With new technologies emerging on the market, manufacturers start looking for ways on how to optimize their costs and efforts to achieve the best quality and maximum result. Right now, there are 2 major players in the CNC and 3D Printing market that both use computer control technologies. Since 3D printing is considered to be a newer technology that opened a new chapter in building prototypes offering more flexibility, CNC is not going away any time soon because the equipment is constantly modernized and automated to reduce human involvement. Before making the final decision, let’s dive deeper into both of these technologies to see their pros and cons.

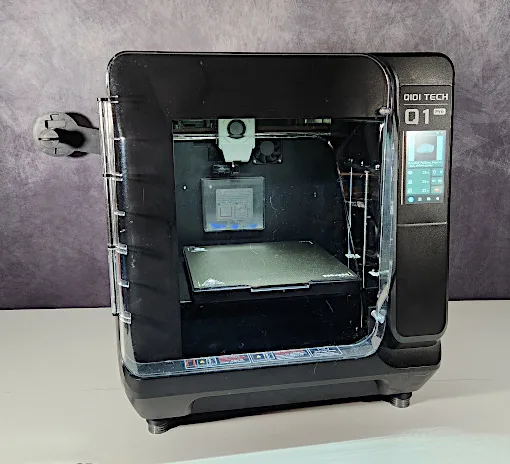

СNC Manufacturing Overview

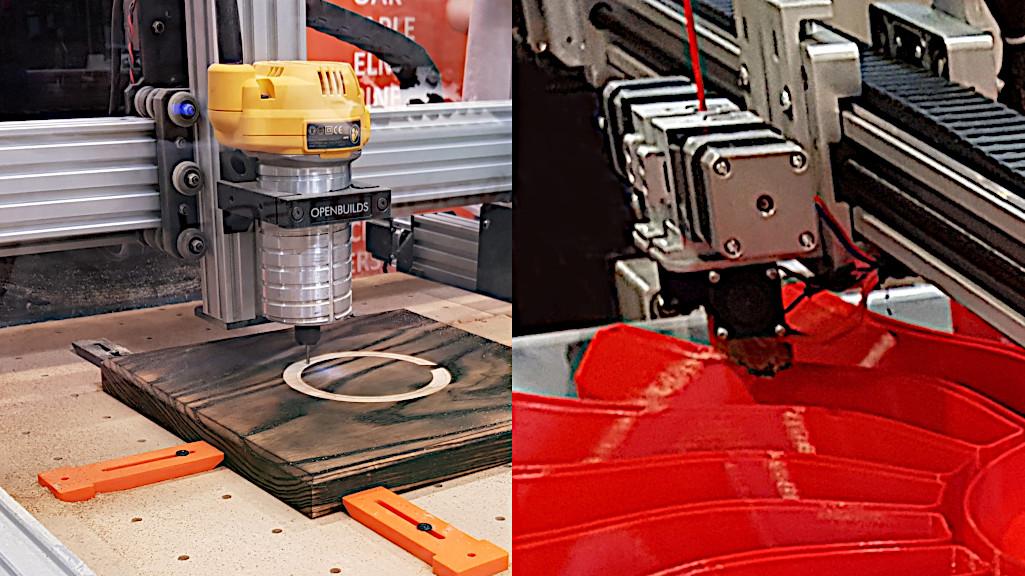

CNC (Computer Numerical Control) is a subtractive form of manufacturing that uses instructions from a computer-aided manufacturing or design program to build a product. The work starts with a larger block of material that is later subtracted to receive the necessary form of an object that is being produced. So far, this technology is dominating the market as it offers high precision of manufactured items, sustains materials with high melting temperature, and is suitable for complex processes like milling, or lathing.

(Image: 3DWithUs)

CNC Pros:

– Reliability tested by time. Entering the market in the middle of the 20th century, CNC remains the most popular technology known for its reliability, as the machines can work 24/7 and need to take a break only during maintenance.

