Recently, well-known companies in 3D printing, Snapmaker and Polymaker, launched the collaborative product SnapDryer. It is a notable event, as the Snapmaker maker community was not only seeking a solution but also creating their own DIY variations. In this article, we will test and feature the SnapDryer, SnapDryer Box, and other filament management solutions, including DIY options, available to support Snapmaker machines – big and small, with or without enclosures.

This Guide Covers

- SnapDryer Specifications

- DIY Solutions

- What to Watch

- Compare to Other Filament Dryers

- Conclusion and Pros & Cons

Price: $55.99-79.99

Product affiliate links: 3DWithUs is supported by its audience. Purchases via some links may earn us a small commission at no extra cost to you. This helps us to continue bringing you high-quality content. Our guides and reviews remain unbiased and independent.

SnapDryer and SnapDryer Box

Official Website

PolyDryer and PolyDry Box

Amazon

SnapDryer Specifications

Modular design

Compatible with 1kg spools

Supported materials: PLA/PVB/PETG/ABS/ASA/TPU/PA/PC/PVA and other

Dimension: 235(L) x 120(W) x 290(H) mm

Recommended working environment: 20℃ – 35℃

SnapDryer Accessories and Setup

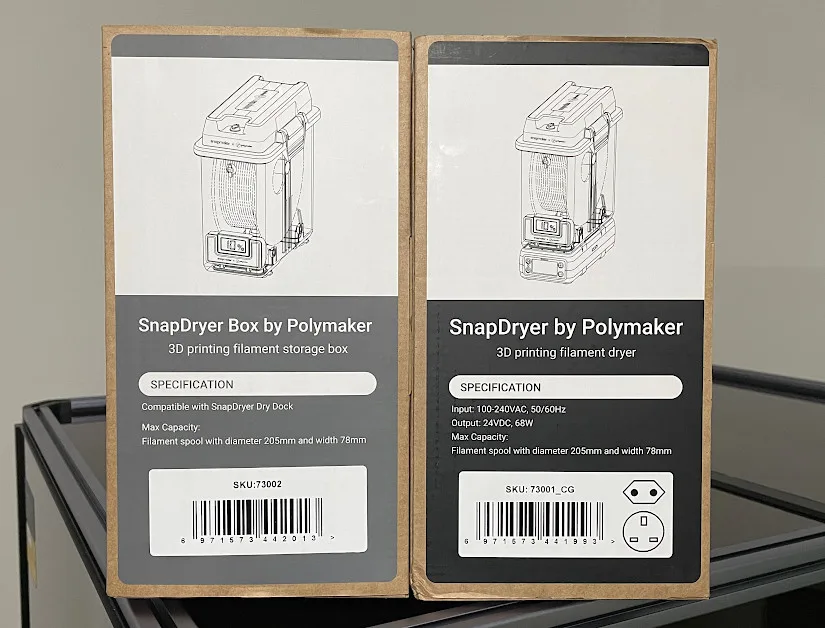

My SnapDryer and SnapDryer Box arrived in neat packaging.

©3DWithUs – and Photo: Max Funkner

– Desiccant. Adding loose desiccant was challenging – I bet I still have some beads on the floor. Holding the hygrometer box above the container proved to be a good trick for catching the escaping beads.

©3DWithUs – Photo: Max Funkner

– Spool Roller. Another part that proved to be important, especially when using long PTFE tubes, is a spool roller. Please read more in the ‘What to Watch’ section.

