The Sculpto PRO2 is a 3D printer from the Danish 3D printer manufacturer Sculpto that stands out in the desktop 3D printer market for several unique reasons. The first thing you’ll notice when looking at this printer is the unusual size and shape of the build platform and the hot end gantry. The Sculpto PRO2 is a polar 3D printer that completely lacks an interface or any buttons other than a single power switch. In this article, we will review the polar coordinate system, mobile app based slicer software, and check the printer hardware.

I purchased this printer from a retail store, which is equally unusual for a 3D printer. While several electronics retail stores such as MicroCenter and Fry’s Electronics have sold printers in the past, the Sculpto PRO2 is unusual in that it is sold alongside common crafting supplies and targeted at novice hobbyists.

Sculpto PRO2 Specifications:

Resolution: .15mm to .35mm

Build Volume: ⌀200 mm x 250 mm

Material: 1.75mm PLA Filament

Connectivity: Wi-Fi

Hot End: Genuine e3D V6 and .4mm Nozzle

TMC2208-LA Silent Stepper Motors

The build platform that spins. (MP4: Andrew Sink)

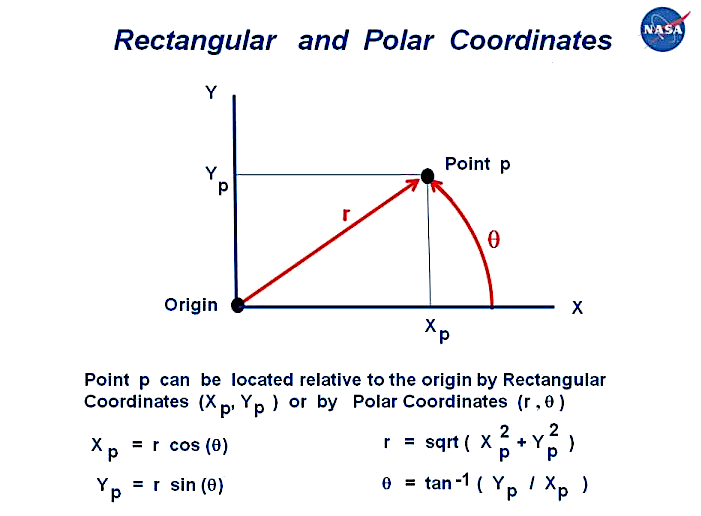

Polar 3D Printer / Polar Coordinate System

Unlike a traditional 3D printer that utilizes a build platform that is either stationary or translates along a single axis, the entire build platform on this machine rotates while a swinging arm controls the position of the hot end. This is a unique system known as a polar 3D printer, as opposed to the more common Cartesian-based machines that use an x, y, and z coordinate to determine toolpathing.

(Image: NASA)

This printer uses polar coordinates for movement: r, theta, and z. The r value represents the radius value (how far from the center of the build platform), the theta value represents the angle from the midplane of the build platform, and the z value represents the height of the nozzle. By using this unique coordinate system, the machine is able to print by moving the nozzle in relation to the center of the build platform to control the r value while also moving the build platform itself, which controls the theta value.

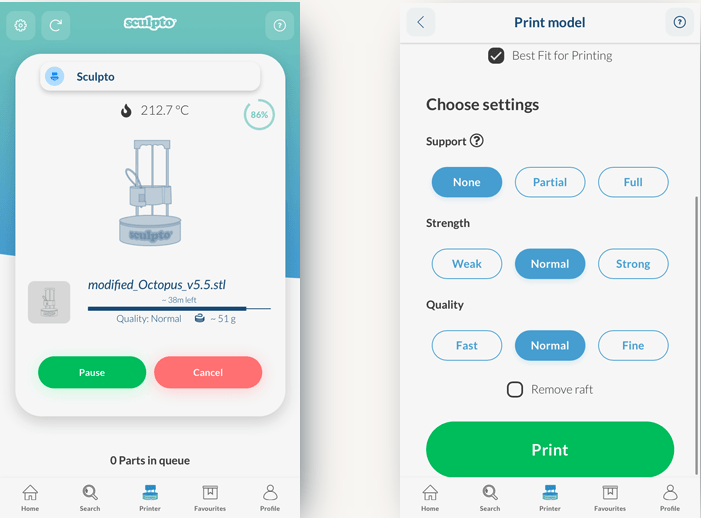

Phone-Based Slicing App

Just like the unique polar coordinate kinematic system used by the Sculpto PRO2, the software provides an equally unique printing experience. The PRO2 has no interface whatsoever, only a single on/off switch which is used for turning the machine on and off. Selecting, slicing, and sending the file to the printer are all accomplished through a phone app, downloadable through the Apple App Store and the Google Play Store.

