Nowadays devices across the vertical production line in the 3D printing industry race to keep up with innovation. We are going to look at one of the crucial aspects of the industry, and one that really drives innovation at lightspeed – the filament makers! We will see how they work, why they are needed and check the applications.

This Guide Covers

The What and How of Filament Makers

For starters, let’s get some context about filament makers. These devices create the consumable material from plastic pellets (or granules) to a spooled filament that FDM 3D printers use.

The main components of the filament maker include a hopper, extruder, cooling system, sensor, positioner, and a spool winder.

For example, 3devo’s Precision and Composer series filament makers have the following process:

1. You put your material (usually in small batches) into the hopper of the filament maker, which takes it to the extruder zone.

2. At the extruder zone, an extruder screw rotates in order to push the material out to the other end. Throughout this stage, there are a total of 4 different heating zones, each of which is controlled independently and each reaching a maximum of 450°C.

3. When your material has gone through the extruder stage, it will come out of the device as filament but it’s not yet ready. Coolers are attached at this point to solidify the filament. Since it just came out of the oven, it needs to cool down before being spooled.

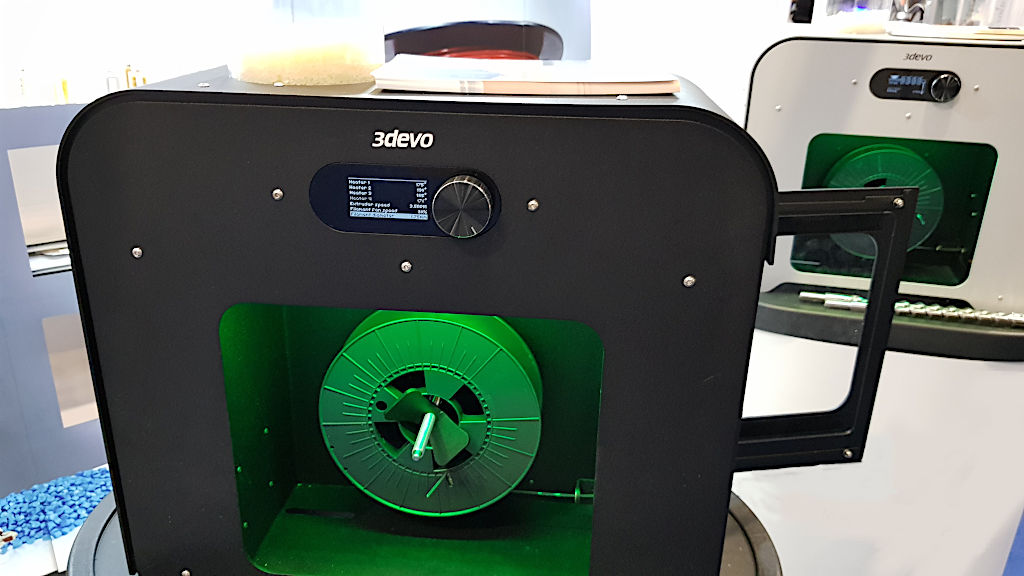

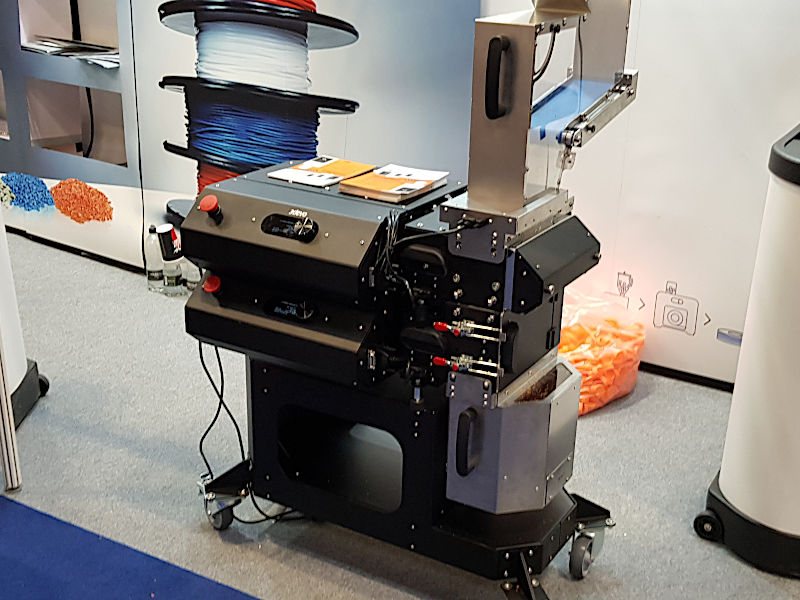

3devo Filament Maker at TCT3Sixty

MP4: Max Funkner

4. Under those coolers is a sensor that indicates the diameter of your filament. Different printers have different compatibility with filament diameters. The most common one, as you probably know, is 1.75mm or 2.85mm. The sensor has a puller system installed that regulates the diameter of the filament based on the settings you’ve set.

5. Once it’s cooled and passed through the sensor, it is time to go through the positioner. That is the part of the device that regulates the proper neat rolling of the filament onto the spool, so it is ready to use once it’s done.

6. The positioner regulates the placement of filament across the spool, and the spool winder is the place where you place your empty spool with a clutch and attach the beginning of your filament. After that, it just rolls with it.

Applications

Let’s list some of the applications where filament makers can be used.

Research & Development

When it comes to researching types of materials, the filament maker is the perfect device for that. It provides an environment for the chosen material, which you can easily control with precision in order to record and report on the processability of a wide range of materials. Scientists have capitalized on the opportunity, with many experiments resulting in the discovery of a new type of material, or the discovery of an unknown occurrence in existing materials.

This insight allows the implementation of findings into many industries across the board. Often those findings result in changes in the status quo that save resources, time, expenses, or all three, and provide more sustainability, efficiency, new solutions, and more.

Manufacturing & Production

