3DQue has released Quinly, a 3D printing automation package that allows users to convert Prusa MK3, Creality Ender 3, and their clones into the automated machines that can produce parts after parts without any operator supervision required.

This guide covers:

- Kit for Original Prusa

- Tilt Frame

- Quinly for Ender 3 and Compatible Brands

- Quinly for Ultimaker S5

- VAAPR Print Bed

- 3D Printing Automation Software

- How to Buy

After the runaway success of the Creality 3DPrintMill campaign which raised nearly $1.4 million dollars on Kickstarter, the interest in machines capable of serial production, like belt 3D printers and other, has never been higher. The market has made clear that there is an ever-growing interest in low-cost machines for this application, and manufacturers are coming up with many unique and creative ways to fulfill this need.

Automate Your Original Prusa MK3

A full automation conversion solution that includes hardware, software, and a proprietary build platform material that enables you to use your Prusa for continuous high-volume printing.

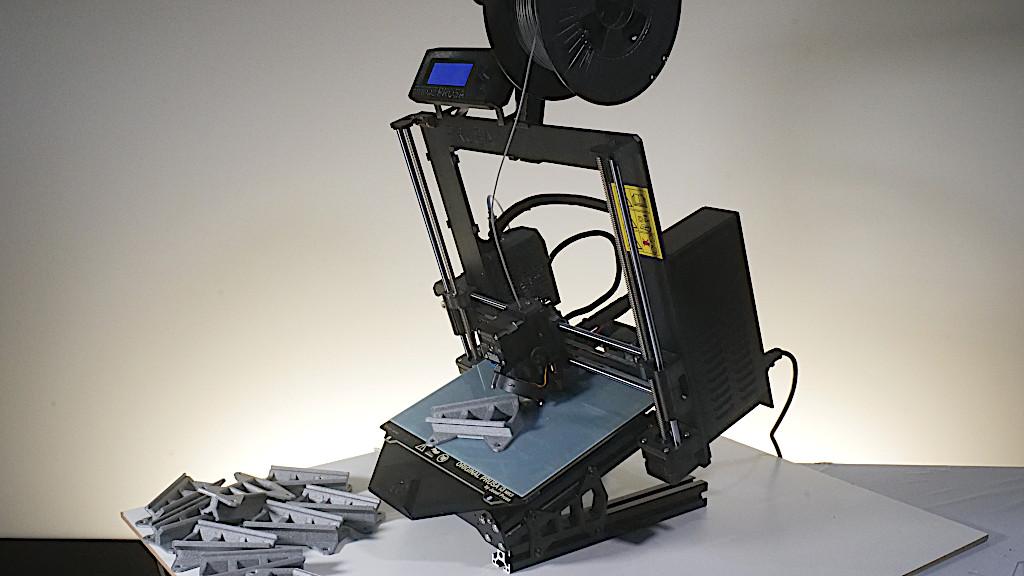

The Quinly for Prusa is unique as a product in that it builds on the existing hardware platform of the Prusa MK3 series of 3D printers. The Original Prusa i3 MK3 3D printers are widely hailed as reliable, workhorse machines, but they share the similarity of requiring an operator to start and stop prints with the rest of the 3D printers available in the market. By creating an automation solution that builds on the existing reliability of the sensor-filled MK3 platform, 3DQue has filled a niche in the market for anyone interested in serial production who doesn’t want to purchase an additional dedicated machine.

(Image: 3DQue)

Tilt Frame

The Quinly for Prusa package includes a tilt frame that angles the printer with the bed facing downwards, allowing 3D printed parts to be knocked off and fed into a container without requiring an operator to manually remove them. Unlike a belt-driven system that allows the print bed to also act as a conveyor belt to move parts away from the print area, the tilt frame creates a natural angle for the part to remove itself from the print area.

(Image: 3DQue)

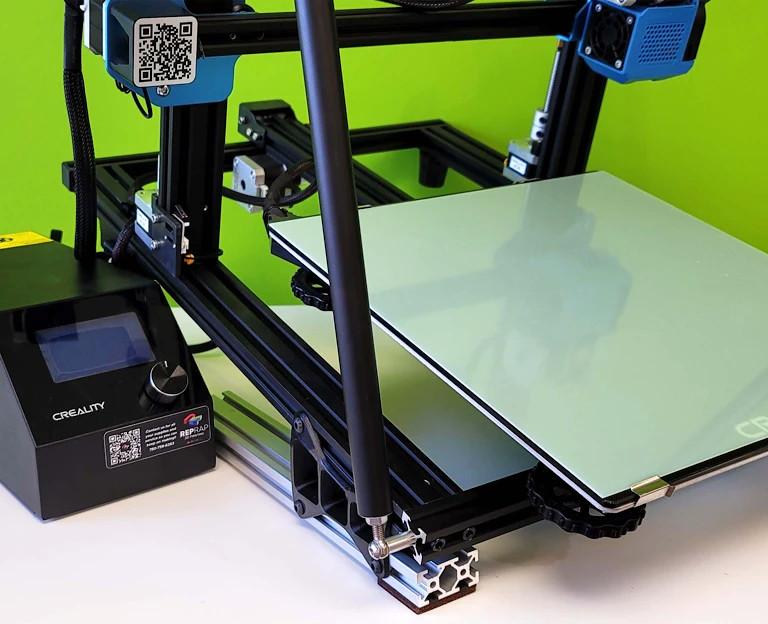

Automate Your Creality Ender 3

This tilt frame is similar to 3DQue’s previous endeavor, the Quinly for Ender 3. The Ender 3 package is available in both a fully assembled and DIY print-it-yourself kit form, available for $229 and $129, respectively. This tilt frame is a unique way to allow the printer to free parts from the bed after printing, but it’s not the only feature of the Quinly system that enables this sort of production.

