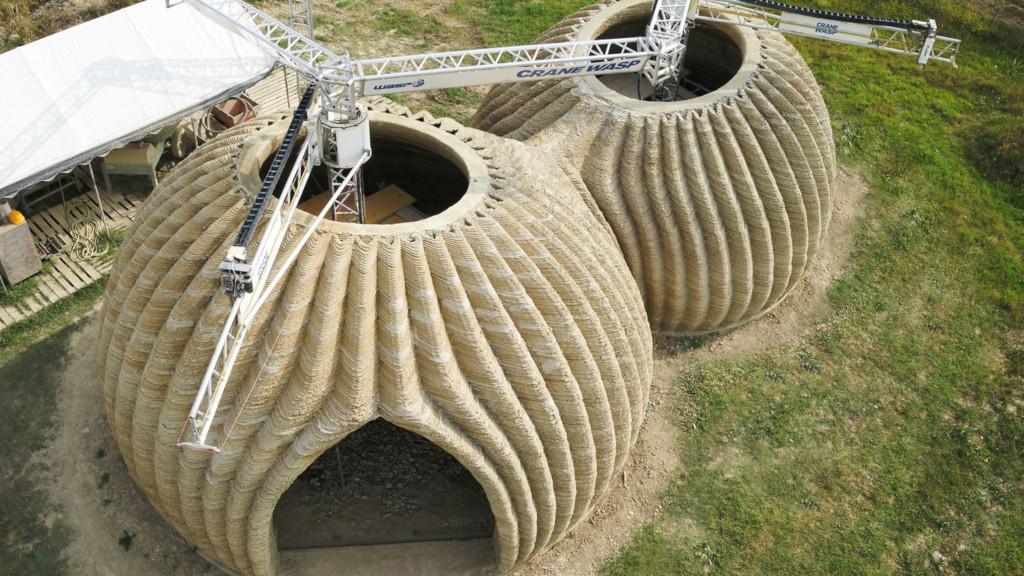

The topic of 3D printing buildings has come up frequently in the past few years, but few companies have manifested as interesting a concept as the Italian industrial 3D printer manufacturer WASP (World’s Advanced Saving Project) with their Crane WASP 3D printer.

Designed through a collaboration between WASP and MC A (Mario Cucinella Architects), the Crane WASP utilizes a modular platform to collaboratively build a structure based on application-specific needs. WASP has created 3D printers designed for building structures in the past, including the Big Delta WASP 12 meters which was designed to create monolithic structures.

(Image: WASP)

TECLA – Technology and Clay

The latest achievement from the Crane WASP is the TECLA structure (a portmanteau of technology and clay), which was printed in Massa Lombarda, Italy using reusable material that was sourced from local soil. The TECLA was designed to provide a new model of housing whereby buildings are created with reusable and recyclable materials that can be sourced locally. This is an accomplishment worth noting as it reduces the need for material to be imported or transported during the construction process, allowing structures to be built in remote locations using only the Crane WASP.

(Image: WASP)

Collaboration

Creating a structure like the TECLA is an accomplishment that requires the collaboration of multiple partners to succeed. Milan-based engineering consultants Milan Ingegneria assisted in optimizing the dimensions and geometry for an additive process, which allowed for a self-supporting structure that could be built rapidly and was optimized through software and design.

(Photo: WASP)

TECLA Structure

WASP has reported that this optimized shape took 200 hours to print, 350 layers of material, a total of 60 cubic meters of locally sourced material, and used an average power consumption of less than 6 kW.

Building Timelapse – Crane WASP in Action

WASP has also created a fascinating video showing a timelapse of the construction process and showing the similarities between their process and the natural building habits of potter wasps. The video shows highlights from the construction process including the mixing of the building material and the kinematics of the gantry system that deposits each layer.

The video also features many close-up shots of the Crane WASP which can give the viewer a better understanding of how a 3D printed structure is made. The overall shape of the TECLA structure is roughly self-supporting, so no additional materials are required to support the walls as they are being deposited. In addition, a lattice structure is printed inside the walls similar to the way a 3D printed part uses an infill pattern to reduce the amount of material used during the fabrication process.

The Future of Construction

By creating a 3D printed structure using a specialized machine and locally sourced materials, WASP has demonstrated that this style of construction is no longer simply an idea, but a practical reality that can be produced and reproduced. WASP has also introduced the Maker Economy Start Kit, which contains the tools and equipment required for users to build a structure themselves using the technology developed for the Crane WASP. This kit allows for the construction of structures, vegetable gardens, and more using the same digital fabrication principles as the Crane WASP.

- For more information, please visit WASP’s site to learn more.

- Read More: 3D Printed House GAIA

- Read More: Delta WASP 2040 Review

Read More: Concrete 3D Printing

3D printing concrete furniture may seem like a futuristic concept, but it may be coming soon to a living room near you thanks to …