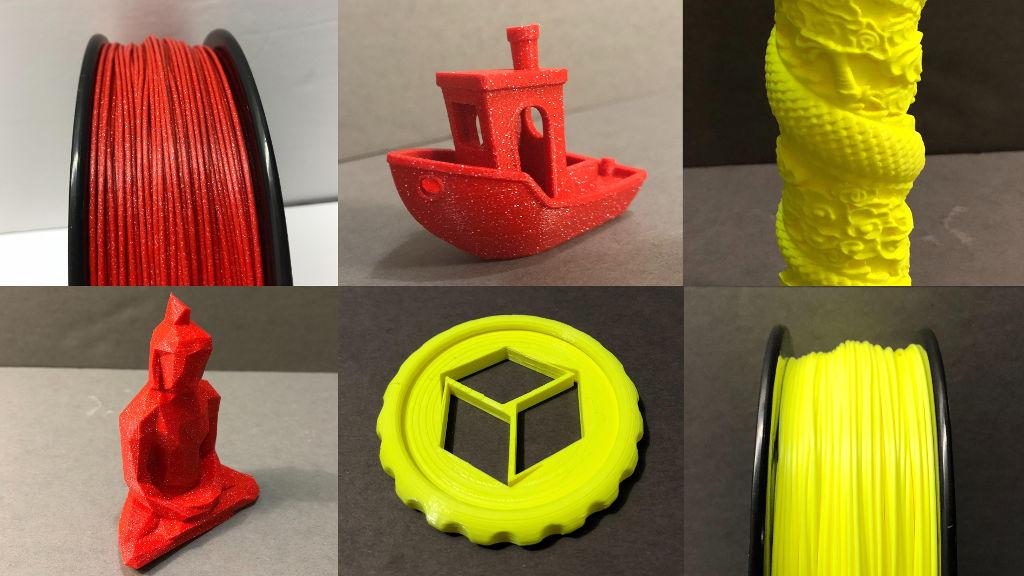

The SUNLU FC01 Filament Connector is designed to provide a solution to the all-too-common problem in 3D printing of partially-used spools with only a small amount of filament left on them. Samples of filament, scraps that are too long to throw away but too short to use easily, and various colors can all be combined using the FC01 to create a usable length of filament. While this unit does have a few quirks, it performed well in testing and would be an easily justifiable purchase for most users.

Printers like the Bambu Lab X1-Carbon can run down spools and automatically switch between them, but only four spools at a time can be loaded and the filament needs to already be on a spool for it to work. The FC01 is currently available for pre-sale at a price of $34.99 directly from SUNLU, making this an inexpensive and attractive accessory for users who are interested in getting the most out of their materials.

Table Of Contents

- Specifications

- Included Accessories

- Splicing Filament

- Printing with Spliced Filament

- Conclusion and Pros & Cons

SUNLU FC01 Specifications:

Filament fusion splicer

Works with 1.75mm PLA, ABS, PETG, PCL, PA, and PC filaments

Price: $35 – $45

Product affiliate links: 3DWithUs is supported by its audience. Purchases via some links may earn us a small commission at no extra cost to you. This helps us to continue bringing you high-quality content. Our guides and reviews remain unbiased and independent.

Included Accessories

The SUNLU FC01 package includes a USB power cord, a bag of approximately 200 PTFE sleeves, and a printed instruction manual. The form factor of the FC01 is very compact, and the overall industrial design of the unit shows attention was given to the user experience. The top plastic lid provides protection from the heated area, and the recessed PTFE sleeve cutter blade is functional without being exposed to the user.

©3DWithUs – Photo: Andrew Sink

Splicing Filament with SUNLU FC01

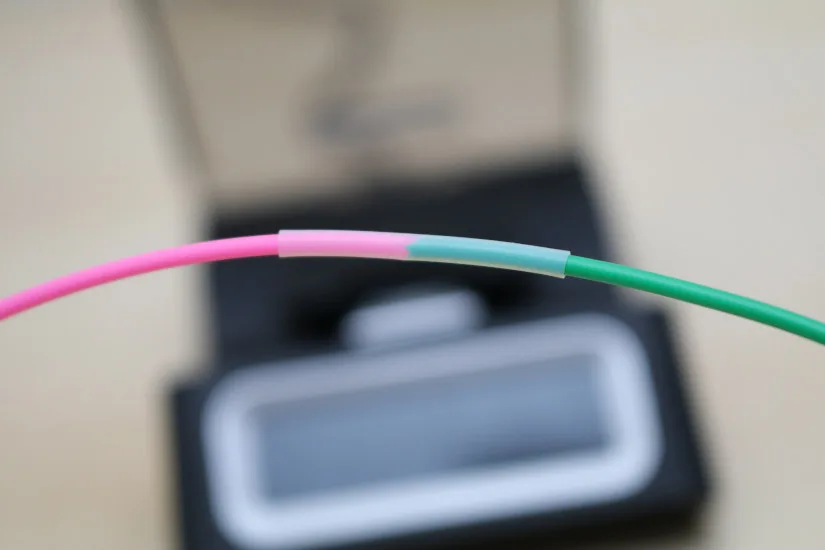

The basic process for splicing filament involves cutting both ends of the filament at an angle to increase surface area, placing a PTFE sleeve over the joint, heating, cooling, then removing the PTFE sleeve. The UI on the FC01 is a small touchscreen that allows users to toggle between filament types (PLA, ABS, PETG, etc.) and adjust the setpoint temperature for the heater. Once activated, the FC01 takes about three minutes to heat up to PLA temperature using the included USB power cord.