Automation System for Ender 3 Clones and other 3D Printers

After providing the Quinly automation system for some of the most popular 3D printers, 3DQue started to work further to make the system available for implementation on other 3D printers. Ender 3 clones are the next in line. Quinly system became compatible with the following printers:

- Voxelab Aquila

- Creality CR-10

- Creality CR-6 SE

- Sidewinder (beta testing)

- Prusa Bear (beta testing)

(Image: 3DQue)

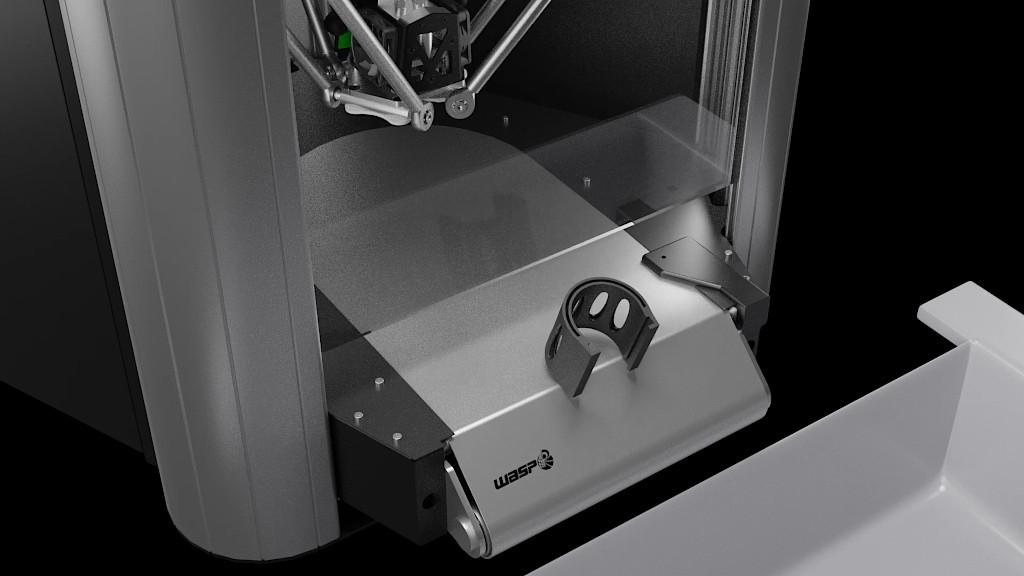

Quinly for Ultimaker S5

Quinly has been developing automated systems for lower-end 3D printers, and now they have such system for a higher-end machine. Ultimaker S5 is a professional-grade 3D printer with a heated bed and enclosed chamber. In the YouTube video below, you can see how the preinstalled folded arm gets activated and pushes the finished and cooled part off the Ultimaker’s glass bed.

VAAPR Print Bed

The Quinly for Prusa system, like the Quinly for Ender system, uses 3DQue’s proprietary VAAPR Print Bed technology. The VAAPR print bed enables a high level of adhesion during printing when the bed is heated, so parts don’t slip off and are held rigid. After cooling, the VAAPR Print Bed releases the object so the X-axis gantry can nudge the part off the print bed without damaging the part, printer, or platform. This specially designed print bed aims to solve a common problem present in automating FDM 3D printing systems; too much adhesion and the part can’t be removed from the bed, not enough and the part delaminates during printing and an operator is required to reset the printer.

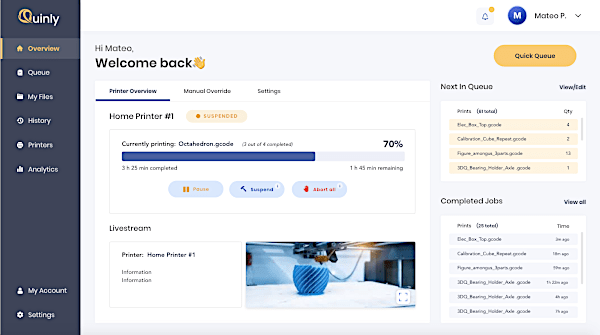

(Screenshot: Quinly Software)

Quinly 3D Printing Automation Software

The Quinly automation solution uses 3DQue’s software for scheduling, queueing, and keeping track of completed jobs. This software is compatible with both the Ender and Prusa solutions, and is also compatible with common modifications such as direct drive extruders, BLTouch systems, and more. By combining intelligent queueing software, the VAAPR Print Bed, and the specially designed tilt bracket, the Quinly for Prusa system can print using most common thermoplastics including PLA, ASA, ABS, Polycarbonate, and more without requiring operator assistance between prints.

Affiliate Links:

Original Prusa i3 MK3

On Prusa3D

Creality Ender 3

On Amazon

How to Buy

The Quinly for Prusa 3D printing automation solution is currently available for sale on the 3DQue site at the introductory price of $349.99. This solution includes the tilt bracket, VAAPR print bed, LCD relocator bracket, and all additional software and documentation required to get started. 3DQue has also added a materials page on their site that documents the various types and brands of filament that have been tested and qualified for the Quinly platform. In addition to the Quinly for Prusa kit, 3DQue also offers the Quinly for Ender 3 in both fully assembled and kit form.

For additional information, visit the 3DQue Site.