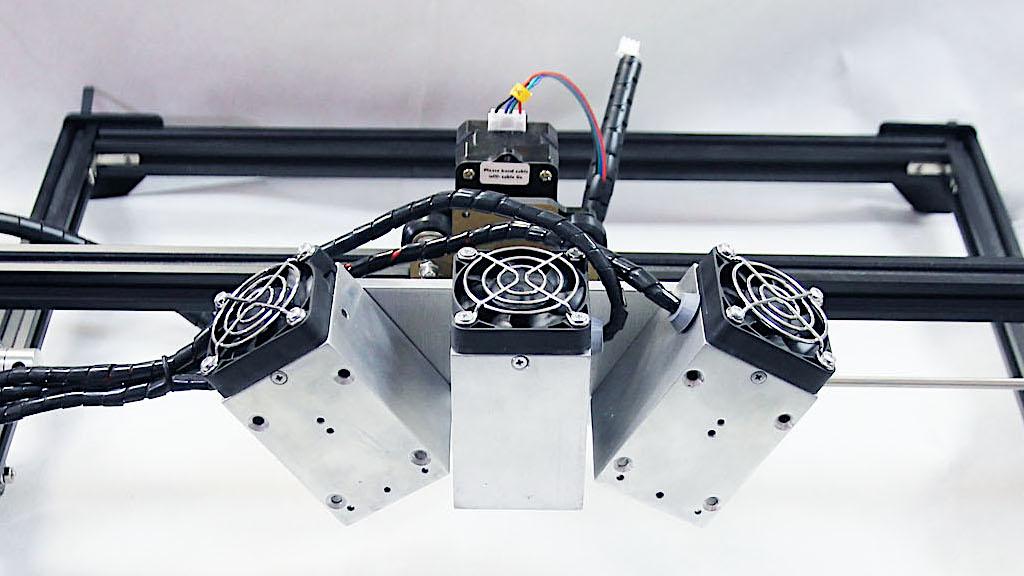

The good thing about diode and DPSS (Diode-Pumped Solid-State) laser heads is that they are portable and can be installed on any 3D printer / CNC frame, unlike Co2 tubes that can not be easily installed on an existing router or 3D printer.

Strong Points

– Soft materials. Diode laser can cut and engrave all soft materials including wood, plywood, leather, cardboard, hardboard, etc.

Most diode lasers with 5W+ optical power can cut wood and plywood up to 3-4 mm (3/8’’) thick if the density is less than 0.5 g/ cm^3. It is very important to know that if the materials are denser then you will need more power for cutting. For example, to cut 3.2 mm (1/8’’) of MDF you will need at least 15-watt optical power to cut it without charring. Read more about density …

– Wood and Polywood. Laser with 5-8 watt CW power cuts up to ¼’’ of wood and plywood, and dark acrylic.

(Source: Endurance Lasers)

– Engraving. Diode lasers can engrave (etching actually) on steel, stainless steel, titanium without any chemicals (engraving paste). To do in-depth engraving you need a DPSSL. A 4-watt DPSSL will be enough to do 0.1 mm in-depth metal engraving (marking).

Diode Laser Weaknesses

– Transparent Materials. It’s a pity that diode lasers cannot cut transparent materials. The problem is the coefficient of the absorption level of acrylic. The acrylic absorbs the laser radiation if the wavelength is more than 5000 nm, Co2 lasers with 10600 nm wavelength cut acrylic easily, while diodes lasers can only engrave.

– Metal Cutting. Another limitation of the diode laser is its inability to cut metal. For metal cutting, you need impulse power or more CW power. Some 150-watt CO2 lasers can cut thin metal with an oxygen assist and a special short focal lens forming a very small laser beam spot. (A 10-watt DPSS can cut 0.2-0.3 mm of brass, copper, aluminum, and steel).

The diode laser can cut up to 3-8 mm of wood/plywood with low density and color acrylic of the same thickness as well as leather, fabric, fiber cloth, cardboard, hardboard, MDF, etc.

The diode laser can etch on stainless steel, steel, titanium without any additional adjustment.

The diode laser can etch on brass and copper with a marking paste such as Cermark, Dry Lube Moly, or thermal CPU paste.

How to Assemble Laser to CNC Frame or 3D Printer

It is easy to wire and hook a laser to an existing CNC frame or 3D printer.

To wire a diode laser or a DPSS laser to almost any CNC frame or 3D printer is an easy process taking only 5-15 minutes. But you need to know what to do.

