Uniformation GK3 Pro is a machine that doesn’t just want to compete in the resin printing space — it wants to redefine expectations. With its sleek industrial design, integrated enclosure, and plug-and-play setup, the GK3 Pro positions itself as a serious tool for creators who demand both performance and polish. But in a market crowded with budget options and premium giants, can it carve out its own niche?

We’ll examine its features and printing capabilities in this review and, as always, list the pros and cons.

Table of Contents (Jump to a Section)

- Uniformation GK3 Pro Specifications

- What’s in the Box

- Setup and Calibration

- Touchscreen

- Design Features

- Smart Resin Feed System

- Software – Uniformation Slicer

- Test Printing Results

- YouTube Video

- Compare to Other 3D Printers

- Conclusion and Pros & Cons

Where to Buy Uniformation GK3 Pro

Price: $719.99 – $899.99

Compare the Prices & Bundles:

Official Store | Amazon

Uniformation GK3 Pro Specifications

- Display Resolution: 16K monochrome LCD for ultra-fine detail

- Build Volume: 211 × 118 × 240 mm — suitable for medium-to-large prints

- Light Source: 385 nm COB UV light with Fresnel collimator lens for sharper curing and reduced scattering

- Film Type: CPFA film (vs. nFEP in GK3) for better durability and light transmission

- Polariser: Dyed polariser improves light transmission by 12% and contrast by 21%

- Printing Technology: Resin

- Print Volume: 211 × 118 × 240 mm

- Bed Leveling: Automatic print bed levelling

- Drive System: Ball-screw driven Z-axis for stability and precision

- Assembly: Fully assembled — plug-and-play setup

- Heating System: Intelligent resin heating with preheat function; reaches 0–25 °C in ~35 minutes

- Smart Resin Feeding: Monitors resin levels and ensures a continuous supply

- Monitoring: Built-in camera for real-time print monitoring and time-lapse recording

- Touchscreen: 90° rotating touch display for ergonomic access

- App Support: Uniformation Smart App for remote control and monitoring

- Connectivity: USB, Wi-Fi, LAN — supports Windows 7+

- Quick-Release Build Platform: Simplifies post-processing

- Resin Drip Hanger: Minimizes mess during print removal

- High-Temperature Screen: Withstands up to 100 °C, enhancing durability

Please find the GK3 vs GK3 Pro comparison, up-to-date specifications, official specifications, and packing list on the official product page.

What’s in the Box

The Uniformation GK3 Pro comes fully assembled and includes everything needed to get started: the printer itself, power cable, build platform, and a resin vat with a pre-installed CPFA film. Inside the accessory kit you’ll find Allen keys, a scraper for removing prints, funnels and filters for resin handling, plus gloves and masks for safety. A USB drive with test files and firmware is also provided, along with the user manual, quick start guide, and slicer software (or download link). Depending on the bundle, you may also receive a Wi-Fi antenna, spare screws, and an additional CPFA film.

©3DWithUs – Photo: Phil Macey

Setup and Calibration

So, the Uniformation GK3 Pro shows up fully assembled, which is already a win. No messing around with bolts or brackets—just unbox it, plug it in, and you’re nearly there.

First things first, I placed it on a flat, stable surface with good ventilation. The Wi-Fi antenna needed a quick twist to install, and then I connected the power cable and flipped the switch on the back. The touchscreen fired up right away, and the interface was clean and responsive.

The resin vat comes pre-installed with a CPFA film, and the build plate is already mounted. I gave everything a once-over to make sure it was snug and level. If you want to double-check the leveling, there’s a guided calibration tool right on the screen—it’s quick and intuitive.

Next, I popped in the USB drive to access the test files and firmware. I connected the printer to Wi-Fi through the touchscreen, then downloaded the Uniformation slicer and the Smart App. If there’s a firmware update, it’ll prompt you—definitely worth doing before your first print.

