On this website, we have already featured wood composite filament in a few guides. To test Timberfill by Fillamentum, was something special though, as four colors are gorgeous. It became even more exciting when Fillamentum announced that four more shades were added to their Timberfill collection. In this article, we will test the filament with both 0.4mm and 0.6mm nozzles, print a few interesting models and share some valuable tips & tricks.

This Guide Covers

- Filament Specifications

- About Fillamentum and Their Timberfill Range

- Packaging and Unboxing

- Test Printing with 0.4mm Nozzle – Tips & Tricks

- 3D Printer of Choice and Other Devices

- Scanned Tree Trunk Project

- Test Printing with 0.6mm Nozzle – Tips & Tricks

- Stringing – Tips & Tricks

- Conclusion and Links

Fillamentum Timberfill Specifications

Wood element: Spruce

Recommended printing temperature: 165 – 185°C

Recommended bed temperature: 40-55°C

Recommended speed: higher than usual

Recommended nozzle size: 0.5mm for 1.75mm and 0.6-0.8mm for 2.85mm filaments

Weight on the spool: 750g (980g total)

Shades: eight (Cinnamon, Champagne, Light Wood, Rosewood, Southern Pine, Charcoal, Terracotta, Redheart)

Price: €35-44

Official Website

-20% Discount Code: 3DWithUs20

About Fillamentum and Their Timberfill Range

Fillamentum is an award-winning filament manufacturer from the Czech Republic. Their filaments are shipped to more than 62 countries, they are active on social media and we can see them attending major industry tradeshows.

A few years ago, they launched a trademarked Timberfill® range of filaments that strongly resemble real wood as well as having wood characteristics. Models, when printed in Timberfill, temporarily smell and feel like objects carved from wood. Also, objects can be sanded and treated. Such material is also biodegradable by industrial composting. Initially, there were only four colors: Cinnamon, Champagne, Light Wood, and Rosewood. In 2022, four more colors Southern Pine, Charcoal, Terracotta, and Redheart were added to the collection.

Image: Fillamentum

Packaging and Unboxing

I received four spools in a well-packaged box. For me, unboxing 3D printing goods is similar to receiving a Christmas present for a kid.

©3DWithUs – Photo: Max Funkner

Regarding the resealable foil bags. In two of them, the vacuum was preserved, and in two of them wasn’t. There were no quality issues connected to the moisture. Desiccant dehumidifiers were present in all bags. I get the idea of such resealable bags and I tried to use them in the past, but I found them to be less comfortable than inexpensive zip-up freezer bags from supermarkets.

©3DWithUs – Photo: Max Funkner

Stickers. And I got more stickers for my ever-expanding collection. I remember I got some Fillametum stickers from the tradeshows, but these were new and fun. Sticker messages read the following: Extruding the Future; Life is too short for bad filament; One filament rule them all; I want it, I need it, I print it.

Test Printing with 0.4mm Nozzle – Tips & Tricks

The recommended nozzle size is 0.5. However, as most consumer and budget 3D printers are equipped with 0.4 nozzles, I will show you a few tricks on how to minimize the risk of nozzle-blocking.

©3DWithUs – Photo: Max Funkner

The featured model is Slightly Overengineered Olpe Vase by Nat A Cyborg.

– Vase Mode. As there are no retractions when printing such models in a vase mode, and the filament flow is continuous, there is no time for the wood particles to be burnt and block the nozzle. Models that are designed for a vase mode 3D printing are the safest for wood filament. But even with such type of design, I would recommend to regularly do the following trick.

– Clean the Nozzle. In between the prints, I recommend cleaning the nozzle by running through a trusted PLA. Load/Unload the filament. I have to admit that the direct drive extruder systems are better for such a task. It takes less time, compared to Bowden systems, to repeat this procedure until the nozzle is clean.

– Temperature and Speed. A very high temperature is an enemy to wood particles, as they get burnt easily. Therefore, we can see that the manufacturer recommends as low as 165 – 185°C printing temperature. And the increased speed is also recommended to keep the wood particles passing through the nozzle as quickly as possible.