Filament makers play the role of giving small-scale opportunities for companies to find the most appropriate materials for their purposes. Insights reveal how long it takes to extrude filament depending on the type of material, how much resources and manpower is required, and thus make an informed decision as to what type of material different companies should take to the industrial level.

This saves companies an incredible amount of time and resources and provides them with a solution that is sustainable and minimizes plastic waste (in Audi’s case, they repurposed ABS plastic, which was previously considered waste and thrown away, all thanks to filament makers). All in all, filament makers’ impact is quite significant when it comes to saving up on resources and time.

Recycling & Sustainability

What previously was considered waste, can now be repurposed into the production process due to filament makers. Not only that but depending on the type of plastic, materials can be used multiple times (some even without losing their strength and overall properties). Undoubtedly, the benefits of filament makers are a game changer, not only for the 3D printing industry but any other industry that can implement new knowledge of materials.

Image: Max Funkner

Why Are Filament Makers Important

The complexity behind the process comes from the integrated control panel. There you have all the settings you need to get your desired results. The most important ones are the temperatures of each heating zone, as well as the speed at which the filament is extruded.

The software system attached to the filament maker has the purpose of providing as in-depth an experience as possible, thus giving users the details behind the process – how the material reacts to specific conditions, and how that changes across the board of settings and types of materials.

Yes. It’s generally tough to work with a filament maker, but that is why it’s all the more worth it. Due to the detailed procedure, the applications for such a device transcend industries and go beyond. Having a way of analyzing your chosen material can greatly improve your knowledge of different materials, as well as compatibility and the potential to mix and match in order to create a new type of filament. The possibilities are endless, and we’ll go through the most important ones.

Conclusion

Taking a step back from 3D printers to look at the bigger picture undoubtedly opens up a range of possibilities to explore, both as a business and a researcher. With the deep and detailed control over the environment of the process, new seas could be explored, thus exposing the 3D printing world (and not only) to an array of unknowns that are waiting to bring innovation and breakthroughs in our lifestyles.

A filament maker doesn’t simply make filament. It lays the foundation for someone out there (maybe you) to explore the possibilities of all those unexplored materials, and be the change they want to see.

Read more: Filaments – Popular Types and Innovations

In these innovation-rich times, new interesting 3D printing filaments come out to the market on a yearly basis. If some 3D printing materials keep breaking records in specifications and properties, then others are created for those who like to play with some fun features. At times, it is hard to find your way around in the sea of different filaments.