With strong demand for serial production, WASP offers a new solution, offering the possibility for producing small series of objects and allowing fast and cheap product variations with the new customized serial production. Delta WASP 2040 PRODUCTION – offers an automated process for 24h 3D printing with technical materials and an automatic 3D print removal system.

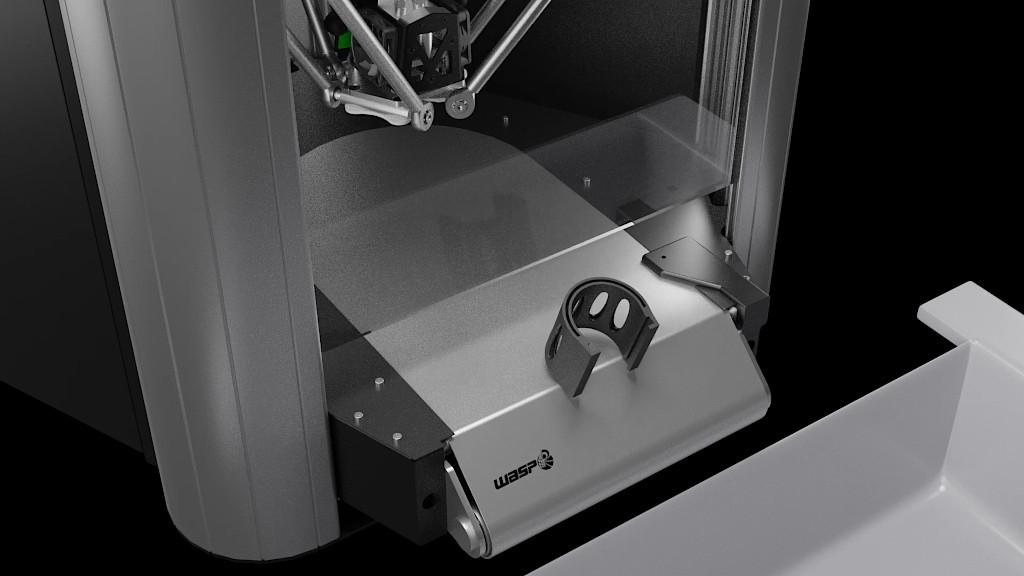

Automatic 3D Print Removal System

Delta WASP 2040 PRODUCTION paves the way to a new concept in production mixing the capacities of additive technology, hence customization, with mass production. Once the printing is finished, the stainless steel belt brings it outwards until it finally detaches from the printing surface. The belt will return into the previous position to start another print. The belt is also divided into different zones with different surface textures and materials in order to allow optimal adhesion.

But wait, that’s not all!

Delta WASP 2040 PRODUCTION – Belt 3D Printer

WASP has solved the most frequently occurring issues with belt equipped 3D printers. Poor flatness, warping, lack of adhesion and vibration of 3D printed parts have been solved by introducing the so-called: “Vacuum System”. In fact, stainless steel, in addition to the possibility of being heated up to 120°C, maintains its flatness and stability during the whole printing process thanks to a pump generating vacuum on the build plate. The pump is then deactivated to allow the belt to move once the printing is finished.

(Image: 3dwasp.com)

Heated Chamber with Dynamic Door

WASP introduces another interesting solution for printing using technical materials such as ABS, PA-CF and TPU, where an air heater brings the chamber temperature up to 70°C, and a dynamic door opening is based on the height of a printed part, in order to reduce the loss of heat inside the chamber.

(Image: 3dwasp.com)

Job Queue Function

A new function called a “job queue” has also been implemented in order to better manage production. This function allows the user to select a number of parts to be printed but also makes it possible to print different objects in sequence.

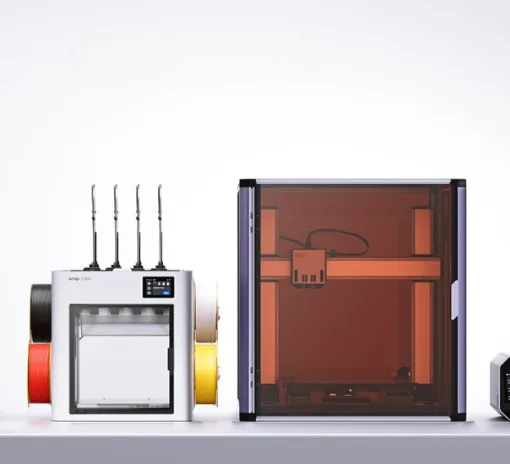

Delta WASP 3D Printers

The new Delta WASP 2040 PRODUCTION is also supported by all the already established innovations seen on the Delta WASP INDUSTRIAL X, such as steel cord belts, dual gear filament driver, auto-calibration system, continuous print mode, Gcode analysis, and an optimized firmware for WIFI remote control. A new paradigm in the industry field is officially formed.

Delta WASP 4070 TECH contributes to the digitization of companies and it is therefore compatible with European funding for technological development.

Source & Links

PREORDER on 3dwasp.com

and more information:

Tel +39 0545 87585

Read More & Compare

Read more about desktop 3D printer builds and processes. Type, volume, FDM or Resin, all to consider. Or jump to the latest 3D printer reviews.

For a comparison with other belt 3D printers please refer to the

detailed belt 3D printers guide.