Have you heard about a manual injection molding machine? Along with 3D printers, the following device can be a handy tool for manufacturing at home and small business workshops. Let’s take a closer look at the hand operated injection molding and check the machine specifications. We may find out that this could be a highly awaited solution for recycling various plastics, including failed and out-of-use 3D prints.

NB: According to the comments on the campaign page, Alejandro Esquivel failed to deliver the product to some of the backers.

Injection Moding Machine Specifications

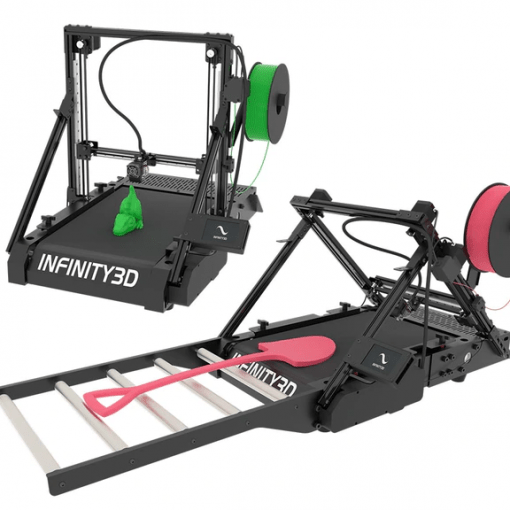

Types: Basic, Professional, Premium, Industrial

Mold Capacity: 12x20x10cm/15x20x15cm/15x20x15cm/20x20x20cm

Plastic Capacity: 80/90/100/180cm3

Min. Wall Thickness: 1.6/1.5/1.5/2.0mm

Max. Temperature 260/265C

Recommended Plastic Type: plastic with a melting index above 12. Mainly: Polyethylene (LD – HD), Polypropylene, TPU, SBS, ABS, TR, Impact PS, crystal PS, PVC flexible, nylon, polyamides, compounds with fiberglass, and more.

Works with, but not recommended: PET, PVC.

Disclaimer: Crowdfunding campaigns – before taking part in any campaign as a backer, please read T&Cs. Rewards aren’t guaranteed.

Hand Operated Injection Molding

You can find a detailed comparison guides about injection molding on our website. It is still the most popular way for mass production of plastic parts and traditionally involves substantial, factory-grade, investment and floor space. Hand operated injection molding devices work based on the same principles but they are much cheaper and can be operated in smaller spaces like a garage or a shed.

Manual Injection Molding Machine

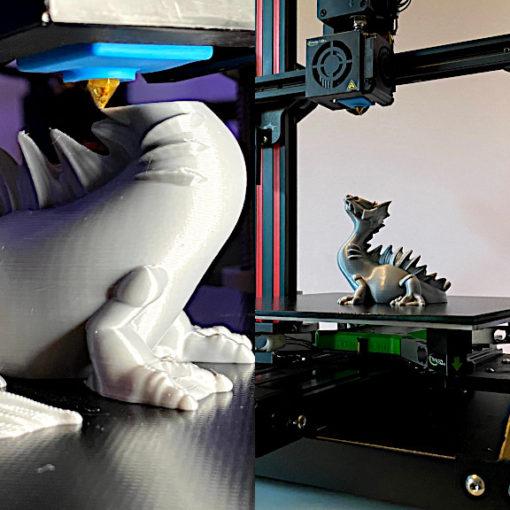

In his Kickstarter campaign, Alejandro Esquivel compares 3D printers to his manual injection molders and lists the Pros for the latter. In his videos, Alejandro demonstrates how the machine melts and turns different kinds of recyclable plastics into solid parts. Plastic bags, bottle caps, packaging bubble wrap, or other plastic materials were turned into new items.

Where to Get the Molds?

