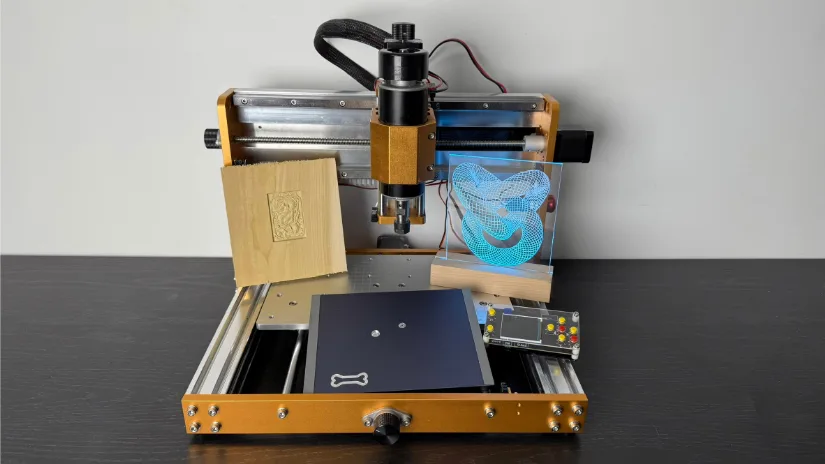

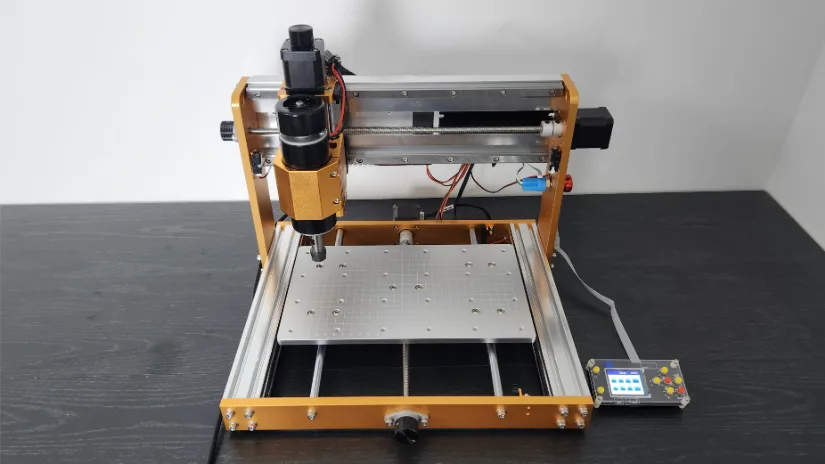

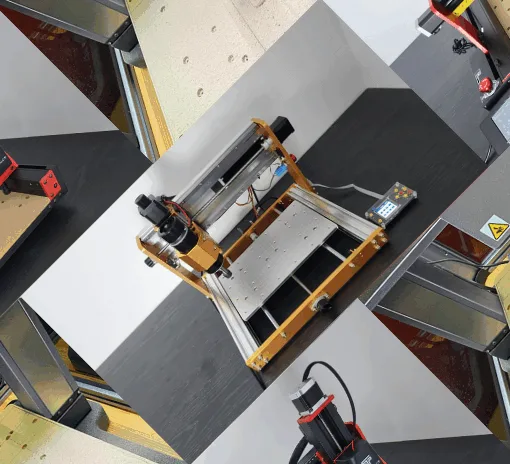

The Lunyee 3018 Pro Ultra is the latest entry in the ever-crowded ‘3018-class’ desktop CNC arena, but it arrives with genuinely upscale touches: a rigid all-aluminum frame, an HGH15 linear-guide X-axis, and a punchy 500 W spindle capable of 5000 mm/min rapids—specs that promise cleaner cuts in everything from hardwoods to soft metals. Its 300 × 180 × 80 mm work envelope maintains a workshop-friendly footprint, while GRBL 1.1f control (with limit switches, an emergency stop, and an optional laser module) ensures seamless integration into familiar DIY workflows such as Candle, UGS, or LightBurn.

In our review, we’ll examine whether these headline features translate into real-world accuracy, ease of assembly, and day-to-day reliability—and just as importantly, identify any compromises lurking beneath the surface. Expect a balanced look at the Pro Ultra’s strengths (rigidity, power) and weaknesses (workspace limitations, noise levels, setup quirks), helping you decide if this compact workhorse deserves a spot on your bench.