This app gives basic control over print settings (Support, Strength, and Quality), and sends the file to the printer over Wi-Fi. Unfortunately, without this app and access to uninterrupted Wi-Fi, the printer is not usable. For a beginner who isn’t used to the slicing and print preparation process, this may not be a big deal, but it could certainly be a sticking point for anyone interested in changing the more advanced settings of the print or seeking more control over the printer.

(Photo: Andrew Sink)

Hot End and Extruder Mechanism

The Sculpto PRO2 ships with a genuine e3D V6 hot end and nozzle (Amazon affiliate link); it also includes a silicone sock for the heater block. The PRO2 also includes a holographic sticker from e3D on the back of the printer to confirm the authenticity of the components. For a home user with limited experience in 3D printing, this probably won’t have the same impact as it would for someone who has used 3D printers in the past.

The extruder is a Bowden system that feeds filament through a tube to the hot end from the back of the printer. The extruder module is located inside the body of the machine, with no ability to adjust tension or flow. While this wasn’t a problem for me while testing the machine, it’s possible that a filament jam would prove difficult to clear without access to the idler arm.

(Photo: Andrew Sink)

Flexible Magnetic Build Platform

The rotating build platform on the PRO2 is made of three layered components: a rigid layer on the bottom, a magnetic surface, and a removable flexible sheet that can be peeled off without removing the platform from the printer. The platform stack is held in place with three magnets that allow the user to self-locate the platform by placing it on the printer and rotating it until it locks into place. When the print is finished, the top flexible sheet of the build platform can be removed and bent so the part pops off. This is a much simpler process for part removal than having to remove the entire build platform after each print, and the flexible nature of the sheet means the part pops off without a scraper or any hand tools.

(Photo: Andrew Sink)

Printer Hardware

The Sculpto uses a proprietary controller board that is located in the base of the printer. The PRO2 uses four TMC2208-LA silent stepper drivers which allow the printer to run silently without any noise being generated from the stepper motors. The PRO2 advertises a noise level of 45 dB while printing, which puts it comfortably within the range you would expect from a consumer appliance.

Sculpto PRO2 Print Quality

The overall print quality of the PRO2 was about what I would expect from a consumer printer in the sub-$300 price range, with very little ringing, stringing, or any other major visible defects present on the benchmark parts that were printed. Printing the Benchy as a test part resulted in a decent looking part that could easily be compared to a print from a standard Cartesian 3D printer.

While the rotating build platform was level on this machine, it’s clear that it would be difficult to compensate for an unlevel platform or a platform with any deformation during the printing process due to the lack of an interface. I didn’t run into any leveling problems during my test prints, but I can imagine it would be a frustrating experience for anyone unable to compensate for variable height changes.

Conclusion

The Sculpto is a very unique and interesting 3D printer, but it lacks many of the basic features required to succeed in the home and hobbyist market. While the phone app allows for a simple and streamlined part preparation process, the lack of an interface could be frustrating for anyone who is trying to make adjustments during printing. In addition, there is always the potential that the app will no longer be updated by Sculpto, which would leave the printer in a permanently idle state. Overall, the Sculpto PRO2 is an interesting machine that would be of interest to anyone who wants to experiment with a polar kinematic system, but beginners may need to look elsewhere for a reliable first printer.

- Sculpto Official Website

- Read more: FDM Desktop 3D Printer Types

- Sculpto PRO2 3D Printer on Amazon (affiliate link)

Read More & Compare

Read more about desktop 3D printer builds and processes. Type, volume, FDM or Resin, all to consider. Or jump to the latest 3D printer reviews.

For a comparison with other FDM 3D printers please refer to the

detailed budget FDM 3D printers guide.

I own 6 of these now in expert mode and prefer them still over my Anycubic