In a world where innovation often leads to waste, the rise of 3D printing has brought forth a unique challenge: what to do with the surplus materials and failed prints that accumulate in its wake. Yet, within this challenge lies an opportunity – the art of upcycling. By harnessing creativity and ingenuity, we can transform 3D printing waste into something beautiful, useful, and sustainable. Welcome to the world of upcycling 3D printing waste, where discarded creations find new life and environmental consciousness meets artistic expression.

This Guide Covers

- Upcycling vs Recycling

- Leftovers After 3D Printing

- Examples

- Upcycled From Supports Jewelry Holder

- Upcycle Projects Using 3D Printer ‘Poop’

- Wipe Towers

- Shredded and Melted 3D Print Fails

- Leftover Filament Bits

- Conclusion

Upcycling vs Recycling

In the realm of 3D printing, the terms “upcycling” and “recycling” offer distinct approaches to addressing waste management and sustainability. Recycling involves breaking down materials into their raw form for reuse, often through processes like melting and reforming. While this method is valuable, it can be challenging with 3D printing due to material degradation and contamination. Upcycling, on the other hand, takes a more creative and holistic approach. It involves repurposing waste materials into new and often higher-value products without breaking them down entirely.

Leftovers After 3D Printing

Many people who use 3D printers are familiar with a common problem: leftover waste. This waste includes things like brims, supports that look like trees or pipes, ‘poop’ (plastic waste when changing filaments), and wipe towers. Sadly, most of this waste just gets thrown away. Even though companies are trying to reduce it, we still have to deal with it for now.

Upcycled from 3D Printing Waste Examples

Below, we present a collection of examples showcasing the creative possibilities of upcycling 3D printing waste created from desktop FDM or resin 3D printers. From functional organizers to artistic sculptures, these projects demonstrate how discarded materials can be transformed into new and valuable creations, inspiring sustainable innovation and environmental consciousness. Given our commitment to keeping this guide regularly updated, we invite you to share any other unique projects with us. Please leave the comments below. Your contributions are valued and appreciated!

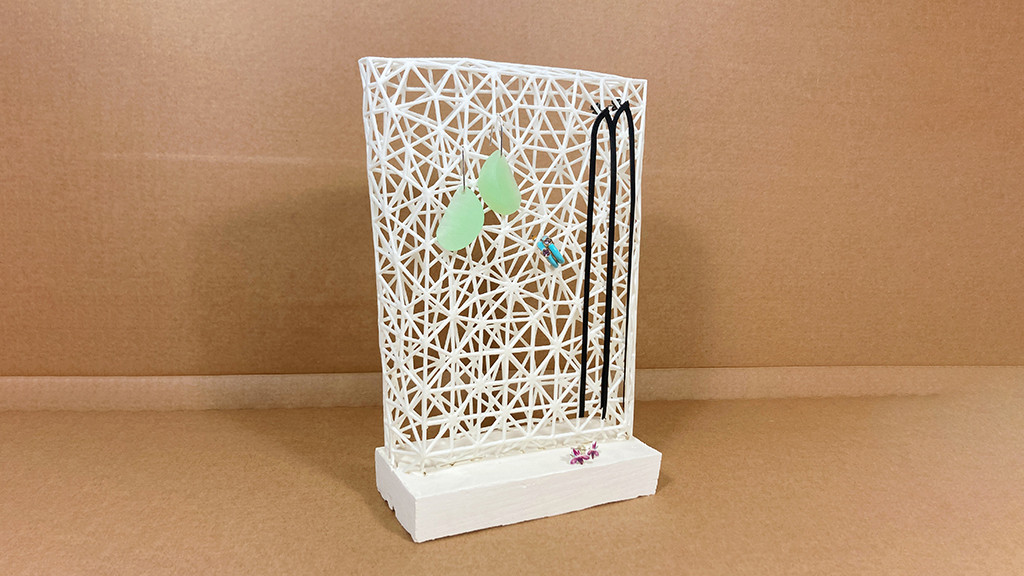

Upcycled From Supports – Jewelry Holder

The inspiration for the Upcycled From Supports Jewelry Holder struck Laila unexpectedly during a meeting at Rapidnext. Amid discussions about printing options for her latest project, she found herself presented with a pile of waste supports. Seeing their intriguing triangular structure, she immediately envisioned their potential as earring stands. With nylon in hand—flexible yet durable—she recognized the opportunity to transform this waste into something both functional and visually appealing.

Photo: Ivana Laila Drobná

To make sure the jewelry holder stayed steady, Laila came up with an idea to make the base a bit bigger than the support’s bottom. She used airdry plaster from Jovi as the material. However, it didn’t work very well as it was too clumsy and often cracked. She admits that different materials and methods may work better. Despite the challenges, Laila eventually sanded and glued the structure together, and as a result, she turned the leftover supports into a useful jewelry holder, showing how innovation and determination can turn problems into solutions. Learn more about Laila and her projects here.

