An innovation-rich year has just seen another remarkable entry – a resin DCLF 3D printer. Rocket 1 by HITRY benefits from a new technology for printing in resin and promises a higher speed and better quality using a new type of resin. Let’s take a look at the campaign, check specifications and take the first glance at this novel technology.

Rocket One and One PRO Specifications

Dimensions: 330x330x790mm

Weight: 15kg

Technology: DCLF

Speed: 100-380 / 100-420 mm/h

Build Volume: 130x82x150mm / 143x89x150mm

Resolution: XY – 0.05 / 0.035mm, Z – 0.001mm

Layer Thickness: 0.025mm – 0.2mm

Materials: HITRY 8 different types of resin.

(more info below)

Innovative DCLF

DCLF – Digital Continuous Liquid Forming. As the patent for this technology is still pending, HITRY are reluctant to reveal more about it. In the comment section, it was possible to fish out that the technology principle is similar to DLP without DMD chips.

HITRY commented:

“It is not DLP, SLA, LCD, but a new projection technology, similar to DLP technology, but DCLF technology uses other image display technology chip to replace the DMD chip, so that the price is greatly reduced, and the accuracy is greatly improved.”

(Image: HITRY)

More information about the technology should be available next year.

According to the campaign, this technology allowed to dramatically increase the speed of resin 3D printing, up to 420mm/h, as well as the quality of prints.

– No need for replacement parts. Another significant bonus is that no replaceable screen or release films are required. Usually, an LCD screen’s lifespan is 3000h hours if used correctly. While changing the LCD screen is not required often, then FEP release films are changed frequently.

– Uses. A 3D printer with this technology can be used for the same purposes as any traditional resin 3D printer in the automotive industry, making miniatures, industrial applications, jewelry, dental, etc.

Rocket 1 Resin 3D Printer

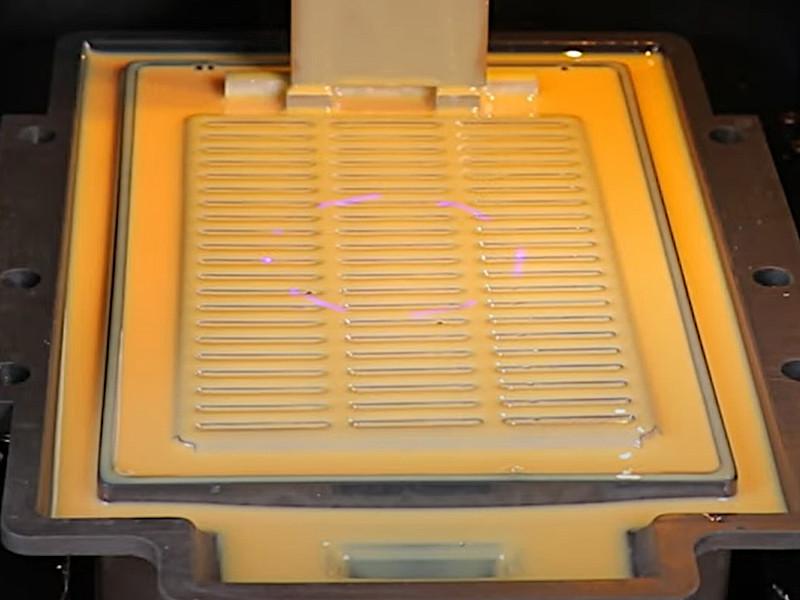

Significantly taller than traditional resin desktop 3D printers, Rocket One has a deep resin and filling liquid tank, along with a build platform and DCLF projector at the top of the enclosed chamber.

– Filling Liquid. Another innovation by HITRY. The first impression of a full tank (3.7kg of resin) was that it won’t be practical to use such a big amount of resin for the purpose of one print. Then the effect of a reusable filling liquid made it clear that it was possible to have only 300g of resin for a machine to print. Another video in Rocket 1 VIP group on Facebook shows how to use a big volume syringe to separate the resin leftovers in order to clear the filling liquid making it ready to be used again.