– It’s cost-friendly for mass production. If you deal with large production volumes, the cost of manufacturing is reducing through reusing the operation setup and molding. Also, the assembly lines are much faster than the 3D printing process. Since the CNC technology is widely used on the market, you can find a used machine dealer to buy second-hand machinery at even more attractive pricing.

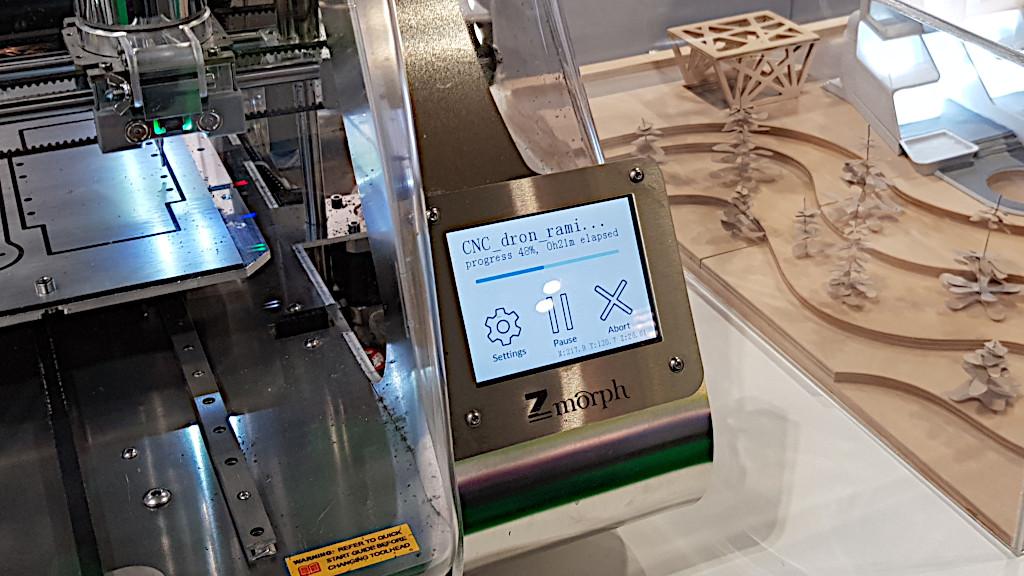

(Image: 3DWithUs)

– Tight tolerance. CNC is considered to be the best option when you need to achieve high dimensional accuracy compared to 3D printing due to the established precision control. Also, since 3D printing is dealing with the melting process through the production process, it’s harder to achieve the necessary tolerance and bears the risks of warpage defects.

CNC Cons:

– Special training and skills are required to use CNC. Despite the fact that the technologies evolved, and nowadays less human effort is required to operate machines, and the process simplified compared to the early years of CNC existence, the operator’s control over the choice of cutting path and tools is still high compared to 3D technology use.

– More waste. CNC is a subtractive technology, where the block of material undergoes processing through cutting down unnecessary parts to create the final shape. It causes a lot of waste making this process less environmentally friendly than additive manufacturing.