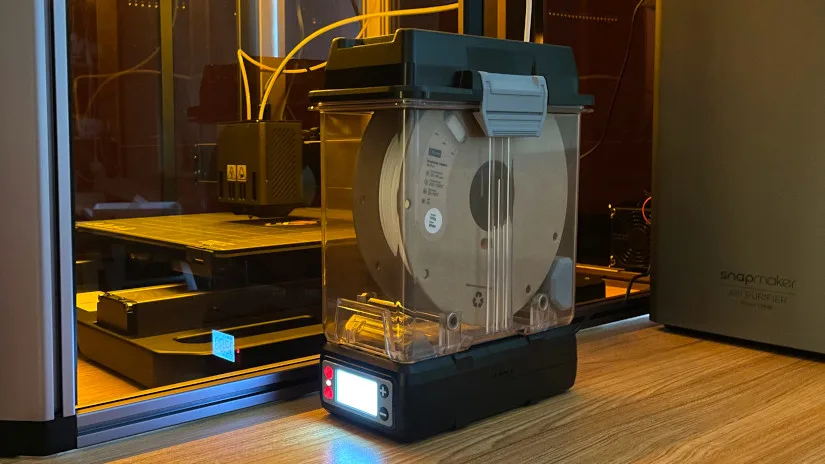

– Dry Dock and Two Containers. Only after using the system did I finally understand its full potential. The heater block can be swapped with ease without opening the box. I can easily foresee people purchasing not just a few, but a dozen containers in the future to keep their filament meticulously organized.

Both boxes fit perfectly on my existing filament rack

©3DWithUs – Photo: Max Funkner

– Snapmaker Wiki. The Snapmaker Wiki (wiki.snapmaker.com) has proven to be helpful in my experience. The SnapDryer first-time use instructions are very clear, and the resources provided are useful when needed.

SnapDryer vs PolyDryer

On 3DWithUs, Andrew Sink previously wrote a detailed review of the Polymaker PolyDryer. In addition to an unboxing, he conducted before-and-after testing by 3D printing a Benchy.

©3DWithUs – and Photo: Andrew Sink

The SnapDryer and PolyDryer, both manufactured by Polymaker, are identical in functionality. However, the SnapDryer includes additional accessories designed specifically to fit Snapmaker machines that operate with enclosures. Below are the official notes highlighting the differences between these two products.

1. SnapDryer is a collaborative brand product with Polymaker & FabNotion, specifically optimized for compatibility with Snapmaker Printers.

2. SnapDryer features detailed improvements such as the addition of a Filament Tube, Filament Entry Cover, Filament Tube Connector, Round Clamp, and Tape Measure. These improvements make it easy and hassle-free for users to adapt to Snapmaker machines.

3. After-sales service is fully handled by Snapmaker, ensuring that users can rely on the product with confidence.

Modifications for SnapDryer

The Printables PolyDryer Mods page features a growing collection of printable modifications, many of which can also be useful for Snapmaker machine owners. One example is the ‘Double Barrel Mod‘ by Printables user 3DPrintSOS, which allows users to attach two boxes to the dryer simultaneously.