Table of Contents (Jump to a Section)

- What’s in the Box

- Specifications

- Setup and Design

- Software

- Results

- CNC Router Bits and Accessories

- Compare to other CNC Machines

- Conclusion and Pros & Cons

Where to Buy the Lunyee 3018 Pro Ultra

Price: $449.00 – $499.00

Compare the Prices & Bundles:

Official Website | AliExpress | Amazon

What’s in the Box

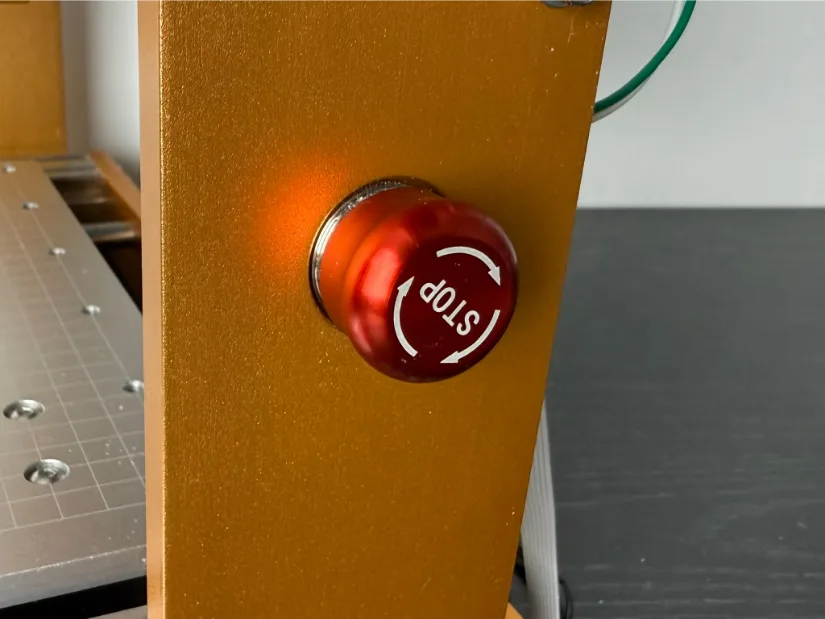

The package includes a Y-Axis module, X-Axis module, 500 W spindle, control board, power supply, four limit switches, a spindle wire clamp, emergency stop switch, Z-Axis probe plate, offline controller, power cable, USB cable, assembly hardware, user manual, USB drive, router bit set, two platen clamps, a brush, and a ruler.

©3DWithUs – Photo: Will Zoobkoff

Specifications

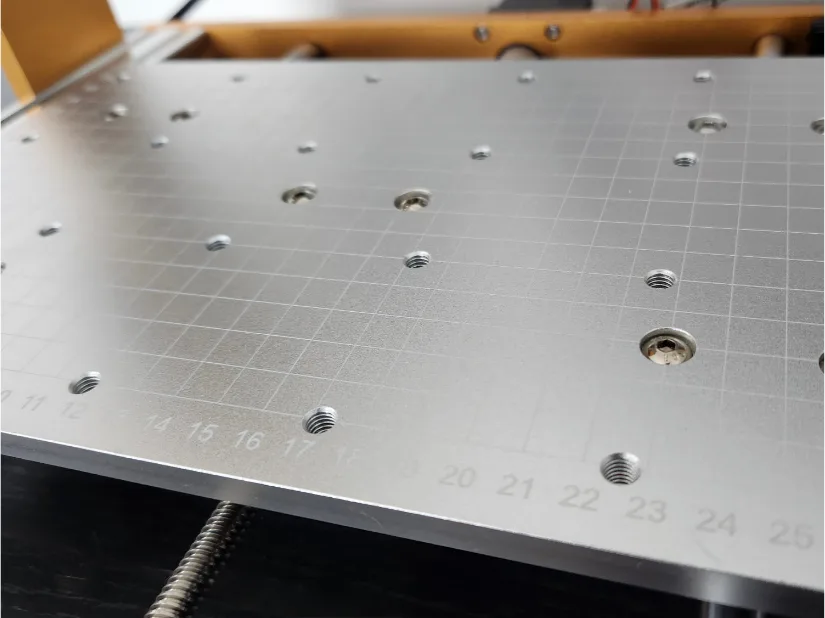

- Work area: 300 × 180 × 80 mm (11.81 × 7.09 × 3.15 in)

- Machine footprint: 422 × 414 × 350 mm (16.61 × 16.30 × 13.78 in)