For resin setup, I poured it into the vat using the included funnel and filter. The GK3 Pro has smart resin level detection and auto-feeding if you’re using their cartridges, which is a nice touch. I also tested the resin heating feature—it brought the resin up to temp in about 30–35 minutes, which is great if your workspace runs cold.

You can also enable the built-in camera for time-lapses or remote monitoring, and the rotating touchscreen makes it easy to adjust depending on your setup.

Once everything was ready, I loaded a test file from the USB and hit print. The machine handled the rest—quiet, smooth, and no surprises.

Touchscreen

The GK3 Pro’s touchscreen is one of those small upgrades that makes a big difference. It’s mounted on a 90° rotatable arm, so whether you’re standing, sitting, or working around a cluttered bench, you can tilt it into a comfortable viewing angle. That’s especially handy when you’re swapping resin or checking print progress mid-job.

The interface itself is clean and snappy. You’ve got large, clearly labeled icons for key functions—resin heating, print monitoring, calibration, and file selection. It boots quickly and doesn’t lag, which is a relief compared to some of the clunky UIs I’ve dealt with on other machines.

Calibration

The printer comes with hands-free automatic levelling features, so you can print straight out of the box with built-in sensors, but it also provides a detailed guide if re-levelling is needed.

©3DWithUs – Photo: Phil Macey

Design Features

One of the standout mechanical features on the GK3 Pro is its linear rail system on the Z-axis, paired with a ball screw drive. That combo gives the printer a serious edge when it comes to layer consistency and vertical stability—especially important when you’re pushing ultra-fine detail with a 16K screen.

Compared to cheaper resin printers that rely on single rods or less rigid guides, this setup virtually eliminates Z-wobble, even on taller prints. You get clean layer transitions, sharper edges, and fewer artifacts—especially noticeable on miniatures, dental models, or anything with tight tolerances.

The ball screw mechanism adds another layer of precision. It’s smoother and more accurate than lead screws, which means less backlash and better repeatability across multiple prints. That’s a big deal if you’re running batches or prototyping parts that need to fit together.

©3DWithUs – Photo: Phil Macey

From a maintenance standpoint, the rails are low-friction and durable, so you’re not constantly re-lubing or adjusting tension. And because the GK3 Pro is fully enclosed, dust and resin fumes aren’t constantly settling on the motion system, which helps keep things clean and consistent over time.