©3DWithUs – Photo: Andrew Sink

Once the heater has reached the set temperature, the FC01 will beep to alert the user. Placing the two pieces of filament in the heated area and closing the lid will result in a quick beep, followed by another beep to indicate the heating cycle has been completed. The filament is very malleable immediately after heating, so I found myself being very careful not to move or disturb the spliced area to prevent it from cooling with an undesirable curve.

©3DWithUs – Photo: Andrew Sink

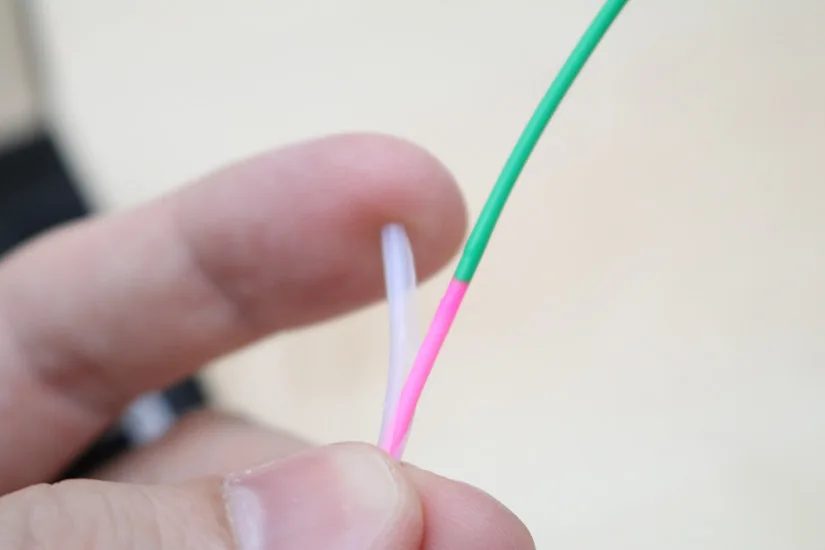

The PTFE sleeve is removed using an integrated cutting blade in the back of the unit. The integrated fixture holds the filament in place during cutting, and the sleeve has a long perforation applied on one side which allows it to be peeled off.

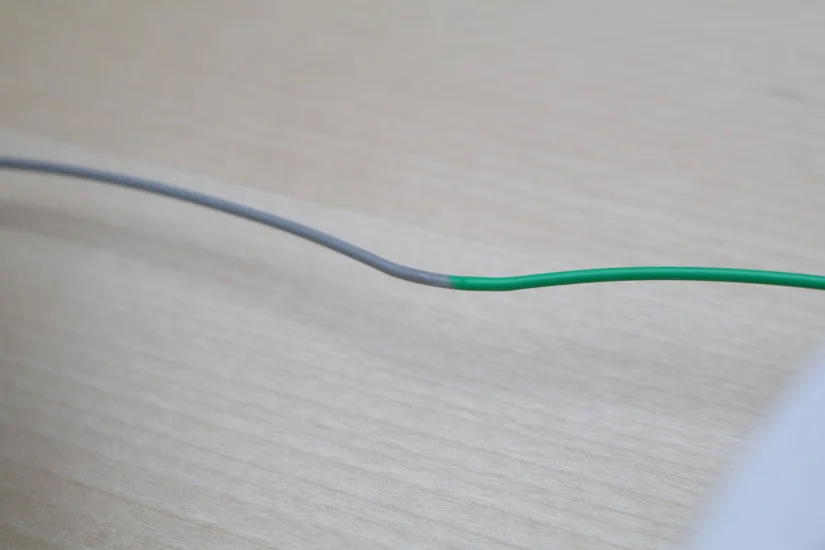

If heated and prepared properly, the joined area on the filament should appear continuous and not have any voids, bubbles, or bulges.

©3DWithUs – Photo: Andrew Sink

Connecting two pieces of filament on the SUNLU FC01 is a task that feels like it requires at least three hands, and I found myself constantly using my elbows and palms to move spools while trying to keep the filament together. Because filament tends to have a smaller radius as you get closer to the center of a spool, joining two spools together and maintaining a continuous arc is a difficult process. This also means that spools need to be manually wound, which is another task that is difficult to accomplish with only two hands and no additional equipment.