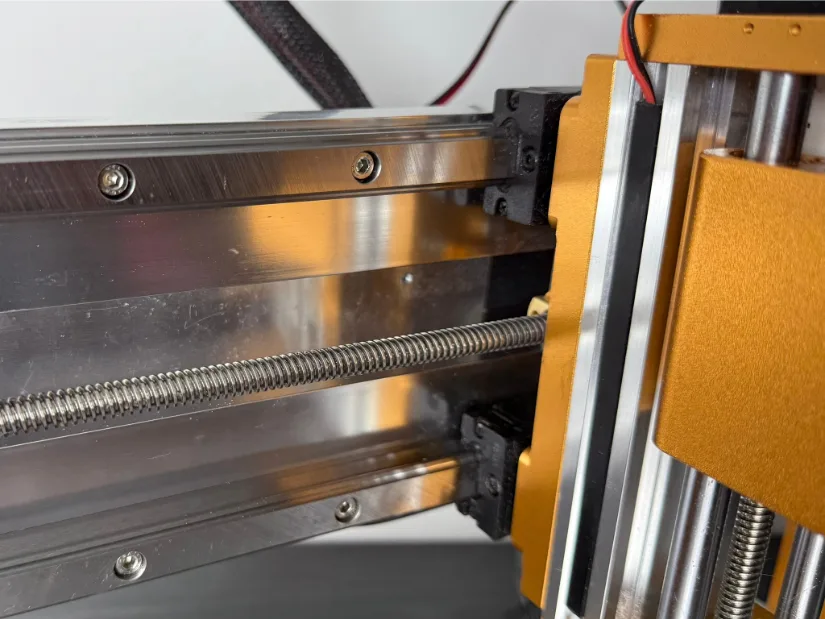

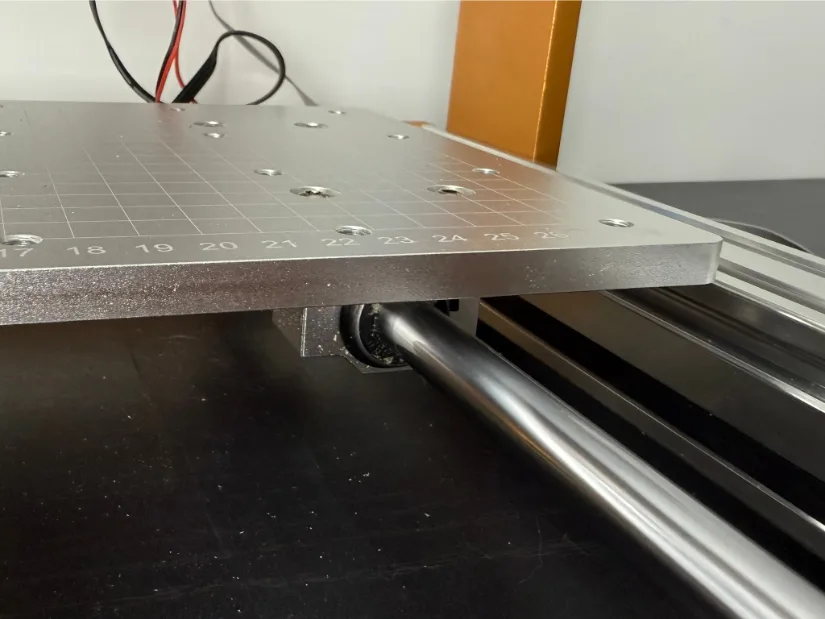

- Frame & motion: All-metal aluminum-alloy and carbon-steel chassis with reinforced 2040/4040 extrusions, HGH15 linear rail on the X-axis, optical shafts on Y/Z, and lead screws on all axes

- Spindle: 500 W (48 V) brushed motor with ER-style collet, suitable for wood, plastics, and light-duty metal work

- Controller board: 32-bit GRBL 1.1f board with 4-axis support, laser and air-assist ports, six limit switches, and an emergency-stop button

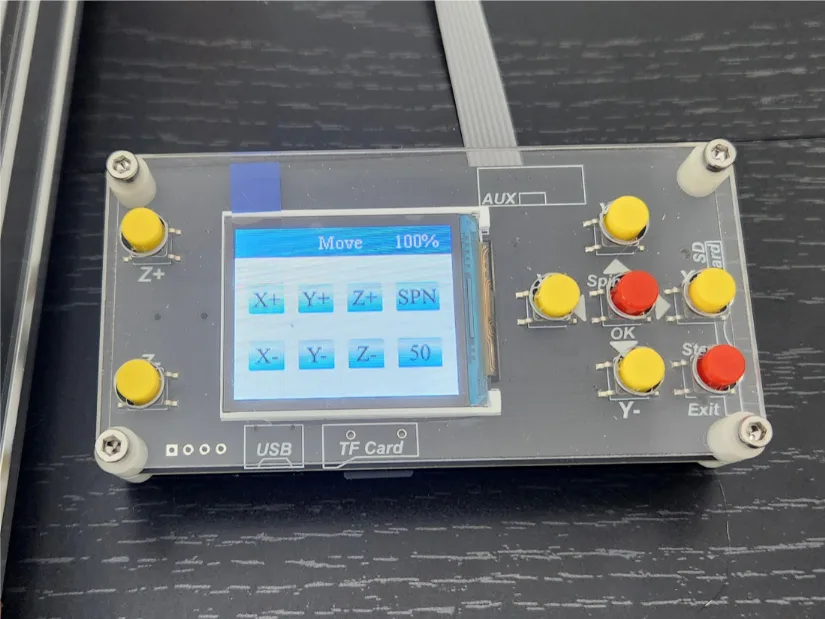

- Offline controller: Handheld pendant with 1.8-inch display and SD/USB support for computer-free operation