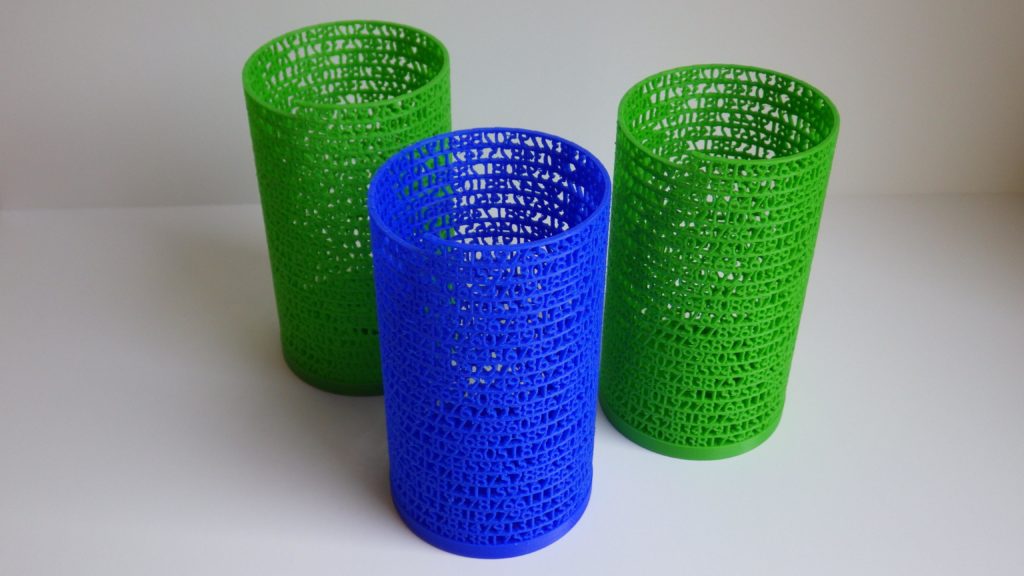

©3DWithUs – Photo: Max Funkner

I would say that this filament is very sensitive to temperature. The first Slightly Overengineered vase, which I printed at 200°C, produced cobweb-like strings. The Cinnamon Timberfill print on the right in the image above. The rest were printed at 180°C without any issues.

After trying a few prints, I would recommend printing with the 0.4 nozzle only objects in a vase mode or small prints with minimal retraction.

In the past, we published a few guides about wood filament and can say that this is a tricky material to deal with. But the results are highly rewarding and come out looking like carved from wood. And if you are ready to try a bigger size nozzle, wood filament is the best thing to play with. Bigger and more-pronounced layers work as an added bonus and, in many cases, remind us of tree rings.

3D Printer of Choice and Other Devices

I intentionally timed the Fillamentum Timberfill review together with Elegoo Neptune 3 Plus review because the 0.6mm nozzle suits well Plus sized volume machines for quick large-scale prints. Of course, it should work even on budget 3D printers that can accommodate a wider-size nozzle. I feel that a direct drive extrusion system is better suitable for such filament. The filament is brittle, even in its prime state, and can get easily snapped if there is extra friction while traveling in long PTFE tubes. The following device can help to fight brittleness and to remove excessive moisture.

Filament Dryer

Fillamentum Timberfill is a brittle filament. When bended, the filament snaps easily. After absorbing moisture, it gets even worse. To make sure that the filament is in the best condition, it is important to store it with a desiccant dehumidifier. I keep it in a dryer box overnight before printing if I know a particular spool will be involved in the important, long-time printing project. Eryone Filament Dryer Box from Amazon is one of such affordable devices that can keep your filament drying at a particular temperature. In their printing guide, Fillamentum recommended keeping filament at 50°C for 2–3 hours. On my dryer device, this is the 2nd setting. Recently, we published a comparison guide featuring drying boxes.

©3DWithUs – Photo: Max Funkner

It is important to mention, that, with the filament being brittle, the objects feel very strong. As part of the ongoing Tree Trunk project, I printed a Dawn Redwood Ogre Mace in Cinnamon Timberfill. The mace feels very solid, any respectable Ogre would be proud to have it. Check the MP4.

Dawn Redwood Trunk, Precursor Vase, and Ogre Mace

If an ogre in the forest would have a mace, it would be probably made out of Dawn Redwood.

©3DWithUs – MP4: Max Funkner

Scanned Tree Trunk Project

A little bit about the Scanned Tree Trunk, Stump, and Bark Texture Project that I keep featuring. Generally, it is a collection of design and 3D print ideas of what can be made from 3D scanned trees. There are many trees that carry a piece of history, or a sentimental value, or that are rare varieties in some well-kept gardens. I have a few free and premium files to download from my collection on Cults, but on 3DWithUs, we would like to encourage people to follow this idea and, together with the 3D printing technology, to achieve original and unique results using local trees. And scanning such objects became easier than ever before, check my Polycam app review.

©3DWithUs – Photo: Max Funkner

Wood composite filaments and 0.6-0.8mm nozzles are the best picks for such a project. A wide range of colors in the Fillamentum Timberfill series added even more fun as we can play with different shades featuring various combinations.