Resin poured into the tank with filling liquid

MP4: HITRY

– Build plate. Unusual, stainless steel build plate that submerges in the tank in the process. Easy to operate and maintain.

– Top-Down 3D Printing. If a traditional LCD or DLP 3D printer pulls photopolymerized prints up, then in this process, the prints go down instead until the finished object is pulled out.

Superoxide Resin

To optimize resin qualities, HITRY developed a special superoxide resin. The total of 8 different proprietary resins include: Rapid-leveled Resin, Tough Resin, Super Transparent Resin, Superoxide Resin, Ultra-high Temperature Resistant Resin, Flexible Resin, Casting Resin, Dental Resin.

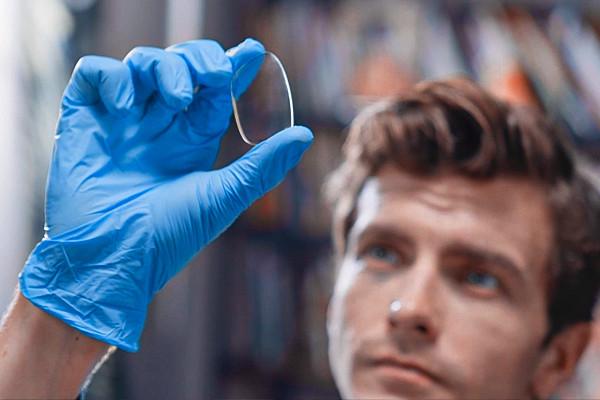

– Flexible and Transparent 3D Printing. As there are no gravity or pulling forces involved, such printing technique allows achieving a new level of flexibility and transparency.

The best temperature to operate with such resins is between 20 and 30°C, for an optimized flow.

It is not clear if this DLCF-empowered technology will be able to operate with the 3rd party resins, and more testing is required. Also, shipment from Shenzhen, China, makes branded resin pricier due to the shipment costs and customs duty, which seems to be the only drawback.

(Image: HiTry)

Rocket 1 Campaign – Too Good to Be True?

At the moment of writing this post, the campaign accumulated more than $600,000. As the technology is new, a lot of questions are being asked and answered. HITRY does a great job here. Some backers demanded to see a review by an independent reviewer, and the company confirmed that a sample machine has been sent to Uncle Jessy for the review. Uncle Jessy is a prominent YouTuber and a co-creator of the ResinLapse, who has great experience in reviewing resin 3D printers on his channel. We can only wait for his review to come out in the coming days or weeks.

Conclusion

HITRY’s R&D team answers all questions, understandably avoiding some sensitive questions about the technology until the patents are granted. We can’t wait to see this technology in the hands of 3D printing community members. Their experience will help to determine if this technology is practical for desktop 3D printing at home. Nevertheless, the idea is awesome, and we wish HITRY to fulfill their project and launch the new page in resin 3D printing history with the blast.

Campaign page: Kickstarter

Disclaimer: Crowdfunding campaigns – before taking part in any campaign as a backer, please read T&Cs.

Read More: Best Resin 3D Printers

Here you will find the best resin 3D printers. This type of machine is widely used by professionals and hobbyists. Let’s briefly look at the differences between SLA, DLP, and LCD processes, the latest innovations, and see where such machines are used. As the technology evolves and more machines come out onto the market this guide is constantly edited.

Filling fluid is definitly not an innovation, many top-down printers do use this trick ie https://milkshake3d.com/

Same about the patent claims, I’m not an expert and i will probably state the f…g obvious but if it is a utility patent application you can definitly find them online, I’m not sure about a provisional patent but there is no reason why they wouldn’t available as well. So chances are that they don’t want to disclose the etails juste because there is no innovation, just painted the toy in pink and called it a “revolution” !