- Power supply: Integrated 48 V / 500 W switch-mode unit, selectable for 110 V or 230 V input

- Net weight: Approximately 14 kg (31 lb)

- Software compatibility: Easel (used in testing), Candle, UGS Platform, LaserGRBL, LightBurn, Fusion 360, Vectric VCarve, Carveco Maker, and other GRBL-based CAM software

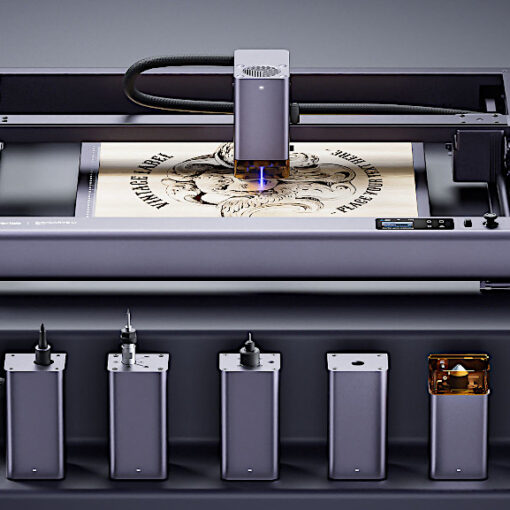

- Optional upgrades: 5.5 W or 10 W laser modules, air-assist pump, dust shoe, and expanded bit kits

Setup and Design

To set up the Lunyee 3018 Pro Ultra, begin by unpacking the machine and checking every component against the parts list, then bolt the pre-assembled XZ gantry to the Y-axis base and level the frame with the supplied rubber feet. Install the limit switches, emergency-stop button, and 500 W spindle—leaving roughly 25 mm of the spindle below the clamp—before mounting the GRBL control board and 48 V power supply, ensuring the PSU’s voltage selector matches your mains.

Connect the labeled cables for the steppers, limit switches, spindle, and (optionally) the offline controller, bundling them neatly out of the machine’s travel path. Release the emergency stop, power on the unit, and link it to your computer via USB; if prompted, install the CH340 driver, open your preferred G-code sender (Candle, UGS, or LightBurn), set the COM port to 115 200 baud, and verify the board responds to a $$ command. Home the machine with $H, confirm each axis moves in the correct direction, surface or tape down a sacrificial spoilboard, probe zero, and run the sample logo file to complete a first test cut—going from box to successful carve in about an hour.

©3DWithUs – Photo: Will Zoobkoff

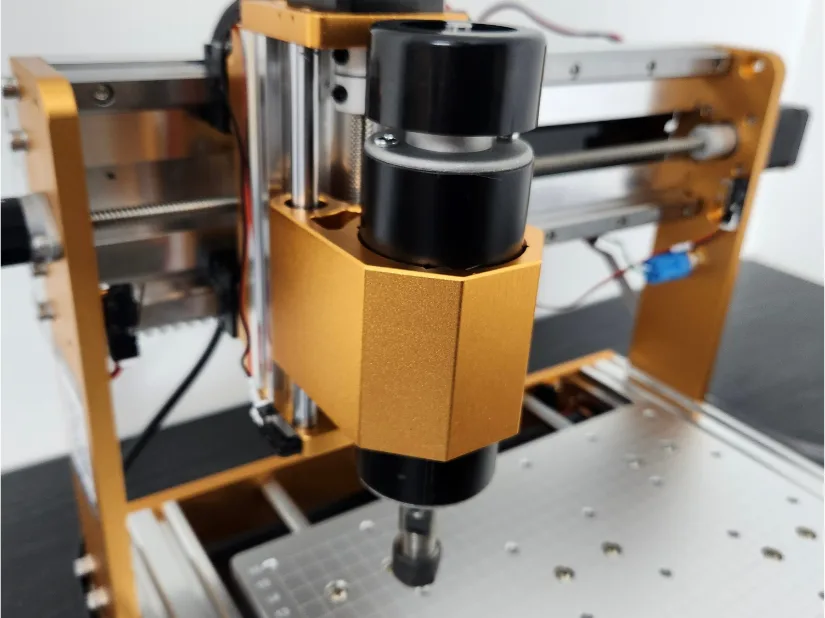

The 3018 Pro Ultra’s design feels a notch above typical hobby-grade 3018 kits: a rigid, mostly aluminum chassis with beefy extrusions and a linear-guide X axis that cuts down on flex and chatter, giving the 500 W, 48 V spindle a stable platform to actually use its extra torque. That spindle is a meaningful upgrade over the usual low-power 775/60–120 W can motors—its higher rotational consistency under load lets you push feed rates in hardwoods and even attempt cautious passes in softer metals without the bogging or burning you’d expect from lighter units.