Printing with Spliced Filament

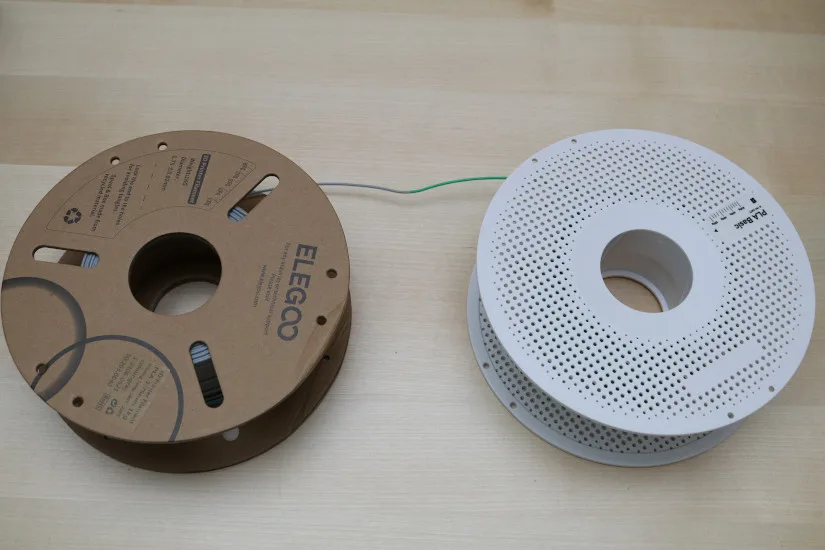

In addition to joining spools of material, the FC01 can also be used to join individual scraps or short lengths of various 3D printing filament into a single piece. Using four scraps of filament (Elegoo Grey PLA, Prusament Ms. Pink PLA, Bambu Lab Basic Green PLA, and Sliceworx Matte Gradient Aquarius PLA), I weighed them together for a total weight of 24 grams.

©3DWithUs – Photo: Andrew Sink

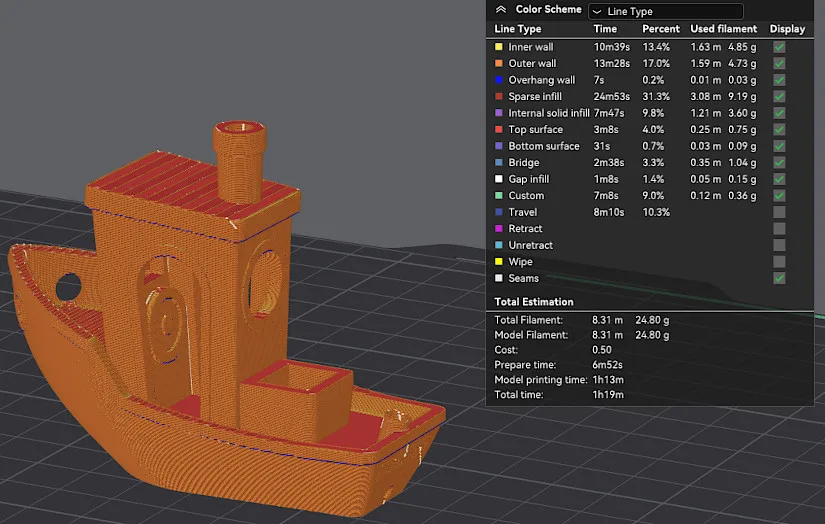

Using BambuStudio, I scaled a 3DBenchy model and adjusted the infill until the estimated filament consumption was roughly 24 grams.

The combined filament was fed directly into a Bambu Lab X1-Carbon via the filament spool holder on the rear, not the AMS. The combined filament printed without issue, and there were no jams, clogs, or other problems apparent during printing. The X1-Carbon smoothly transitioned from one filament scrap to the next, and the final print has layers that are firmly adhered without any obvious weak points or soft connections. I haven’t tested printing with such filament on other budget FDM 3D printers, but there shouldn’t be issues.

©3DWithUs – Photo: Andrew Sink

The final result is impressive, but it’s worth noting that joining these filament scraps required the use of 5 PTFE sleeves (4 for the filament, 1 which was not cut fully and needed to be reattached). The FC01 includes a total of roughly 200 PTFE sleeves, meaning I have about 39 more similar prints before needing to purchase or create new PTFE sleeves. In addition, the PTFE sleeves are a consumable that are disposed of after use, which stands in direct contrast with SUNLU’s tagline “Achieve efficient printing projects with zero waste”.

Compare Filament Splicers

Filament splicers comparison guide coming soon…

Conclusion and Pros & Cons

The SUNLU FC01 Filament Connector is currently offered at a retail price of $44.99, with a pre-sale price of $34.99 directly from the SUNLU site. US orders are scheduled to ship between September 13-30th, while orders to the EU are scheduled in two staggered batches for October 31st and November 20th, respectively.

SUNLU Filament Connector FC01 Review

Review Summary

Considering the relatively low cost of the FC01, it’s an easy accessory to justify for print farm operators or power users who use large quantities of filament and frequently find themselves with partial spools. Welding together small scraps of filament is also possible with the FC01, but the included 200 pieces of PTFE tubing will need to be replenished over time for long-term use. Holding the filament in place during splicing can be a challenging process, and a fixture or jig for holding the filament steady and preventing it from winding back on to a spool would be beneficial.

PROS:

– Inexpensive

– Very quick heating process

– Small form factor

CONS:

– PTFE tubes are a consumable

– Difficult to hold filament in place during splicing