Most CNC machines and 3D printers have a PWM pin that allows changing the speed of the extruder fan or of the spindle. You may use that pin for wiring the laser. A PWM signal of 3.5V-24V is enough to start and run most of the diode lasers. The Endurance PRO version supports 0-10V analog input as well. You just need to find a PWM pin, which is usually FAN1 on most 3D printers, and a PWM pin on a CNC that is usually used for controlling the spindle speed. After that, you are all set and ready to go.

(Source: Endurance Lasers)

Check an installation of the Endurance laser on Wanhao 3D printer on Instructables.

Why Cheap and Non-branded Lasers are Not a Good Choice

Well, some suppliers do not make enough of testing their products. That is why a lot of people complain about the laser quality and a short life span of their lasers, which is limited to a few months or even weeks. Some unlucky users enjoy their lasers for a few hours only.

There is one more unacceptable thing. Some suppliers lie about the real power output of their lasers.

Even now, while I’m writing this article someone is telling me on Livechat that he saw a Neje (Chinese manufacturer) laser with 40-watt power output. In fact, it is 40-watt power input and the output for that laser might be something like 3-4 watt only 5-watt max if you are lucky enough.

Another bad thing is that some suppliers do not provide support at all, it is always a pain to get any help or assistance, and almost impossible to get a replacement once the laser stopped working in a few months or in a year or something.

Laser Cutting and Engraving Projects

Our company supports makers, hobbyists, and enthusiasts. We run giveaways from time to time and we have a very strong and supportive Facebook community.

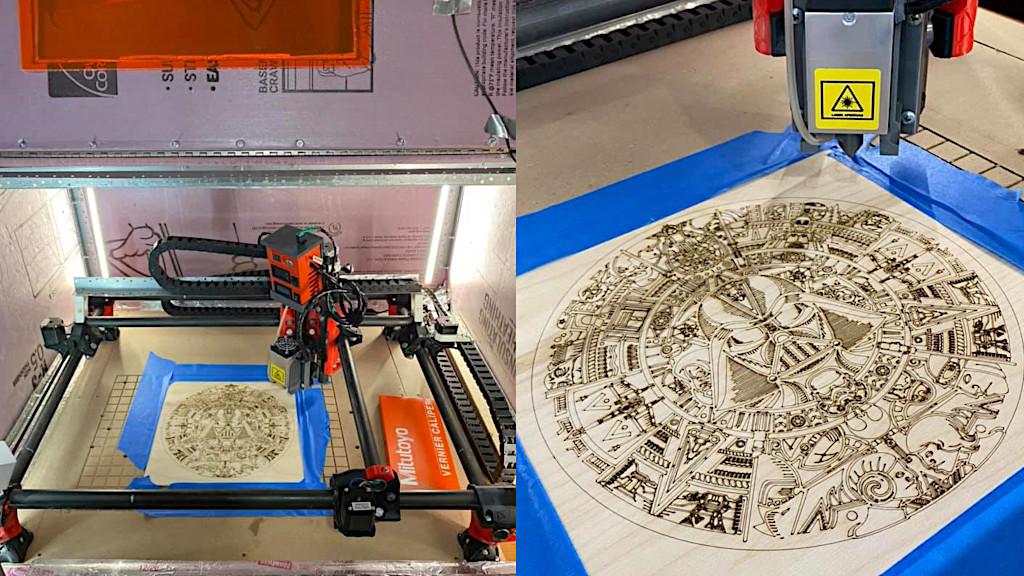

Here are some of the projects that our customers made and shared.

(Photo: Michail Gedeon)

- Endurance Upgrade for ORTUR Laser Master II

- Limit/Homing Switch for CNC3040 Laser Engraver With Endurance 10W Laser Module

- Learn how to design and build my own laser CNC

About Endurance Lasers Company

During the last 5.5 years, we have sold more than 4000 units worldwide.

Last 2 years we ship via DHL express. That means that our customers get their lasers within 3-5 days.

Endurance Lasers LLC is a US-based company registered in Fort Myers, Florida with an office in Naples.

Learn more about Endurance lasers on our official website.

We have a lot of interesting information.

Follow us on social media:

All questions are welcome.

Read more: Laser Cutting & Engraving

Here is a collection of laser cutters and engravers with reviews and technical details. Please feel free to contact us if you would like to add a laser cutter and engraver here or publish your review. You might be a producer or merely an owner, who thinks that a particular machine should be included.

Michael Gedeon’s engraving on the kitchen tiles is outstanding.