©3DWithUs – Photo: Will Zoobkoff

Cable management is tidy out of the box, with a braided main harness and clearly labeled connectors that reduce setup guesswork and keep wiring clear of travel. The included offline controller (a small handheld pendant with a color screen and SD/USB access) reinforces the “bench appliance” feel: you can jog, set zero, load G-code, and kick off a job without tethering a laptop, which is great for cramped shops or when you want to isolate a dusty machining environment from your primary computer. Altogether, the combination of stiffer frame elements, a genuinely capable spindle, and convenient standalone control elevates the Pro Ultra from “entry toy” to a compact, purpose-ready desktop CNC.

Software

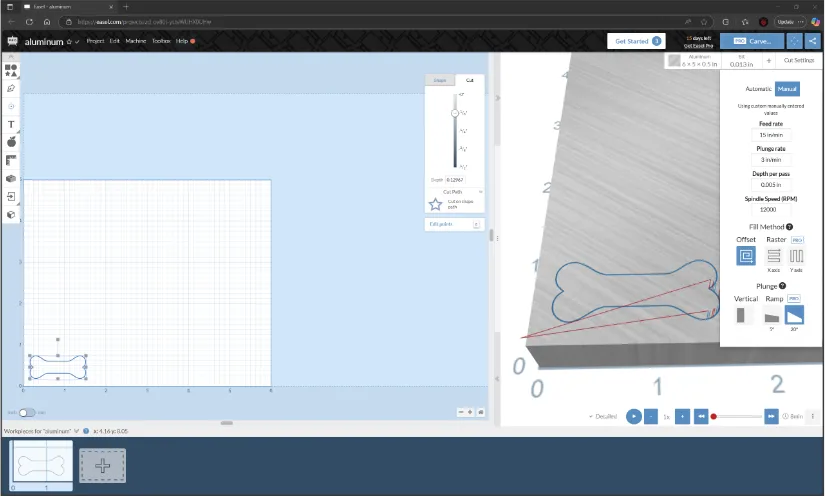

The Lunyee Pro Ultra runs standard GRBL 1.1f firmware, so you have plenty of workflow choices. For my tests, I used Inventables’ cloud-based Easel, which combines design, CAM, and machine control in a single browser tab—handy for quick sketches, tool-path previews, and one-click post-processing to GRBL G-code. If you prefer a lightweight desktop sender, Candle (a favorite among first-time 3018 owners) or UGS Platform offer responsive jogging, macros, and live overrides without the subscription layer.

Makers who pair the machine with an optional laser module often gravitate to LightBurn or LaserGRBL for more refined raster engraving and image tracing tools. For deeper 2½-D carving and V-carving, full-featured CAM suites like Vectric VCarve, Carveco Maker, or Fusion 360 let you create advanced tool paths and then stream the resulting G-code with any sender—or simply drop it onto the SD card for the included offline controller to run untethered. Whichever route you choose, GRBL’s broad compatibility means the Pro Ultra slots comfortably into everything from browser-based beginners’ apps to professional-grade CAD/CAM pipelines.

Testing Results

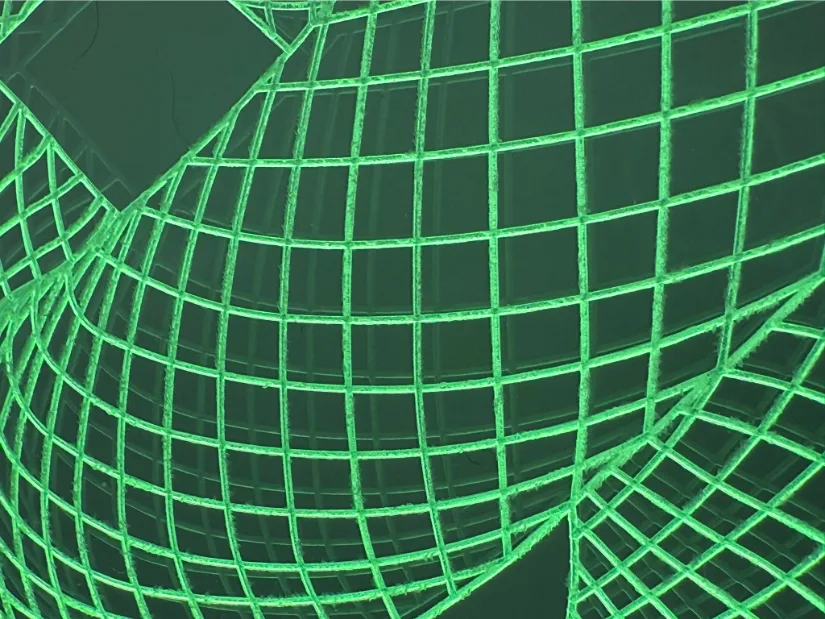

Acrylic lamp

For our first test cut, we created an edge-lit acrylic lamp panel featuring a crisp geometric pattern. Using a 60-degree V-bit at a conservative feed rate of 40 in/min, the job finished in just under an hour, leaving flawlessly sharp, uniform lines with no visible deviation—a testament to how well CNC routing suits acrylic engraving.