Upcycle Projects Using Filament Poop

What is Filament or 3D Printer Poop?

Filament or 3D printer poop is a term used humorously in the 3D printing community to refer to the small blob or strand of excess filament that is extruded from the 3D printer’s nozzle when the filament is being changed or loaded. It often occurs as the new filament pushes out any remaining residue from the previous filament, resulting in a tiny blob. While it may seem insignificant, filament poop can affect the quality of prints if not properly cleaned.

©3DWithUs – Photo: Will Zoobkoff

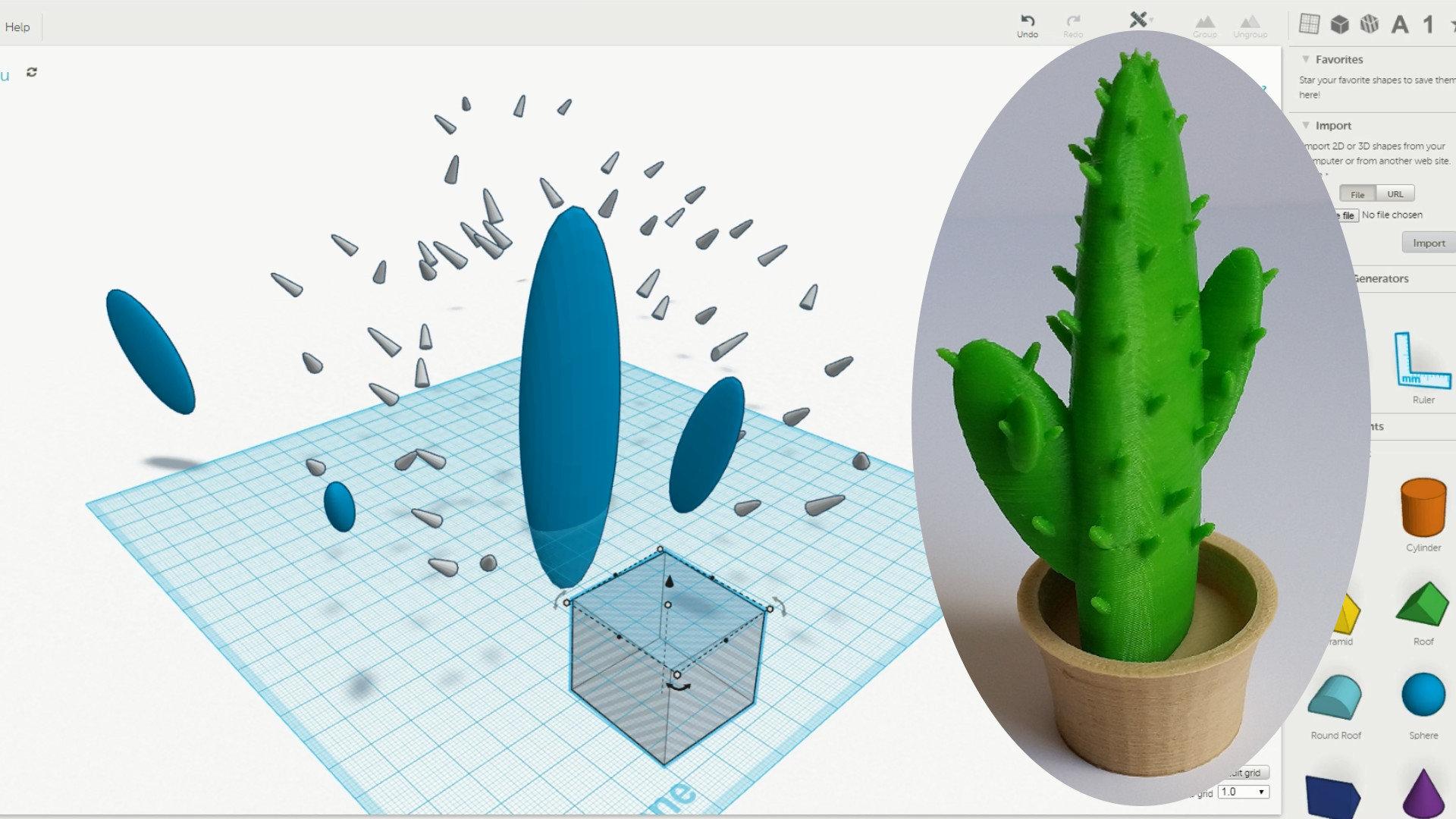

CFS (Creality Filament System) vs Snapmaker IDEX (Independent Dual Extruder)

©3DWithUs – Prints and Photo: Max Funkner

To recycle filament poops, they can be shredded and transformed into new filament using filament makers. However, makers and artists already employ this newly found raw material for their molding projects. They use such vibrant filament waste as casting material for silicone molds, injection molds or to create blocks for further CNC carving.

