Flexible filaments, including TPU and TPE, are not as frequently used in 3D printing as PLA or PETG. The reason may be that 3D printing using such materials requires certain skills together with the good knowledge and feel of your machine. Also, slicer settings, like in Cura or Simplify3D, have to be adjusted individually. Not all objects can be printed in flexible material. For example, designs with joint parts, that work well in PLA or ABS, may require modification to suit flexible filament. This post is updated frequently with brief reviews, pros and cons, and ideas for 3D printing.

Table of Contents

- Extrusion Type for Flexible Filament

- SainSmart TPU Filament Review

- NinjaFlex TPU Filament Review

- Filament PM TPE Filament Review

- Vase Mode 3D Printing with 0.8 mm Nozzle – Water Tightness Test

- What to 3D Print?

(Photo: 3DWithUs)

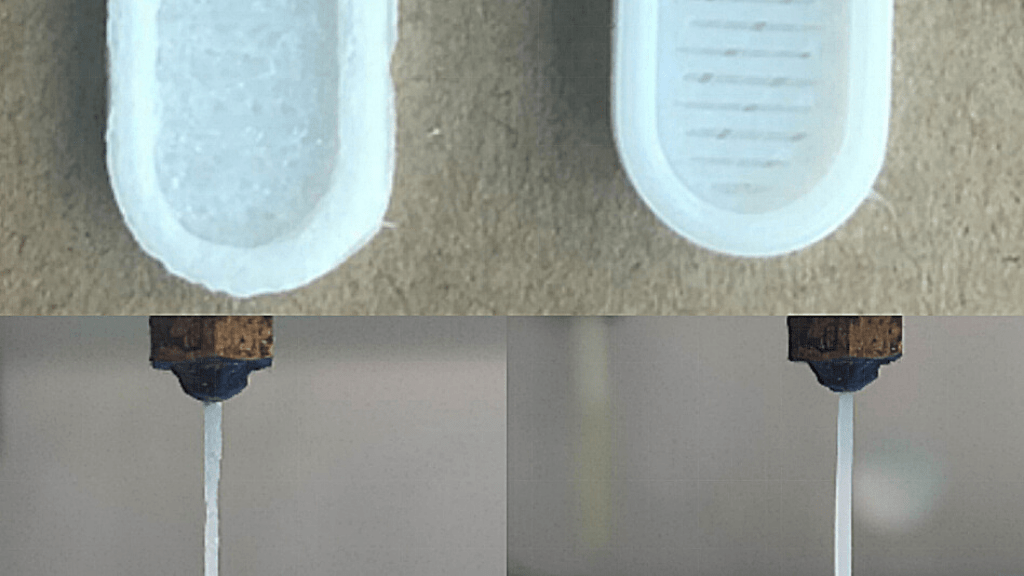

The Best Extrusion Type for Flexible Filaments – Bowden vs Direct Drive

Before getting into the filaments department, one important aspect should be considered – extrusion type. Direct drive extrusion is the best choice, no competition here, as the higher the flexible filament’s “Shore” (the extent of flexibility, softness) the harder it is for Bowden systems to achieve a successful print. We 3D printed using this type of material on both types of 3D printers: Bowden – Delta Wasp 2040 and Direct Drive Original Prusa i3 MK2.5S. For Bowden, we had to tweak the slicer settings very carefully. The worst part is that print failure may happen at the end of the print, when the soft filament jams in gears at some point. For this reason, the slicer settings, especially flow rate, should be reviewed and tunned more precisely.

(Image: 3DWithUs)