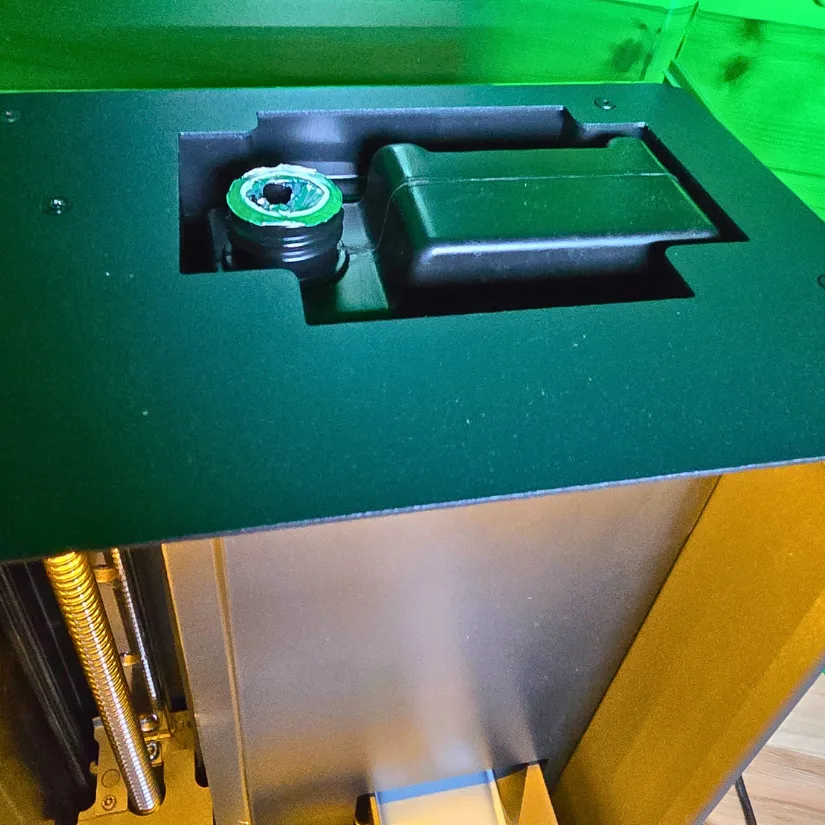

Smart Resin Feed System

The GK3 Pro takes a lot of the hassle out of resin handling with its smart resin feed system. Instead of manually topping up the vat mid-print, the printer can automatically draw resin from a connected bottle, keeping the level consistent throughout the job. That’s a big deal if you’re running large prints or back-to-back batches—you don’t have to babysit the machine or risk a failed print due to low resin.

It uses Uniformation’s proprietary resin bottles, which plug directly into the feed port. The system monitors resin levels in real time, and when it senses a drop, it triggers the feed to top things up. It’s a closed-loop setup, so you’re not dealing with open bottles or messy pours once the print is underway.

There’s also a resin heating function built into the system. If your workspace runs cold, you can preheat the resin to around 25 °C before printing, which helps with flow and curing consistency—especially for thicker or specialty resins.

Overall, it’s a clean, efficient system that reduces mess, saves time, and adds a layer of reliability to longer print jobs. If you’re used to manually pouring and filtering resin every few hours, this feels like a serious upgrade.

©3DWithUs – Photo: Phil Macey

Print Bed Drain Holder

The print bed drain holder on the Uniformation GK3 Pro is a simple but thoughtful feature designed to make resin cleanup easier and cleaner. After a print, you can place the plate into the holder at an angle, allowing excess resin to drain back into the resin vat. It’s especially useful when switching resins or prepping for film replacement—less mess, less waste, and no awkward balancing acts. Just another example of Uniformation streamlining the post-processing workflow.

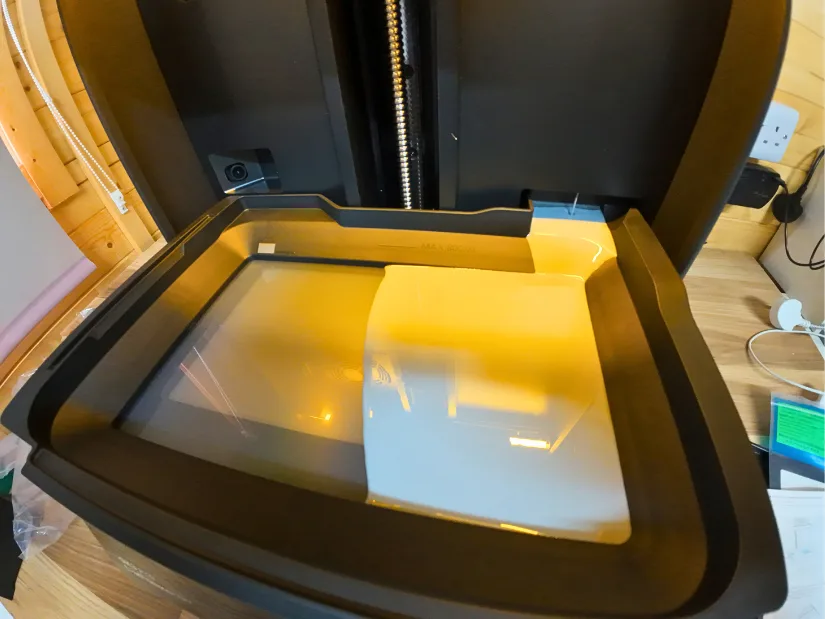

Air Filtration and VAT Cover

The Uniformation GK3 Pro includes a built-in air filtration system designed to reduce resin odors and airborne particles during printing. Housed within the enclosed chamber, it uses an activated carbon filter to help absorb volatile organic compounds (VOCs), making the workspace safer and more pleasant—especially in enclosed or shared environments. It’s a thoughtful touch that supports cleaner, more user-friendly resin printing.