©3DWithUs – Project and Photo: Will Zoobkoff

– Tips. Always place a sacrificial wooden spoilboard underneath the sheet to protect the work surface and the finished part. Even though acrylic engraves cleanly, it is still susceptible to chatter and edge blow-out when cut through. Using low-tack adhesive or double-sided tape to secure the blank reduces vibration and stops the material from creeping during longer passes, guaranteeing that those precise geometric details remain in place.

Wood Dragon carving

Our second test focused on a wood carving of an ornate dragon, 2.5D relief included on the USB drive that came with the Lunyee 3018 Pro Ultra. We mounted a 60 degree V bit and we used a piece of poplar wood, we used Candle to send the carving to the CNC from our laptop. The carving took 4 hours to complete due to the number of passes needed to complete the piece. This carving showcases the accuracy and ability for fine movement due to the extremely small point of the V bit being used, but with this bit, you can achieve some really fantastic, extremely detailed relief carvings.

The feed rate we used was 19 in/min, but it could easily be done at a higher rate than the 500W spindle and the solid linear rails on the X axis. The Lunyee 3018 Pro Ultra is a fantastic machine if you are interested in wood carving and cutting.

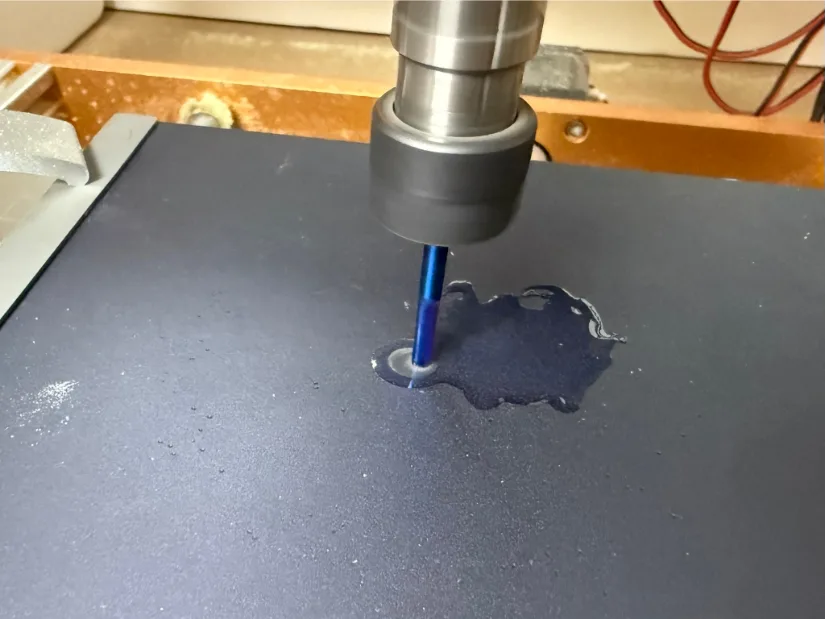

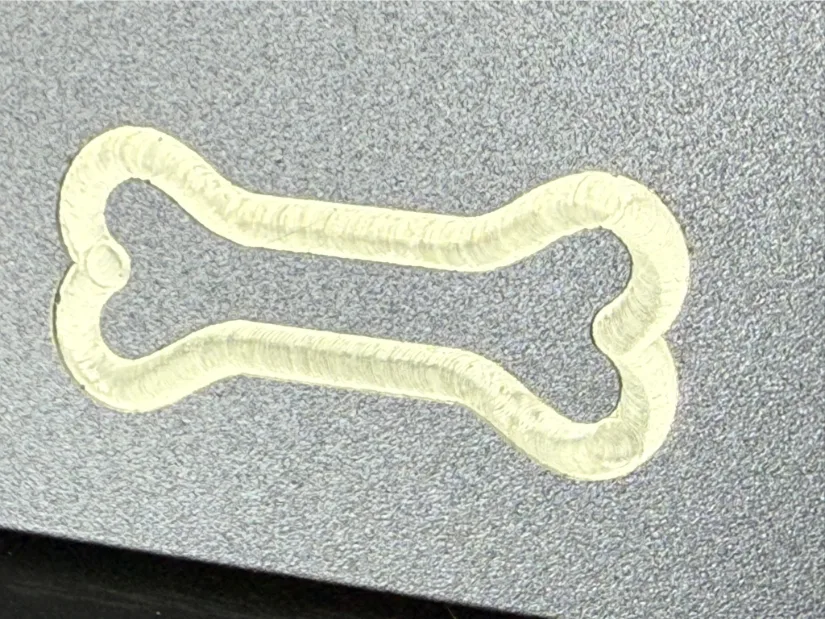

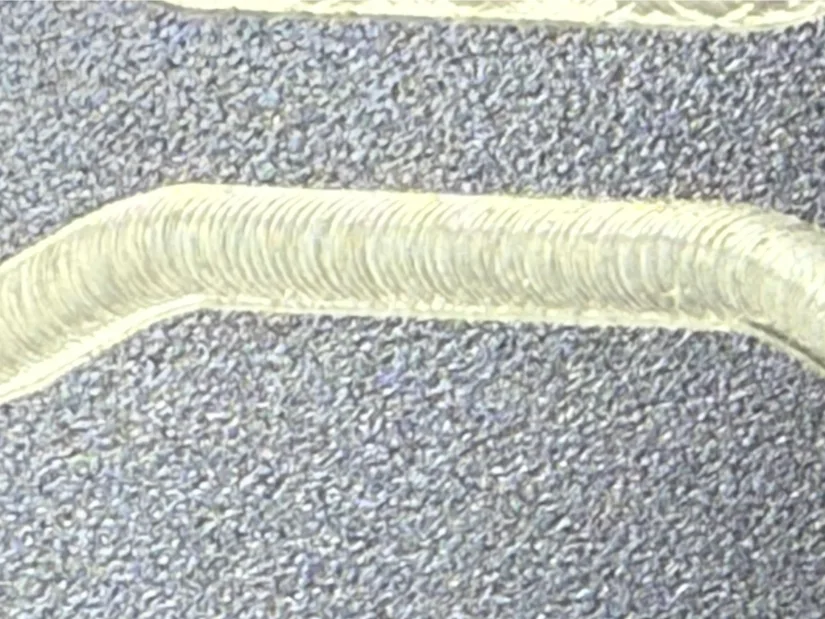

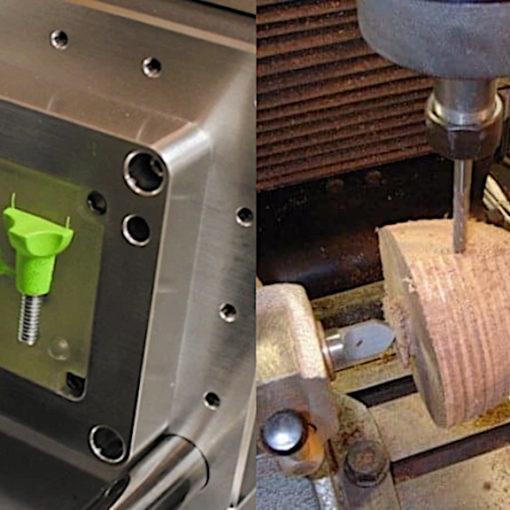

Aluminum Testing