SainSmart TPU Filament Review – Shiny and Transparent TPU

TPU – Thermoplastic Polyurethane

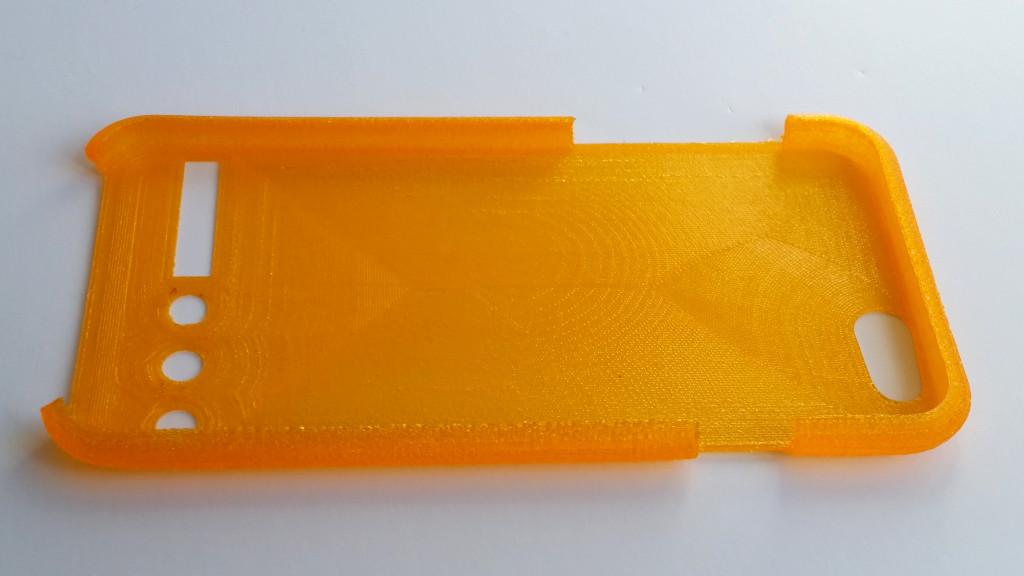

SainSmart TPU filament comes in a number of amazing colors. It doesn’t need high temperature to flow well. This material is great for making mobile phone cases. There is a wide range of printable files on STL sharing websites. While experimenting, we printed one case upside down with supports, to see what it would look like. Supports were hard to remove, but the result was very interesting, like in the picture below. We could not immediately think of any use for the thin membrane that supports created. However, it might be useful in some designs.

– Temperature. The recommended 3D printing temperature is 200 – 220°C and 40 – 60°C for the build plate. We achieved the shiniest result when 3D printed in a vase mode with a 0.8mm nozzle at 230°C. The filament fused so well that the walls came out transparent. It is possible to see the object through the walls.

(Image: 3DWithUs)

Sainsmart TPU Flexible Filament on Amazon (affiliate link)

– Spools. The only drawback we had with this filament is the filament spool design. Previously, SainSmart shipped their product on small unusual spools which were tricky to setup for most of our 3D printers. A separate spool holder was required. Now, according to the images on Amazon they use standard spools.

NinjaFlex TPU Filament Review – Feels Like Rubber

We also tested NinjaFlex green semi-flexible material. There was a problem with the flow. First, we had too much material, then not enough. See mobile case pictures below. We had to change the extrusion multiplayer setting twice to get it right. 0.93 gave us the desired result. It could be a sign of inconsistent filament width.

(Image: 3DWithUs)

The green Flexible Octopus by DiabaseEngineer came out well, though cooling the top part is much recommended. Otherwise, melting may cause damage to the object. The finished item felt like hard rubber. Please mind the warping when printing delicate, fine details.

NinjaTek Flexible TPU Filament on Amazon (affiliate link)

Some materials, not just flexible filament, shrink more than others. Octopus’s legs are thin and they cool down quicker. That’s why they got detached from the printing bed. Stronger adhesive and higher bed temperature help in this situation.

(Image: 3DWithUs)

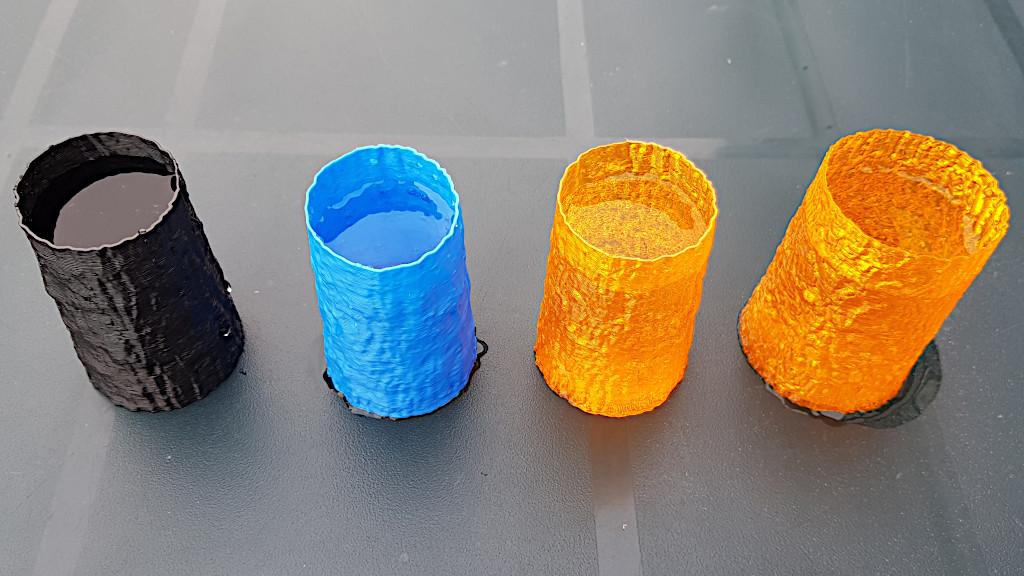

Filament PM RubberJet TPE 32 and TPE 88

TPE – Thermoplastic Elastomer

– RubberJet Collection. We had a chance to test the Filament PM test samples we received at the tradeshow. Filament PM has a decent variety of colors in their RubberJet collection. Some of the spools, marked as Shore 32 or Shore 88, are semiflexible and flexible respectively, the higher the number the softer the filament.