©3DWithUs – Photo: Phil Macey

The GK3 Pro’s vat cover helps protect the resin from dust and light exposure when the printer’s not in use.

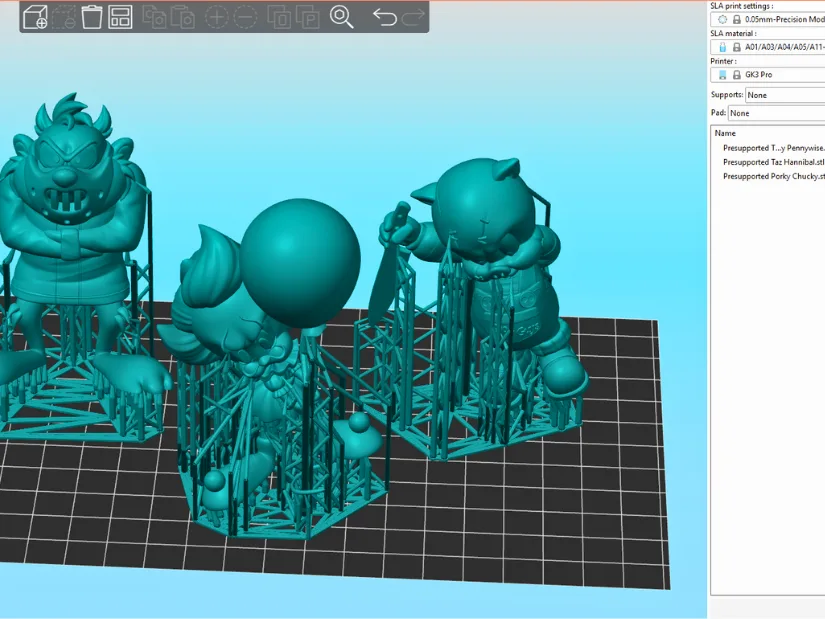

Software – Uniformation Slicer

The Uniformation Slicer is built on PrusaSlicer, but it’s been customized specifically for Uniformation’s resin printers like the GK3 Pro. It comes with pre-tuned profiles for their resin types and hardware, so you’re not starting from scratch. I found the interface clean and familiar, especially if you’ve used PrusaSlicer before, but with added control over things like support pad thickness, lift speeds, and exposure settings.

It’s available for Windows and macOS, and integrates smoothly with the printer—file transfers are quick, and everything just works. For me, it’s a solid slicer that balances flexibility with ease of use, and it’s nice to see a manufacturer actually invest in software that complements their hardware.