Image: Morgii

Some other practical and fun uses of printer poop waste:

Poop Tower Game

Drainage Media in Plant Pots

Insulation for 3D Printer Enclosure

… more to be added.

Wipe Towers

As multicolor 3D printing becomes more prevalent, it brings about a new form of plastic waste in the shape of wipe towers. These towers are created during printing when the extruder switches filament colors. Wipe towers serve the purpose of maintaining clean color transitions and stable filament flow.

Image: Prusa Research

Image: Vartifex3D

Although leading slicer software offer various optimization settings to minimize filament waste, including options for wipe objects, these objects, whether with or without post-processing, can still be repurposed for different purposes. Wipe towers can vary in shape and size, offering versatility in their potential uses.

Image: Prusa3D

Shreded and Melted 3D Print Fails

Similarly to 3D printer poop, failed prints can be sorted by color, shredded, and used as casting material for silicone molds, injection molds, or to create blocks for further CNC carving. This allows for the creation of artistically unique designs and patterns.

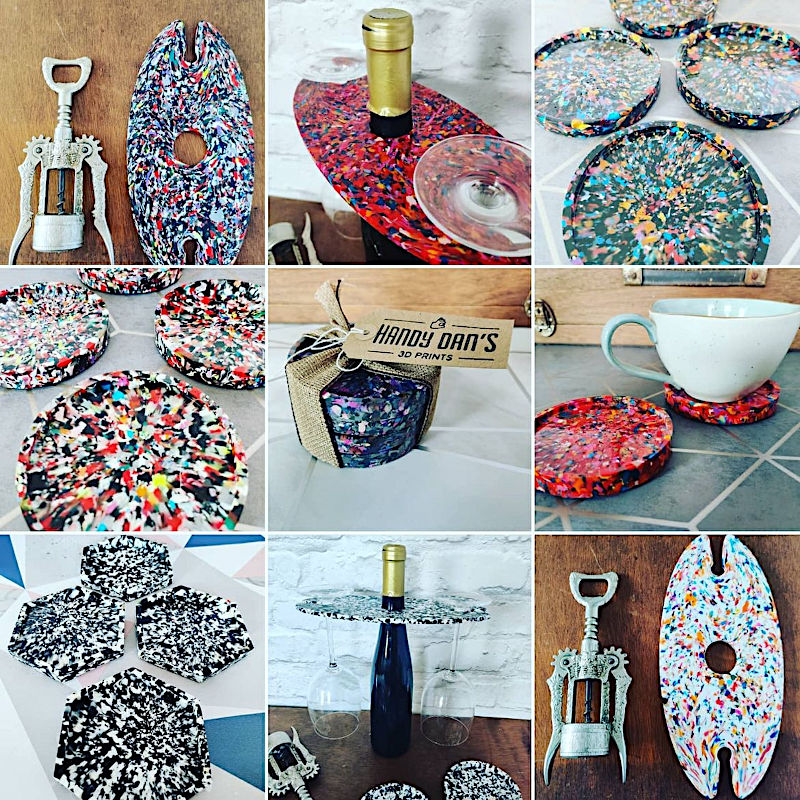

Image: Handy Dans 3D Prints

Handy Dan’s 3D Prints on Instagram showcases a remarkable collection of creations, ranging from coasters to wall-mounted clocks, all made from recycled and upcycled 3D printing waste. Moreover, they operate an Etsy shop where these unique creations are available for purchase. This serves as a successful example of recycling and upcycling within the 3D printing community.

Leftover Filament Bits

I haven’t come across an artistic example of upcycling such waste yet, but there’s certainly a case for addressing plastic waste. Leftover filament bits are often overlooked and discarded. The issue is that unused filament, especially PLA, absorbs moisture over time, making it brittle and unsuitable even for simple tasks like color changes with a pause. Fortunately, the recent introduction of filament dryers can address humidity issues, allowing leftover bits to be used for various projects. In any case, if you have such bits on hand, don’t dispose of them as waste.

Conclusion

While the 3D printing community awaits affordable solutions and practical waste management services, which are on the rise, artistic upcycling not only conveys a message but also cultivates various solutions. These range from optimizing initial 3D print jobs in slicers to reusing support structures or using shredded plastics as materials for molding projects. We hope you found our guide helpful. Committed to regularly updating it, we invite you to share any other unique upcycling projects with us. Please leave your comments below; your contributions are valued and appreciated!

Read more: Recycling in 3D Printing: Filament Spool Initiatives – Cardboard, MasterSpool, etc.

Recycling in 3D printing remains an ongoing and sensitive topic, particularly for many FDM desktop 3D printer users who grapple with plastic filament waste. Over time, they accumulate numerous failed prints, leftover material, and empty filament spools. Fortunately, several initiatives from both 3D printing material manufacturers and community members are already underway. A notable example is MasterSpool project, which encourages to create one lasting spool, the reuse of empty spools or their production in cardboard.