Thanks to the Pro Ultra’s 500 W spindle, the machine can handle light aluminum work. Although purpose‑made non‑ferrous cutters are ideal, we experimented with a tungsten‑carbide bit—serviceable but not perfect. Because aluminum is far less forgiving than wood or acrylic, we dialed the plunge rate down to 3 in/min and kept the feed conservative at 15 in/min, which produced chatter‑free cuts. A drop of cutting oil between passes helps clear chips and prevents galling, especially when using sub‑optimal tooling.

©3DWithUs – Photo: Will Zoobkoff

– Tips. Always place the sheet on a sacrificial spoilboard to protect the bed, and secure it firmly—double‑sided tape or low‑profile clamps keep the part from shifting or ejecting once the cut frees it. With these precautions, the engravings came out smooth and accurate, free of binding, even though the bit wasn’t the best quality bit for aluminum. A purpose‑built aluminum end mill would allow you to increase both feed and plunge rates, significantly reducing overall machining time.

CNC Router Bits and Accessories

When using the LUNYEE 3018 Pro Ultra, having the right CNC router bits is crucial for achieving clean and precise results. LUNYEE offers a range of compatible bits, including spiral bits, engraving tools, and carving sets—all designed for different materials like wood, plastics, and soft metals. Whether you’re working on intricate detail or bulk material removal, there’s a bit tailored for your task.

A variety of CNC bit sets are available directly from LUNYEE’s official store, including essentials like the 5-piece carving kit, 10-piece general-purpose set, and single specialty tools such as the bowl & tray bit. All these CNC bits and extra accessories, such as fixtures, are also available on their Amazon store. These accessories are not only compatible with the 3018 Pro Ultra but also optimized to make the most of its 500W spindle power, enhancing both precision and efficiency in your CNC workflow.