Test Printing Results

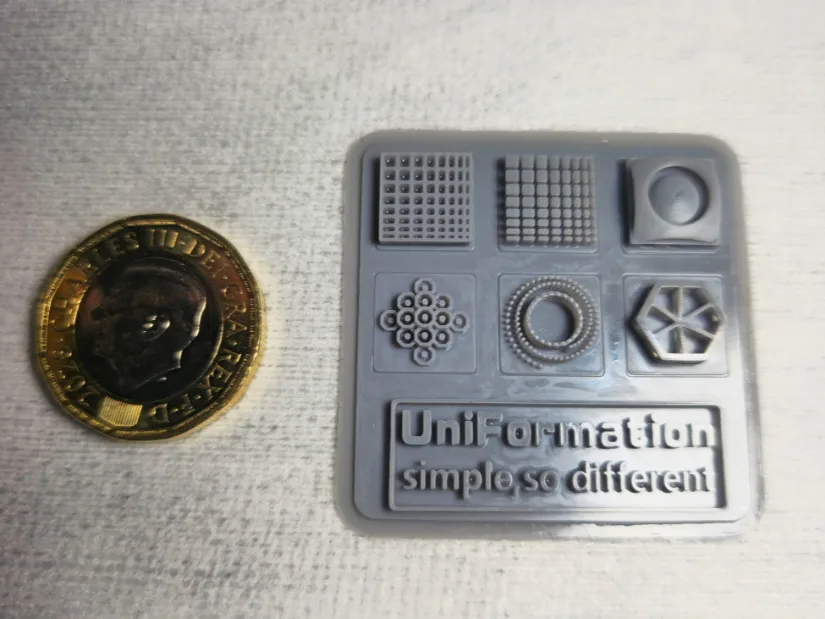

Model Test Print 1 – Uniformation Test Card

For my first test print, I used the default settings from the Uniformation slicer at 0.05 mm precision mode and ran the Uniformation test card found on the USB drive.

©3DWithUs – Print and Photo: Phil Macey

As shown in the image below, the lettering and geometric features came out crisp and well-defined, and the coin provides a clear sense of scale relative to the printer’s resolution.

Model Test Print 2 – Oni Mask

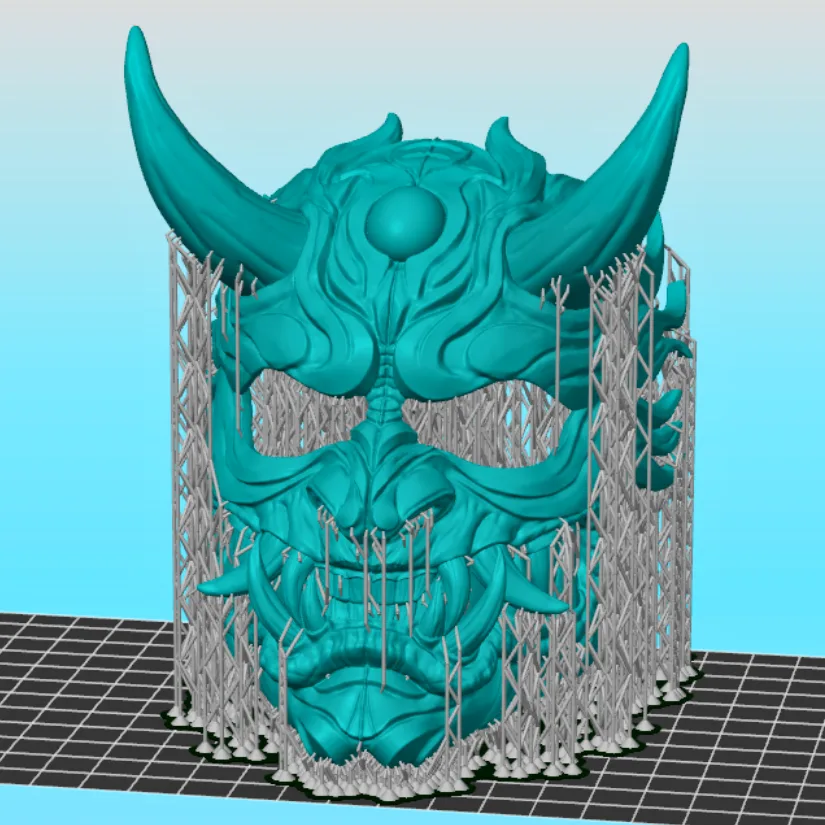

For my second test print, I wanted to push the GK3 Pro a bit further—so I loaded up an Oni mask STL file from STLFLIX to see how it handled more complex geometry and surface detail. I used the same basic slicer settings from the Uniformation Slicer, just to keep things consistent.

©3DWithUs – Print and Photo: Phil Macey

The results were impressive: crisp edges, smooth contours, and no visible layer shifts. It’s a great showcase for how well the printer handles organic shapes and fine textures, even without dialing in custom exposure settings, using the beautiful red clear resin from Sunlu.

Model Test Print 3 – Looney Tunes Diorama

For my third print I decided to print these amazing Looney Toon models from Nostalgic 3D Models on Patreon and created an awesome Halloween backdrop for our home mantelpiece.

©3DWithUs – Print and Photo: Phil Macey

Once again, using the Uniformation slicer and the precision settings at 0.05 mm and using the supplied grey resin from Uniformation, I decided to also use the auto resin feed system.

