3D printing has already transformed prototyping, manufacturing, and even home décor, and now it’s stepping confidently into footwear. For me, as someone who has spent more than a decade surrounded by additive manufacturing, trying a fully 3D printed pair of shoes feels both exciting and strangely personal. PollyFab’s lattice shoes are a great example of how advanced 3D printing can meet everyday fashion in a practical, wearable form. I tested them over several weeks, including a real-world “torture test” at the Formnext trade show in Germany, to see how they perform in terms of comfort, design, and day-to-day usability.

Table of Contents (Jump to a Section)

Introduction

Design and Lattice Structure

Bare Feet or Socks?

Comfort and Fit

Formnext Real-World Test

How PollyFab Shoes Are Made

Conclusion and Pros & Cons

Where to Buy

Aero

Price: $89.99 – 149.99 USD

Compare the Prices & Discounts:

Official Website

Flux

Price: $119.99 – 199.99 USD

Compare the Prices & Discounts:

Official Website

Design and Lattice Structure

PollyFab’s shoes are made entirely through 3D printing, using a flexible lattice geometry that replaces the need for traditional soles, insoles, and stitching.

The open mesh pattern allows air circulation and gives the shoes a springy, cushioned feel. Available in black, white and orange, they arrive neatly boxed with stuffed interiors to maintain shape.

©3DWithUs – Photo: Max Funkner

I was especially impressed with the black Flux from the beginning. I originally asked for the striking orange version, but it was unavailable. When the black pair arrived, I liked the look almost instantly. The design clearly says that it is 3D printed, and after more than ten years in this industry, that alone gives me a real dopamine kick. It even reminds me of the feeling I had as a kid when I saw the black Knight Rider car. The shoes have a similar cool and futuristic vibe that feels strongly connected to additive manufacturing.

Bare Feet or Socks?

To understand how these shoes behave in real daily wear, I tested them both barefoot and with different socks. I was curious to see how much the look, comfort and fit would change, especially with the open lattice structure.

©3DWithUs – Photo: Max Funkner

Bare feet, of course, make these shoes look the coolest, but I tried them with both high socks and low socks as well. I have a few pairs of Union Jack low socks in different designs, and they all work surprisingly well with these shoes.

©3DWithUs – Photo: Max Funkner

I asked my wife to try the white Aero shoes that were delivered in her size. When we tested them, it turned out the pair was slightly larger than her actual foot length. Nevertheless, the shoes still looked very good on her and the overall design suited her well.

Comfort and Fit

At first wear, the shoes feel surprisingly light and flexible. The lattice compresses naturally underfoot, adjusting to pressure points. While they lack a conventional arch, they remain comfortable for light walking and indoor use. I was initially surprised not to see any arch support, but even after stress-testing them for two days in a row at Formnext, I didn’t feel any related discomfort. The soft front section of the shoe absorbs most of the impact, which helps reduce fatigue.

©3DWithUs – Photo: Max Funkner

After a 40-minute session on the cross trainer, I did notice a light imprint on my upper sole through the socks. I suspect that after one or two hours of this kind of training, when the whole body weight is concentrated on the upper sole, I might feel some numbness. This is where I should wear socks with extra padding.

Formnext Real-World Test

To test long-term comfort and durability, I wore the same pair of Flux shoes at the Formnext trade show in Frankfurt. Two full days of walking across multiple exhibition halls turned into an excellent field test. The shoes handled the event surprisingly well: no noticeable deformation, a good grip on polished floors, and consistent cushioning throughout. Honestly, I expected blisters; I got some when I was wearing standard shoes at events a few years ago, but this time it never happened.

©3DWithUs – Photo: Max Funkner

This is also where I tested them with Formnext-branded high socks. High socks are almost inevitable in winter in northern countries to keep the cold out.

Another surprise was the temperature. I expected the open lattice structure to feel cold inside the trade show halls, but no, the temperature at Formnext was ideal, and I didn’t feel cold at all. Outdoors, in wet and cold weather, it is a different story. A five-minute walk from the hotel to the venue was okay as long as every puddle was carefully avoided. Step into one, and yes, the feet will get wet instantly.

Looking forward to trying these shoes again at other trade shows. And by the way, they are a fantastic conversation starter. It worked very well for me.

How PollyFab Shoes Are Made

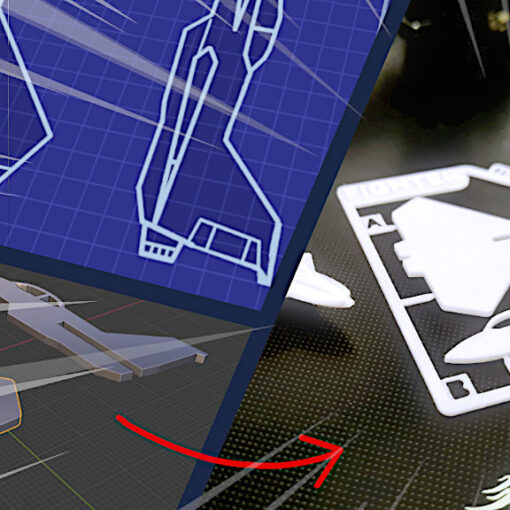

PollyFab’s lattice shoes are produced through advanced additive manufacturing using a custom, bio-based elastomer called ELASTO 1000 BIO, designed for high elasticity, resilience, and long-lasting flexibility. This specially engineered material allows the lattice structure to bend, compress, and rebound with each step, giving the shoes a springy, adaptive feel that would be difficult to achieve with traditional materials.

Rather than stitching or gluing parts together, the entire shoe, sole and upper included, is built as one continuous piece from digital design files. This lets PollyFab create lightweight, breathable cushioning and complex lattice geometry in ways that conventional footwear manufacturing cannot easily replicate. For more details on the technology and philosophy behind the design, see the official PollyFab website.

Conclusion and Pros & Cons

Aero: Official Website

Flux: Official Website

Another reason I enjoy these shoes so much is that they feel like a real glimpse into the future. Wearing fully 3D printed footwear makes me think about how quickly things are progressing. One day soon, we’ll scan our feet, drop a file into a home 3D printer, and produce shoes perfectly tailored to our own geometry. Whether the structure is lattice or something entirely new, the concept of a fully printed, custom-fit shoe feels incredibly close. Shoes like the PollyFab Flux and Aero act as a reminder that this future is not far away; it’s already partially here.

In the past, I looked skeptically at ‘3D printed’ shoes from major brands. Yes, their lattice midsoles are amazing, but the upper is still made with a different, inaccessible technology; it breaks the magic. For me, fully 3D printed footwear carries a completely different meaning. It’s authentic, maker-friendly, and aligned with the spirit of the open, experimental 3D printing community. With fully printed shoes like PollyFab, we’re getting closer to the moment when printing similar shoes at home becomes not only possible, but practical. Files will become more available, scanners will become simpler, and fully printed, customizable footwear will be within reach of anyone with a 3D printer.

Pros:

Lightweight and breathable

Visually striking lattice design

Comfortable for short-term wear and low-impact activity

Cons:

Some may prefer arch support

Not ideal for rough/wet outdoor use

Have questions? Feel free to ask in the comment section below.

For a wider discussion or to share your own 3D printed shoes experience, join us in the forum: