Filament dryers play a crucial role in maintaining print quality, especially when working with hygroscopic materials like PLA and Nylon. SUNLU, a well-established name in the 3D printing industry, has expanded its lineup with the FilaDryer SP2. It’s an airtight, modular system designed to store and dry filament more efficiently, capable of accommodating two 1kg spools, or one 2kg or 3kg spool. In this article, we take a closer look at the SP2’s features, performance, and how it fits into modern filament management workflows. As usual, we’ll wrap up with final thoughts and a list of pros and cons.

Table of Contents

- Specifications

- Features and Design

- Testing and Setups

- Compare to Other Filament Dryers

- Conclusion and Pros & Cons

Pricing:

$89,99 for one set (base + 1 Box) for the first 100 sets, then $99,99

$69.99 for a box set (1box + 2 Spools of PLA + 2.0) then $74,99

Product affiliate links: 3DWithUs is supported by its audience. Purchases via some links may earn us a small commission at no extra cost to you. This helps us to continue bringing you high-quality content. The product featured was provided in exchange for an honest review. Our guides and reviews remain unbiased and independent.

Compare the Prices & Bundles:

Official Store

SUNLU FilaDryer SP2 Specifications:

Dimensions: 278 × 208 × 396mm (L×W×H)

Spool Compatability: 2×1kg, 1×2kg, 1×3kg

Filament Compatibility: Ø1.75mm / Ø2.85mm

Net Weight: 3.6 kg

Operating Environment: 10°C–35°C, RH ≤95%

Drying Temperature Range: 35°C–70°C

Humidity Display Range: 10%–90%

Max Power: 250W

What’s in the Box

Base + 1 Box Package Includes:

Drying Chamber, Heating Base, Hygrometer, Desiccant, Desiccant Box, Power Cable, Spool Roller, Air Lock x2, PTFE Tube (8cm ×2, 1m ×2), User Manual.

Here is the Base + 1 Box and 1 Box + 2 Spools Package:

©3DWithUs – Photo: Max Funkner

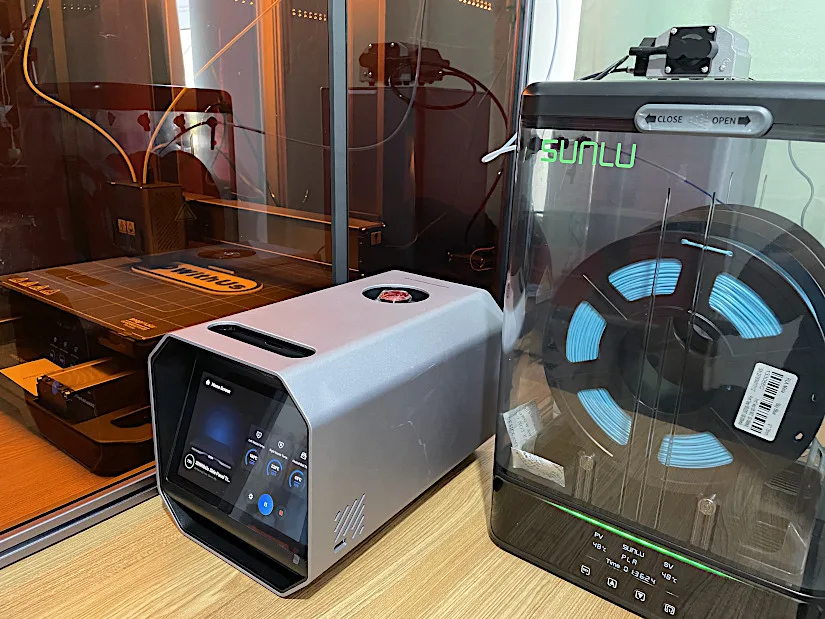

My FilaDryer SP2 arrived in a package including one Base, 2× Boxes, and 2× Spools (approximate value: $173). The two filament spools were securely packed in the second box. I’m not sure if this bundle will be available later, but it makes sense and is cost-effective in terms of transportation.

Features & Design

SP2 stands for Smart Printing, 2 for modular design.

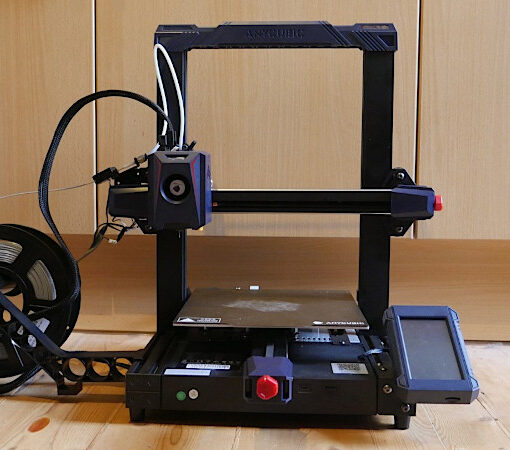

SUNLU has followed the trend by releasing their own modular filament dryer. This system not only dries the filament but also serves as effective storage and can be convenient for transportation. I’m not sure if it was intentional, but the ability to stack the boxes on top of each other is also space-saving.

– Airtight. Compared to SUNLU’s other filament dryers, the S2 and FilaDryer S4, the SP2 stands out for being airtight. The top lid closes very securely, and the bottom plugs are lined with rubber around the perimeter to ensure a tight seal.

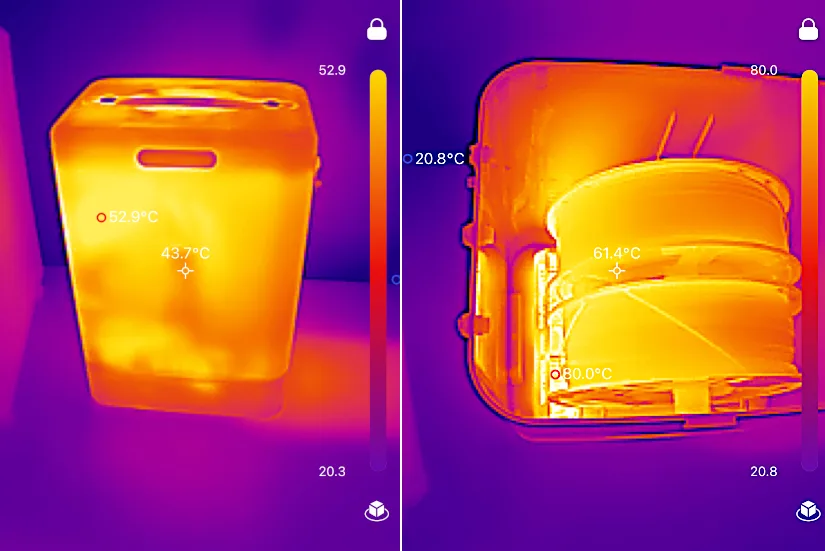

– Temperature. As promised, it maintains 70°C at the maximum setting. As shown on my infrared camera, the heating element itself reaches around 80°C, while the spools heat up to approximately 70°C. This temperature is sufficient for drying popular materials like PLA and is suitable for storing engineering-grade filaments such as PA (Nylon) and CF (Carbon Fiber blends). For drying and even annealing engineering-grade materials, the FilaDryer E2 is more appropriate, as it can reach temperatures up to 110°C.

©3DWithUs – Photo: Max Funkner

A TopDon thermal camera offers a visual view of the overall heat distribution. You can see the thermal camera view in our short YouTube video.

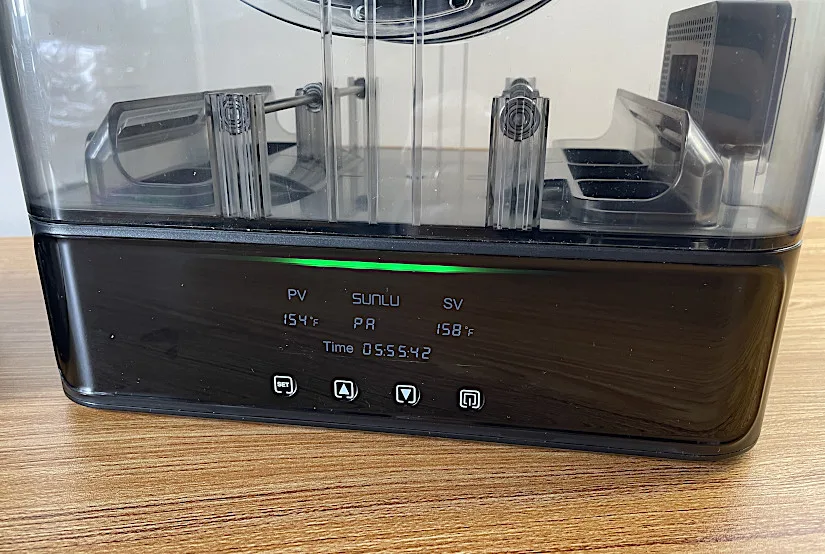

– Touch Screen. The detailed touchscreen allows you to select preset programs for common filaments like PLA, ABS, PETG, and more, with the option to adjust settings as needed. The green LED light strip can also be customized for added visual appeal. It looks spectacular in a dark room.

Testing and Setups

To learn why filament should be dry, how filament dryers help, and to read more about hygroscopicity, check out our detailed guide.

– Teflon Tubes. As the instructions suggest, PTFE tubes should be installed, especially when there’s a sharp curve in the filament path. I used the FilaDryer SP2 while printing DeathRacer side panels on the Snapmaker Artisan, using extra-long PTFE tubes (not the ones included). These tubes were 110 cm in length. The included PTFE tubes are one meter.

©3DWithUs – Photo: Max Funkner

This setup worked very well. Humidity remained at 20% even after a few days, when I printed the second side panel. I didn’t need to dismantle the heating base and assemble the bottom plug panels for that lengthy pause. Despite the dryer being positioned some distance away from the printer, there was no noticeable resistance that interfered with printing.

Here’s an example of the SUNLU FilaDryer SP2 feeding filament to the Creality K1 without a PTFE tube. It worked well with PLA, even with a slight curve in the filament path.

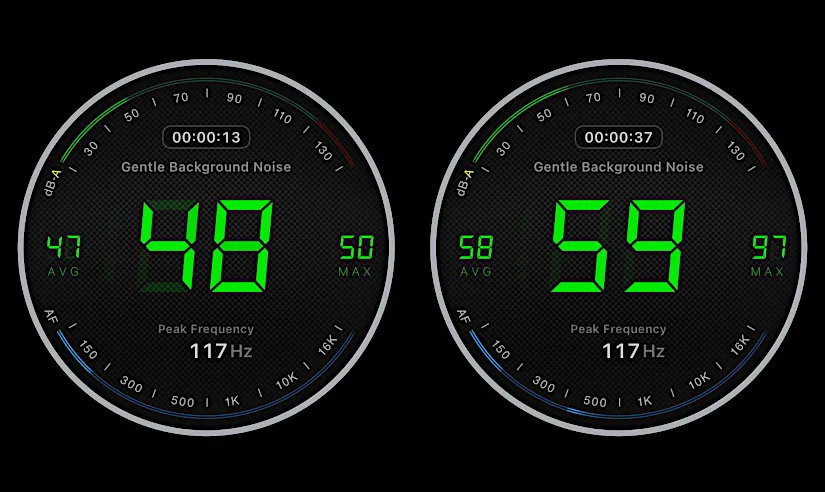

– Noise. Here are the decibel meter readings with the lid on and off. Devices like this naturally produce some noise during operation. In comparison to the FilaDryer S4, which measured 59 dB (lid on) and 73 dB (lid off), the SP2 is noticeably quieter, thanks to its airtight design.

– Open/Closed Plugs. Just a quick reminder: when the heating base is ON, it’s important to keep the side filament plugs open to allow warm, humid air to escape. Once drying is complete, close the plugs for storage. This method makes it easy to reach and maintain a humidity level of 15–20%.

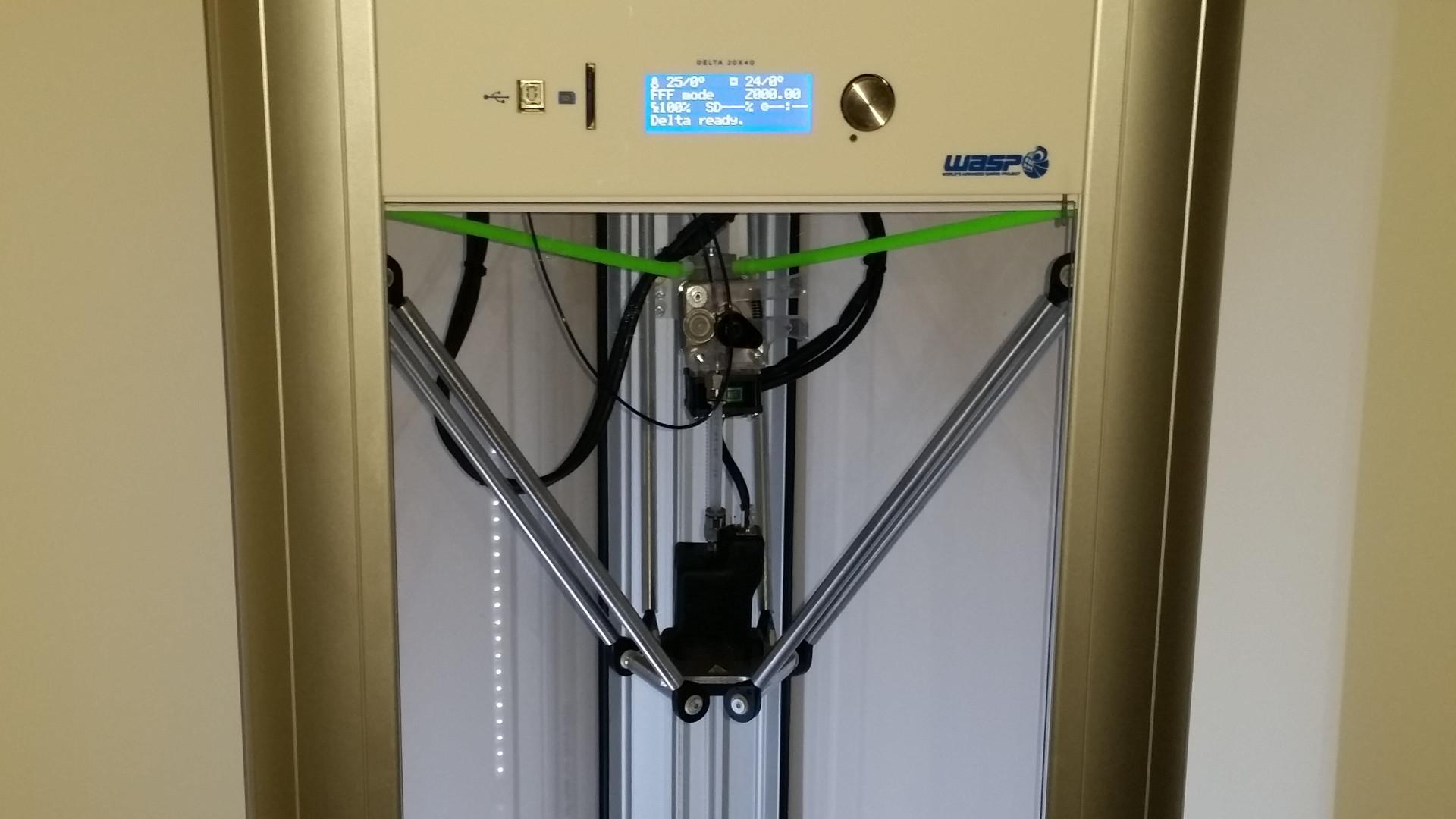

Other Filament Dryers

On 3DWithUs, we have a detailed filament dryer comparison guide where products from brands such as EIBOS, Creality, Polymaker, Sovol, and others are listed for price and feature comparisons.

Other filament dryers, such as the EIBOS Polyphemus, are also designed to hold two spools or a single 3KG filament spool. PolyMaker’s PolyDryers also offer an integrated storage solution with their PolyDryer Box. In comparison, the SUNLU FilaDryer SP2 offer airtight modular storage solution for different spool sizes.

In comparison with other SUNLU FilaDryers, S2, S4, and E2. While the S2, S,4 and now SP2 are suitable for consumer-grade filaments, the E2 is designed for engineering-grade filaments and includes an additional annealing function.

©3DWithUs – Photo: Max Funkner

Have questions? Feel free to ask in the comment section below.

For a wider discussion or to share your own SUNLU SP2 experience, join us in the forum:

Conclusion and Pros and Cons

Compare the Prices & Bundles:

Official Store

SUNLU FilaDryer SP2 Review

Review Summary

Well-known 3D printing filament manufacturer SUNLU has been offering filament maintenance solutions for years. It’s no surprise they continue to upgrade their systems, as their R&D team explores better ways to preserve filament quality—even after the packaging has been opened.

The FilaDryer SP2 is SUNLU’s answer to a modular, airtight storage and drying solution.

I’ve used the device extensively and have been pleased with its performance. The storage boxes are relatively large – designed to accommodate spools up to 3 kg, as well as standard 1 kg spools. Any remaining space can be effectively used for extra desiccant bags to enhance drying and humidity control.

Pros

• Modular

• Airtight

• Touchscreen Interface

• Handle for Easy Transportation

Cons

• Relatively large volume and footprint