Photo: 3DPrintSOS – Printables

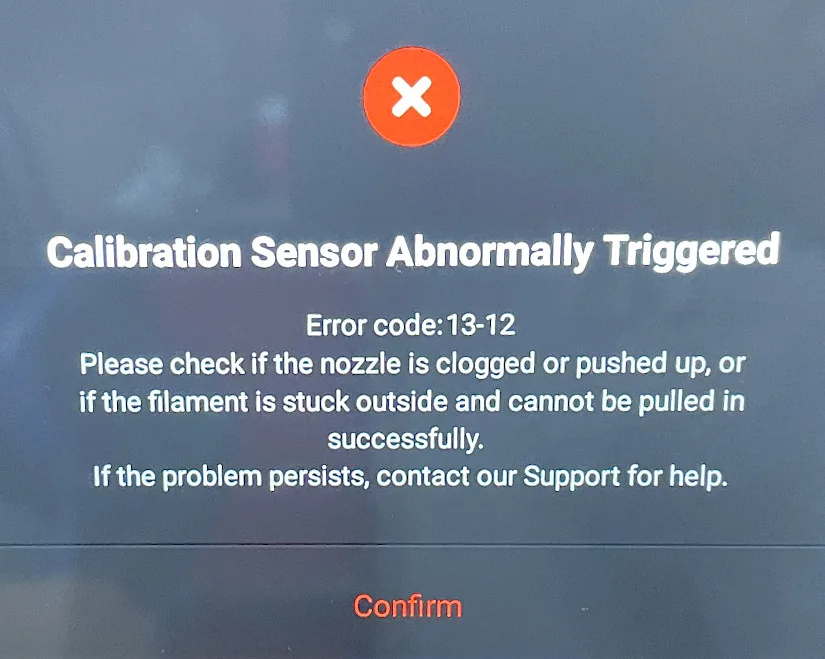

Caution: Considering the large enclosures and lengthy PTFE tubes, extra precautions must be taken to avoid triggering “Error Code 13-12” by ensuring there is no excessive filament feeding resistance.

I could not resist printing Double Barrel Mode in beige PETG. I will write more about print settings in a Snapmaker Artisan review article soon. The video above is a quick teaser of SnapDryer on YouTube.

DIY: Multi-Spool Holder for Snapmaker Enclosure

Another spool holder system that caught my attention was created by OlsenProductions on Etsy. While an open spool holder won’t protect the filament from humidity, enclosing it in an airtight container can solve that issue.

Photo: OlsenProductions – Etsy

Photo: Snapmaker

Creating DIY filament storage boxes using IKEA or other types of containers is not a new concept. However, securely assembling something both functional and practical on top of the Snapmaker enclosure is a long-term solution worth considering.

Filament Drying Solutions – What to Watch?

This serves as a reminder not only for SnapDryer users but for anyone planning to install filament drying solutions for their Snapmaker machines.

Calibration Sensor Abnormally Triggered – Error code 13-12

The large enclosures demand lengthy PTFE tubes, so extra precautions must be taken to avoid triggering “Error Code 13-12” by ensuring there is no excessive filament feeding resistance.

– No Brittle Filament. Since some tension is unavoidable, it is recommended to use only high-quality filament and avoid exotic brittle filaments. In other words, if the filament snaps easily when bent, it’s best to avoid using it.

Other Filament Dryers

On 3DWithUs, we have a detailed filament dryer comparison guide where products from brands such as EIBOS, Creality, Eryone, Sovol, and others are listed for price and feature comparisons.

Other filament dryers like the EIBOS Polyphemus or the FIXDRY are designed to process two spools of filament simultaneously, but do not have the same easy-to-use integrated storage solution offered by the SnapDryer Box.

©3DWithUs – Photo: Max Funkner

In my FilaDryer S4 review, I tested various setups with different printers and positions. However, the PTFE tubes provided with the S4 are quite short. For reference, here’s an example of the FilaDryer S4 setup on the Snapmaker Artisan. I like this setup and would love to have custom brackets to hold the S4 on top of the Artisan enclosure.

Conclusion and Pros & Cons

The SnapDryer and SnapDryer Box system has proven to be an excellent solution for drying and storing filament for Snapmaker 3D printers. It has been a significant time-saver for me while operating my dual-extruder Snapmaker Artisan. Previously, I had to store filament in plastic bags overnight to protect it from humidity, only to reload it again in the morning. Not anymore!

When listing the pros and cons of the SnapDryer, I agree with Andrew Sink’s assessment but would add that the use of long PTFE tubes may introduce extra tension and potentially trigger ‘error code 13-12’ on Snapmaker machines.

PROS:

– Fast and consistent drying

– Inexpensive PolyDryer Box add-ons

– Modular design

CONS:

– Can only dry one spool at a time

– May trigger error code 13-12 on Snapmaker machines

We will add more filament drying and storage solutions that could serve Snapmaker machines.

SnapDryer and SnapDryer Box

Official Website

This might be the best Snapmaker U1 + Snapdryer (Polydryer) mod: https://www.etsy.com/ca/listing/4435654759/multi-spool-modular-drybox-for-3d