Both injection molding and CNC machining are quite the buzzwords in the manufacturing industry. But what you might be wondering about is which process best serves your needs. In this comprehensive guide, we break down some of the main differences between injection molding and CNC machining.

Before we deep-dive into the main differences between the two, let’s recap what each process is.

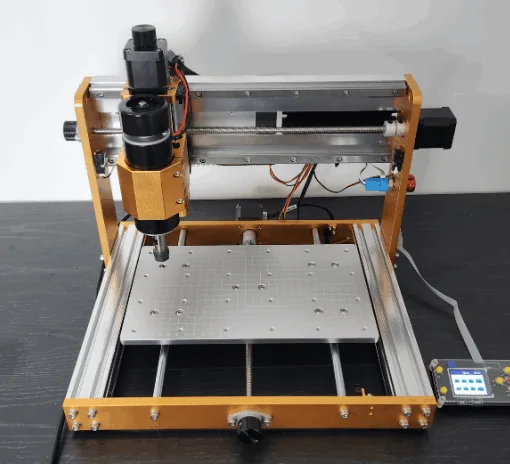

CNC Machining

This is a manufacturing process that obtains the desired product by shaving off layers from a block of material. Here, you take a block of material of your choice and start removing layers from it with great precision. Since it is computer-controlled, you can expect very good results, although it does produce a lot of offcuts.

(Source: CNC Masters)

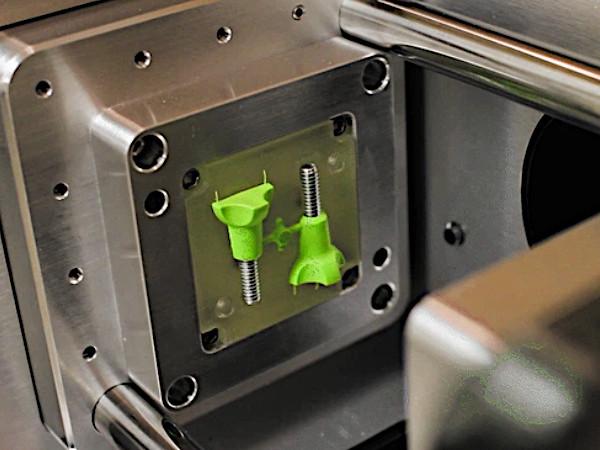

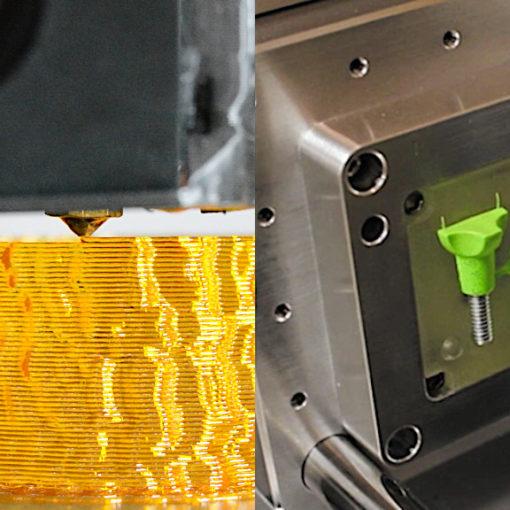

Injection Molding

This process produces the required part by melting the stock material and forcing it into the mold at high pressure. The product is then taken out of the mold after it has cooled and solidified, and the process is repeated again with the same mold.

In some cases, injection molding is unbeatable, for example, clear plastic parts. Have a look at the images via this injection molding service provider.

With that out of the way, let’s take a look at other characteristics that make these processes so different.

The Differences Between CNC Machining vs. Injection Molding

Design

The final design of the end-products plays a huge role when you’re choosing between injection molding and CNC machining. For example, if you are consistent with your design requirements and want a great number of identical parts, injection molding might just be the most cost-effective option for you.

In contrast, if your parts are designed differently, each with its own unique customization, it doesn’t make a lot of sense to create expensive molds that will only be used a handful of times. That’s when you go ahead with CNC machining, where you can design each part differently with no extra cost.

Cost

When we say cost, we mean both per unit and overall price. Think of it like this. The cost of making a part with CNC machining doesn’t vary as you raise the number of parts. This is because manufacturing each product takes its own time and cost. So, for a few parts (less than 100, say), CNC machining is the most cost-effective option.

But as soon as you have a mold ready for injection molding, as you start raising the quantity, the cost per unit goes down significantly. Hence, if you are aiming for a higher volume, it’s best to stick with injection molding over CNC machining.

Note a point of caution here: the upfront cost of creating the mold is quite high. But again, adjusting for a high volume of manufactured end-products, your whole venture should be profitable. On the other hand, injection molding is not nearly as cost-effective as CNC machining when producing a limited number of parts.

(Source: MicroMolder)

Volume and Speed

The number of parts matters a great deal when you try to estimate the efficiency and speed of production. Although fast in production, injection molding can be painfully slow during the mold-making process – taking weeks or sometimes even months.

So, if your part’s volume is small, CNC machining is a faster process. If you need 10 parts in, say, 3 weeks, it is your best choice.

But if you have the mold ready and the parts are in tolerance, or you are sure they will be ready in a short amount of time, that’s when you go with injection molding. In other words, that’s what you do when you want, for example, 40,000 parts in 3 months.

In most cases, the product development teams often use CNC machining to build the first prototype and transition to injection molding if there is high demand. So, whatever your needs are, it is vital that you consult with the experts first.

Material

With many advantages to offer, injection molding does fall short in terms of materials it can work with. The very procedure of injection molding requires it to melt original material into a liquid form before proceeding, and there are not many such suitable materials out there, practically speaking.

(Source: CNC Masters)

On the other hand, since CNC machining works by shaving blocks of monolithic materials, it works on most hard matters. So, go ahead with CNC machining for hard materials like certain plastics, wood, metals, etc. Injection molding shall work best only for soft materials or the ones with practically achievable melting points.

- Read more: The Difference Between 3D Printing and CNC Machining: Pros and Cons

- Read more: Can 3D Printing Replace Injection Molding?

- Read more: What is Urethane Casting? The Basics Explained

Final Thoughts

Machine shops often encounter a wide variety of requests for parts and must understand the various manufacturing processes and their capabilities. Hence, it is generally assumed that they have experience with different materials and will make the best product in a manner that’s efficient and cost-effective.

To summarize, several aspects go into differentiating injection molding and CNC machining processes. So, when you are choosing between the two, it’s best that you double-check your design requirements, the budget, the volume of the product, how quickly you want it done, and the material you will be using.

Good Article