YouTube Video

To see the Uniformation GK3 Pro in action, including tests and setup, check out the hands-on video walkthrough on my YouTube channel:

Hopefully, the video helps you decide whether this machine deserves a spot on your 3D printing workbench.

Compare Uniformation GK3 Pro to Other 3D Printers

Compare to the similar volume resin 3D printers in the same price range.

Uniformation GK3 Pro is a large-volume resin 3D printer. In this category, both in price and build volume, its closest competitors include the Elegoo Saturn 4 Ultra, Nova3D Whale4, and PioCreat HALOT-X1. These machines all target users who want bigger print capacity, faster workflows, and higher resolution screens. The GK3 Pro sets itself apart with features like the smart resin auto-feed system, integrated resin heating, and a fully enclosed design, which are not always present at this size and price point.

Have questions? Feel free to ask in the comment section below.

For a wider discussion or to share your own Uniformation GK3 prints, join us in the forum:

Conclusion and Pros & Cons

Compare the Prices & Bundles:

Official Store | Amazon

Uniformation GK3 Pro Review

Review Summary

After spending time with the Uniformation GK3 Pro, I can confidently say it’s one of the most thoughtfully engineered resin printers I’ve worked with. From the moment it came out of the box—fully assembled and ready to go—it was clear this machine was built with user experience in mind. The rotatable touchscreen is a standout feature, making navigation and control effortless no matter how your workspace is set up. The smart resin feed system, paired with automatic level sensing and heating, takes a lot of the manual hassle out of resin management, especially during longer prints or colder conditions. And the Z-axis linear rail system, backed by a ball screw drive, delivers the kind of vertical stability that really shows in the final results—no wobble, no layer shifts, just clean, consistent detail.

To put it through its paces, I started with the Uniformation test card found on the USB drive. Using the default slicer settings, the print came out sharp and well-defined—the lettering and geometric shapes were crisp, and the coin next to it gave a clear sense of scale and resolution. For the second test, I loaded up an Oni mask STL to challenge the printer with more organic geometry and surface texture. Again, the GK3 Pro handled it beautifully, preserving fine contours and delivering smooth transitions without any artifacts. Finally, I printed a Looney Tunes-themed model to see how it coped with stylized detail and playful proportions. The results were spot-on—clean edges, vibrant character definition, and no loss of fidelity across the build plate.

Spec-wise, the GK3 Pro is stacked: it features a 10.3″ 16K mono LCD screen with a resolution of 15360 × 6400, offering an XY resolution of 16 microns. The build volume sits at a generous 228 × 128 × 245 mm, and the machine supports Wi-Fi, LAN, and USB connectivity. The enclosed design, built-in air filtration, and CPFA film on the vat all contribute to a cleaner, safer, and more reliable printing environment. And with Uniformation’s slicer—based on PrusaSlicer but tailored for their hardware—you get a streamlined workflow with plenty of control over supports, exposure, and lift speeds.

In the end, the GK3 Pro feels like a resin printer that’s genuinely designed for creators. It’s fast, precise, and packed with features that actually make a difference in day-to-day use. Whether you’re printing functional parts, artistic models, or batch jobs, it delivers consistent results without the usual resin printer headaches. For me, it’s not just a solid machine—it’s a well-rounded tool that fits right into a serious maker’s workflow.

Pros

- Fully assembled and easy to set up

- Rotatable touchscreen for flexible access

- Smart resin feed with auto-level and heating

- Z-axis linear rails for stable, precise prints

- 16K screen delivers ultra-sharp detail

- Clean, enclosed design with air filtration

- Reliable performance across all test prints

- User-friendly slicer with tailored profiles

- Quiet operation and generous build volume

Cons

- Limited to Uniformation’s resin bottle format for auto-feed

- Touchscreen rotation is manual, not motorized

- No onboard slicing or preview—requires external slicer

- Resin heating takes time to reach optimal temperature

- Air filter is effective but not replaceable by a standard part