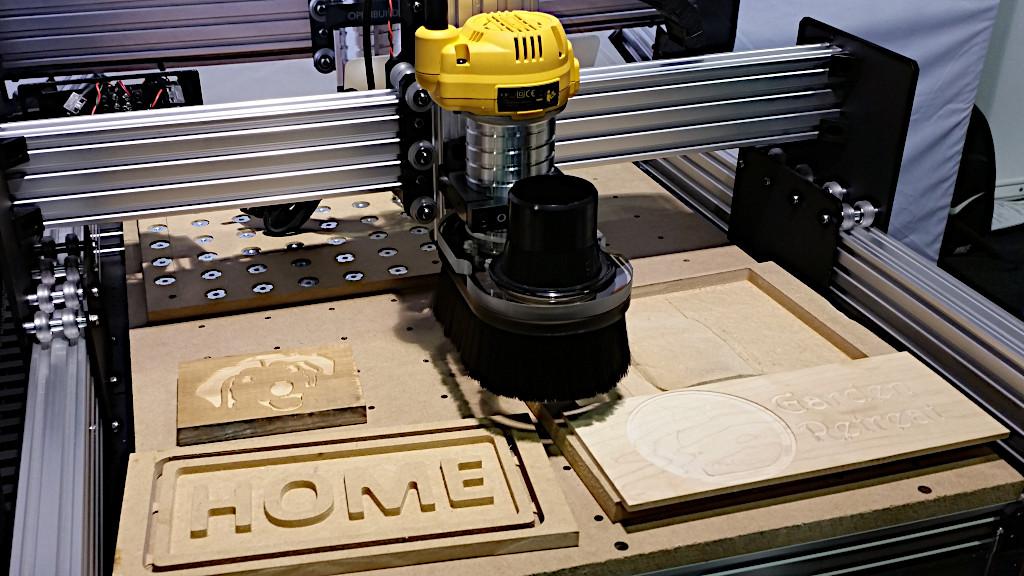

(Image: 3DWithUs)

Here is an example of a CNC Machining service provider.

3D Printing Overview

3D printing is a form of additive manufacturing that allows building separate objects or their parts creating the structure layer by layer with the help of. It revolutionized the technology world by making it possible to achieve the most accurate level of detailisation than ever before. Apart from machinery, 3D printing is widely used in almost all industries including Medicine, aerospace, jewelry, and space industries.

Read More & Compare

Read more about desktop 3D printer builds and processes. Type, volume, FDM or Resin, all to consider. Or jump to the latest 3D printer reviews.

For a comparison with other FDM 3D printers please refer to the

detailed budget FDM 3D printers guide.

For a comparison with other resin 3D printers in the same price range, please refer to the

detailed resin 3D printers guide.

Pros of 3D Printing:

– Simpler in operation. Unlike CNC that requires additional supervision, once the 3D file is prepared and minor settings like part orientation are tweaked, it can be left unattended. That leads us to the next benefit.

– Lower pricing per item than CNC. Since 3D Printing is set up as an integral process of manufacturing, the time and energy used for different stages of CNC machining is not required. Also, the labor costs are reduced as one person can take care of several 3D printing machines at a time.

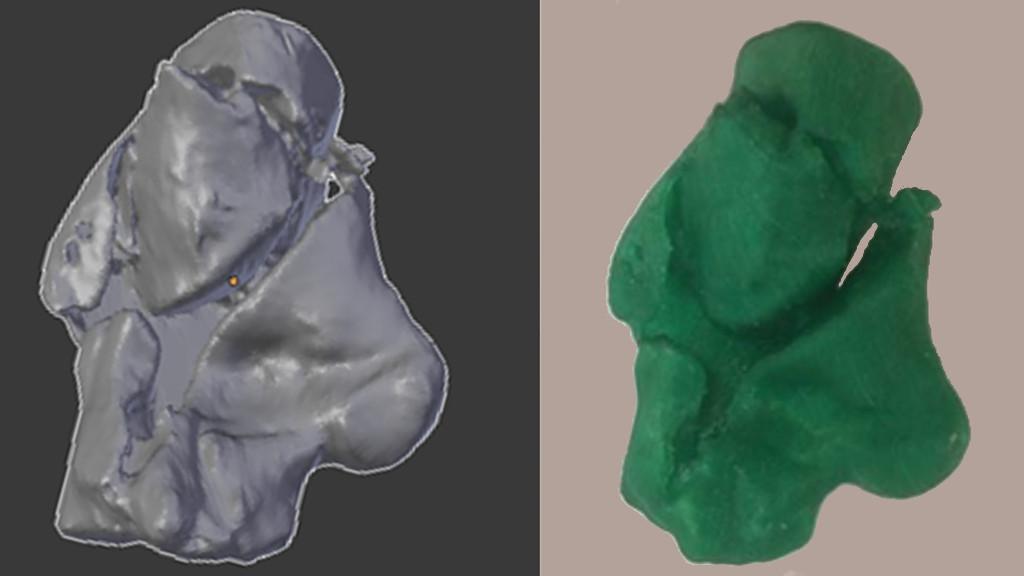

(Image: Mackay Hospital)

– Less waste. As an additive manufacturing technology where only the amount of material required to produce an object is used, there is almost no waste when using 3D printing. That’s why it’s often considered to be more environmentally friendly.