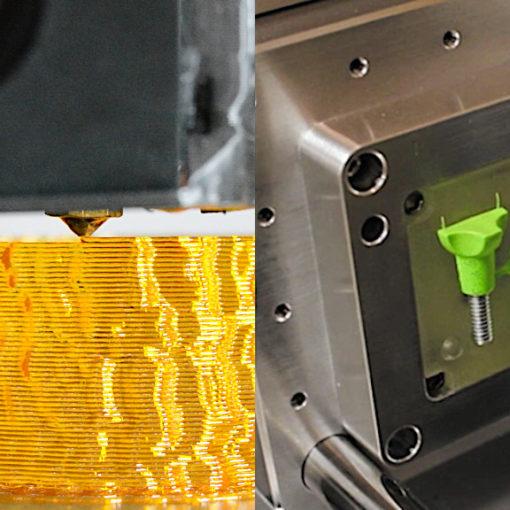

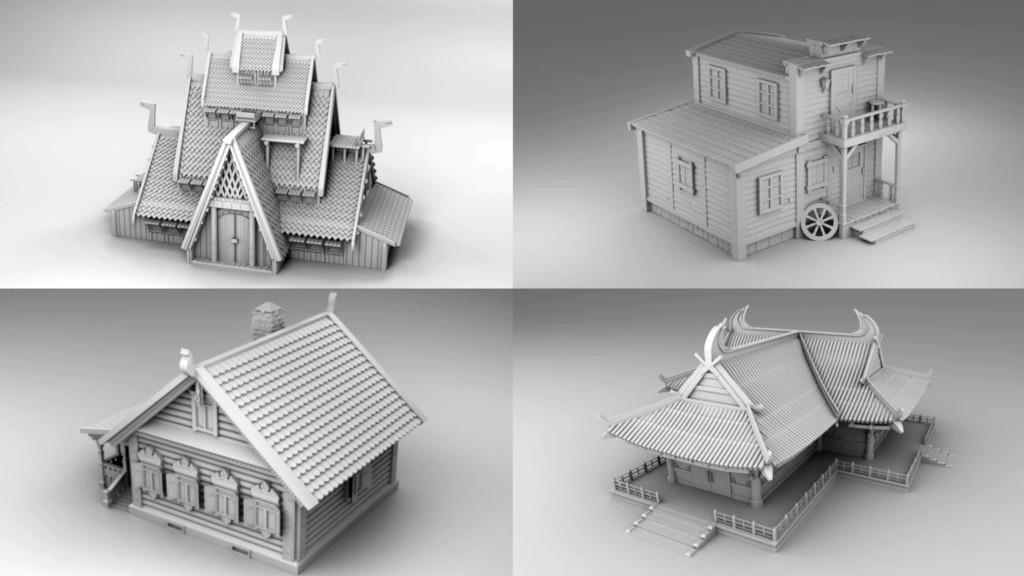

As we understand, it is possible to order a complimentary test mold or a blank mold when acquiring the machine via Kickstarter. Alejandro mentioned that making custom molds will be offered as a service on the official website. Until then, custom molds have to be made using the CNC router machines or, as recommended in the comment section, by using resin 3D printers. Because specific photopolymer resins can withstand high temperatures, they may be suitable for the job.

Solution for Failed and Unused 3D Prints?

While testing and experimenting, 3D printer owners quickly generate a lot of plastic that is not possible to recycle efficiently, yet. Small-scale injection molding at home could be a solution for this growing problem. For example, if filament spools are made from polypropylene, then such plastic could be shredded and injection molded as well.

– Parts in PLA. In the comments, Alexandro stated that even though PLA has a low MFI (Melting Flow Index) it still can be handled using his machines.

Conclusion

As the whole world is moving towards increased sustainability, zero waste manufacturing is a strong trend, and such devices, like plastic shredders and manual injection molding machines, could be a right step ahead in this direction for small-scale production.

As of the moment of writing this post, 126 backers have already parted with their money to have such a device, which shows that there is demand for such machines. And the price doesn’t bite at all.

Read more: Injection Molding

Injection molding has been around for a while now. As a result, in the field of manufacturing, especially in mass production, it is regarded as a go-to option. Injection molding blogs and guides.

I am interested in the hand held injection moulder, does it mix polymer and masterbatch?