Test Printing with a 0.6mm Nozzle – Tips & Tricks

As I mentioned before, for large-volume printers, 0.6mm nozzles are an obvious choice. Big projects’ 3D printing time, coupled with the optimized slicer software settings, can be reduced by 50% easily. The biggest issue, I would say, is that when we print big items, the filament runs out much quicker.

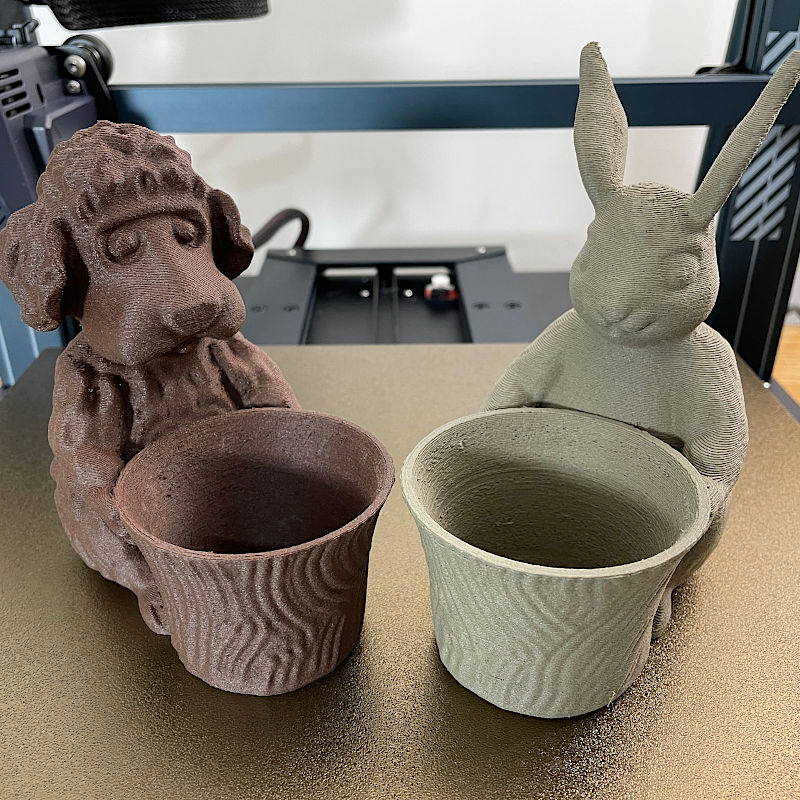

©3DWithUs – Prints & Photo: Max Funkner

Apart from Tree Trunk Project, I also printed models from my Toy Pot Planter collection. Easter Bunny and Dog The Gardener look so much better in wood material. These models feel like being carved from wood. Also, these models are good to start the gardening season with kids, and the natural feel of the wood brings us closer to nature. But as these models were designed to be printed with a 0.2mm layer height, and some adjustments should be considered when printing them with a 0.3mm layer height. If this is the case, then in order to print the underarm places without supports, the model should be scaled to at least 150%.

©3DWithUs – Prints & Photo: Max Funkner

And the last pick to test Timberfill was a Baby Fish model, inspired by the Thames River Lampposts. There was some stringing between the body and the tail but it was easily removed by a heat gun. I really liked the color spectrum on these cuties.

©3DWithUs – Photo: Max Funkner

Stringing – Use the Recommended Temperature Settings

Excessive stringing is a known issue with the wood filament and, with the right settings, strings resemble a cobweb. In the image below, I used my model Bunny Ears to test the stringing, and here is the result. Both tests were printed with the 0.6mm nozzles. One at 200°C on the left and the other at 170°C on the right.

©3DWithUs – Photo: Max Funkner

In any case, such cobweb strings are easily removed with a heat gun from Amazon. For example, the Baby Fish featured above, all had stringing between the body and the tail. A heat gun quickly removed them without leaving any marks.

Conclusion

I hope you liked my Fillamentum Timberfill review. As I still have some filament left, I will update this article in the future with the new media of printed models. If you have any good ideas of what to test print in this filament, please leave a comment below. I would be happy to review another four shades of Timberfill and hope Fillamentum will send me them to test and support my Tree Trunk project.

Image: Fillamentum

Official Website

-20% Discount Code: 3DWithUs20

Read more: Fillamentum PLA Extrafill Review

PLA Extrafill is Fillamentum’s trademark blend of PLA and owing to its name, not all is what it seems with most of their 36 colour range. PLA Crystal Clear – as its name suggests is a clear or transparent/translucent filament. Read more