– High accuracy. 3D printing is known for replicating geometrically complex objects. Traditional CNC subtractive methods sometimes cannot offer this feature, as certain parts cannot be removed from the mold, or impossible for the machine to perform when it comes to small elements. It’s another benefit of using additive technology to be able to follow the slightest curves and achieving high detailing accuracy.

Cons of 3D Printing:

– It’s considered to be material bounded. While it’s possible to use 3D printing both with polymers and metals, due to the lower temperature it can sustain, it’s not possible to use the technology for superalloys, thermoplastic rubbers, or other materials that cannot be temperature controlled.

– Construction reliability. In 3D Printing the part construction is performed in layers that stick to one another. It may lead a part to break under the high pressure. It’s especially valid in fused deposition modeling.

– Post-processing effort. Despite the fact that 3D production is faster than CNC machining, the post-processing stage may take more time and effort starting from assembling the parts, rinsing, washing, and gluing to air dry or heating. In most cases, it also requires some cleanup and surface finish to prepare the produced items for the next stages. This also may bring some slowdown to delivering the end products.

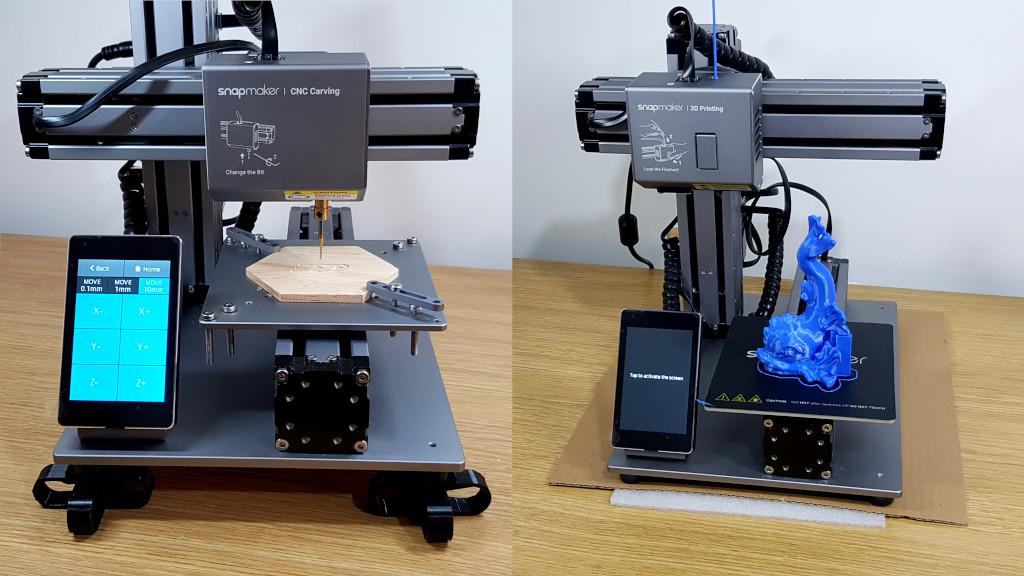

(Image: 3DWithUs)

- Read more: Injection Molding vs. CNC Machining – What’s Best for You?

- Read more: Can 3D Printing Replace Injection Molding?

Wrap-Up

Both technologies CNC manufacturing and 3D printing have their pros and cons, so there’s no unanimous winner here. Moreover, sometimes, the specifics of the manufacturing may define the technology (i.e. producing small parts with high geometrical complexity calls for using 3D printing technology). In order to make the final decision, it’s worth weighing in all the factors including the materials that will be in use, budget allocation, environmental impact, and overall production volumes.

(Image: 3DWithUs)

While these technologies are different, it’s possible to use the combined machinery method using 3D and CNC together to maximize output efforts.