– Bed Adhesion. As manufacturers stated on their product page, there could be a problem with bed adhesion, and so they recommend using MAGIGOO PP GLUE STICK for the best result together with the following printing settings:

Nozzle Temperature – 220-240 °C

Bed Temperature – 0 °C

Speed – 10-20 mm/s

(Image: 3DWithUs)

And indeed, when we tried test samples, we made it right on the 3rd attempt only. While 3D printing on Original Prusa’s powder-coated spring steel sheet, we had our print bed at 100 °C, prepped with Pritt Power Glues Stick, and fan speed at 0.

We are not sure, yet, if this is due to the specific TPE properties as we didn’t have such a problem with TPU filaments.

– Smell. Black RubberJet TPE 32 is odorless while Blue RubberJet TPE 88 has a strong rubber smell.

Overall, we are very impressed with Blue RubberJet TPE 88. It is a very soft material indeed. The filament fused so well that our make could hold water after 3D printed in vase mode.

Flexible Filament requires certain skills and a good knowledge of your machine. Not all objects can be printed in flexible material. For example, joint parts designs that work well in PLA or ABS may require adjustment for flexible filament. Check our YouTube video below.

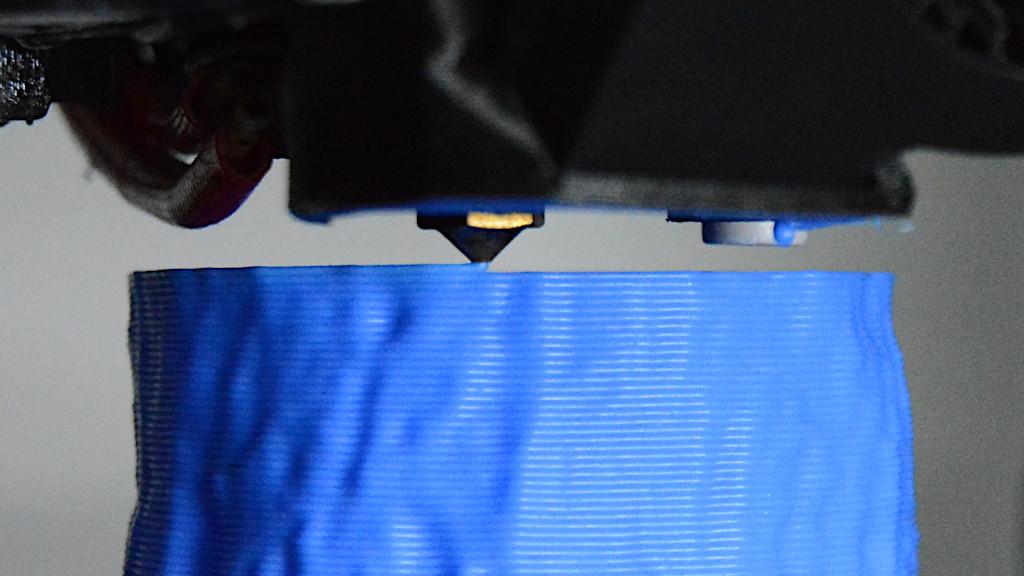

Vase Mode 3D Printing with 0.8 mm Nozzle

It is possible to achieve an astonishing result by 3D printing in both TPU and TPE in a Vase Mode using a 0.8mm nozzle. As we keep collecting tree scans, we experiment by editing and 3D printing these scans in all possible ways.

This time we used Monkey Puzzle’s and Redwood Giant’s tree trunk 3D scans to test vases for water tightness.

SainSmart Orange TPU, Filament PM RUBBERJet Blue TPE 32 and Black TPE 88.

(Image: 3DWithUs)

The 0.8mm nozzle and high temperature allowed to fuse the layers so well that all four prints could hold water. The objects are not completely waterproof, and after some time water will find its way out, but it may take hours or days.

What to 3D Print in Flexible Filament?

– Mobile Phone Cases. We 3D printed a few mobile cases and they came out nicely. There are a lot of STL files available on file repositories.

– Rubber Toys. We used flexible filament for the articulated flexi toy models. It is harder to get the slicing settings right as an excessive stinging may happen. The articulated slugs by 8ran (Remix by Skaart) in the picture below came out extra flexible in such filament.

(Image: 3DWithUs)

– Event Props. Cobweb, for example. Flexible poison-green cobweb 3D printed in Ninjaflex came out nicely, much better than in PLA.

– Tyres. For RC cars.

– Impact Hit Resistant Designs. All sort of protective items, including doorstops. Cheese wedge doorstop came out very well in SainSmart TPU.

Read More & Compare: 3D Printing Filament for Desktop 3D Printers

It is important to use the right 3D printer filament material for the right job. Here you can find the list of materials available together with detailed reviews and picture galleries for the most used materials in desktop 3D printing. PLA, ABS, Wood, PETG, Nylon, Support, TPU, etc. … Read More

Source & STL files

Anniversary Roses by XYZWorkshop.

Samsung Galaxy s5 Soft Case by Infernex87.

Flexi-Facehugger by ONEIDMONSTR.