Compare Lunyee 3018 Pro Ultra to other CNC Machines

LUNYEE offers a wide selection of CNC machines on its official website, ranging from entry-level desktop units to more advanced models, such as the CNC 1325 Pro, priced at $6,900. Many of these machines come with optional laser modules and are available in different bundle configurations to suit various needs. You can explore all available CNC router options directly on the LUNYEE website.

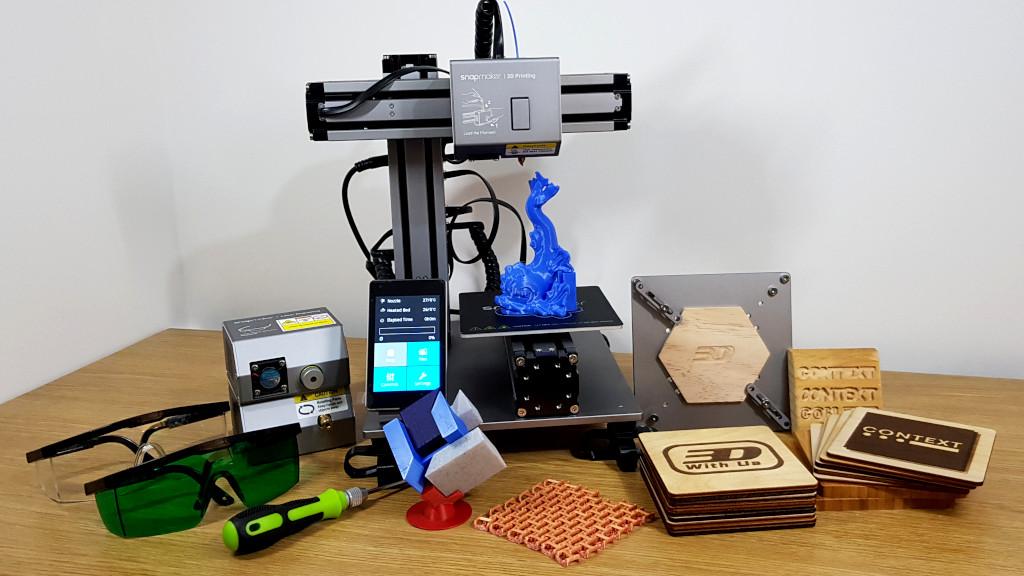

Previously on 3DWithUs, we explored CNC carving using the Snapmaker A350T. While the Snapmaker offers a versatile 3-in-1 platform with a 200W CNC module, the LUNYEE 3018 Pro Ultra stands out with its dedicated design and more powerful 500W spindle, making it better suited for heavier-duty carving tasks.

For a comparison with other CNC machines, please refer to the detailed CNC Machines guide. (coming soon).

©3DWithUs – Projects and Photo: Will Zoobkoff

Have questions? Feel free to ask in the comment section below.

For a wider discussion or to share your own CNC projects, join us in the forum:

Conclusion and Pros & Cons

Compare the Prices & Bundles:

Official Website | AliExpress | Amazon

Lunyee 3018 Pro Ultra Review

Review Summary

After cutting crisp acrylic lamp panels, sculpting a poplar relief, and cautiously nibbling away at aluminum, the Lunyee 3018 Pro Ultra proves it’s far more than a ‘starter toy.’ Its rigid all-metal frame, beefy 2040/4040 extrusions, and linear-rail X-axis give the 500W spindle the stability to hold tolerances and leave clean edges, whether you’re V-carving plastic, roughing hardwood, or making shallow passes in soft metals.

The bundled handheld controller and SD slot mean you can jog, set zero, and run jobs untethered—turning the unit into a true bench-top appliance that keeps dust and chips well away from your laptop. Admittedly, the 300 × 180 mm work area and a noticeable uptick in spindle noise remind you this is still a compact desktop machine, and aluminum work demands slower feeds, cutting oil, and carbide tooling. Yet for makers who want an affordable CNC that bolts together in about an hour, slots seamlessly into any GRBL-based workflow (Easel, Candle, LightBurn, Fusion 360, you name it), and doesn’t immediately beg for aftermarket stiffening plates or electronics swaps, the Pro Ultra lands squarely in the sweet spot. If your projects fit its envelope—and you fancy the occasional spindle or laser upgrade—it’s an easy machine to recommend.

Pros

- Rigid all metal frame

- 500W spindle

- Offline controller

- Price

Cons

- Limited workspace

- Included bits limited

Has anybody actually got a 4th axis running on this. I’ve found a few on AliExpress and messaged Lunyee but they’re telling me the machine isn’t compatible.