The ACMER P2 33W Laser is one of the latest offerings from ACMER, a brand renowned for pioneering advancements in laser technology. ACMER has steadily built a strong reputation within the laser engraving community. This marks my third ACMER laser review, following the impressive P1S Pro 6W and P1 10W models. The P2 33W features a 420mm x 400mm engraving area, expandable by 200% with an optional kit, and offers blazing-fast engraving speeds of up to 30,000mm/min on industrial-grade X/Y linear guide rails. With six safety layers and a 30L/min air assist unit included as standard, this laser engraver is designed for high precision, safety, and versatility. In this review, I explore the 33-watt version, and test it by cutting and engraving on various materials. In conclusion, I will share my final thoughts and list of pros and cons.

Disclaimer: Laser cutting and engraving may be hazardous if improperly operated. Please make sure to follow the safety guidelines such as wearing eye-protective goggles and using the machine enclosure while operating.

Table Of Contents

- Specifications

- Unboxing and What’s Included

- Setup and Design

- Software

- Testing, Materials, Settings and Results

- Materials and Supplies

- General Material Settings

- Enclosure and Air Purifier

- Compare to other Laser Cutters and Engravers

- Conclusion and Pros & Cons

Price: $459 – $799

Product Affiliate Links: 3DWithUs is supported by its audience. Purchases via some links may earn us a small commission at no extra cost to you. This helps us to continue bringing you high-quality content. The product featured was provided in exchange for an honest review. Our guides and reviews remain unbiased and independent.

ACMER P2 33W Specifications:

Laser Power: 33W

Engraving Size: 420*400mm (16.54 × 15.75 inch)

Spot Size: 0.08×0.1mm

Engraving Speed: 30000mm/min

Main Board: ESP32 bit

Engraving Method: USB/APP/online/TF

Software Support System: Mac, Windows, Linux

Laser Wavelength: 445±5nm

Engraving Material: wood, plastic, paper, leather, bamboo, stainless steel, chevron, acrylic, glass, etc.

Engraving Mode: image engraving/text engraving/scanning engraving/convex engraving

File Format: SVG, NC, BMP, JPG, PNG, GCODE, etc.

Support Software: LaserGRBL, Lightburn

Safety Protection: emergency stop switch, anti-tilt device, power safety lock, flame detection

Product Weight: 6.5kg

Package Weight: 12.6kg

Product Size(L x W x H): 600*650*170mm

Package Size(L x W x H): 670*720*180mm

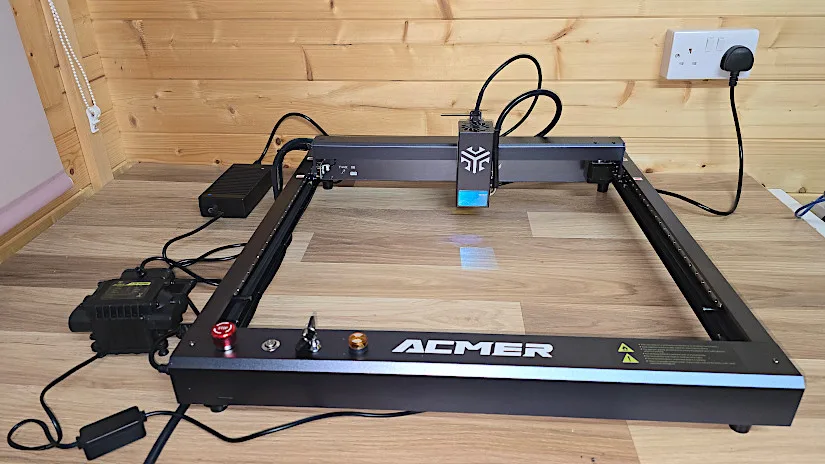

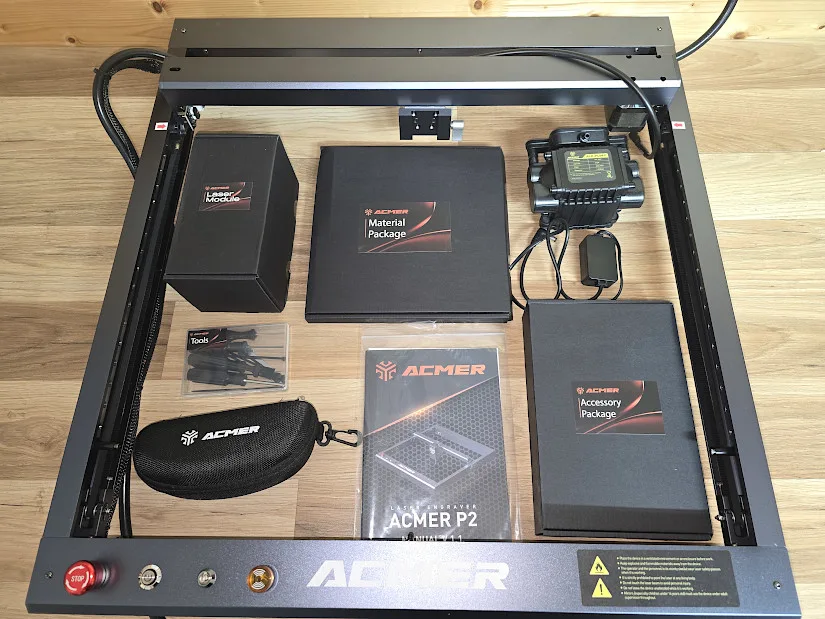

Unboxing and What’s Included

Pre-assembly Machine, Laser Module, Air Pump, Power Adapter, Machine Key, Laser Goggle, Card Reader, TF Card, USB Cable, 5x Test Plank, Metal Card, Acrylic Sheet, Cork Coaster, Wrench, Screwdriver, Brushes, User Manual.

©3DWithUs – Photo: Phil Macey

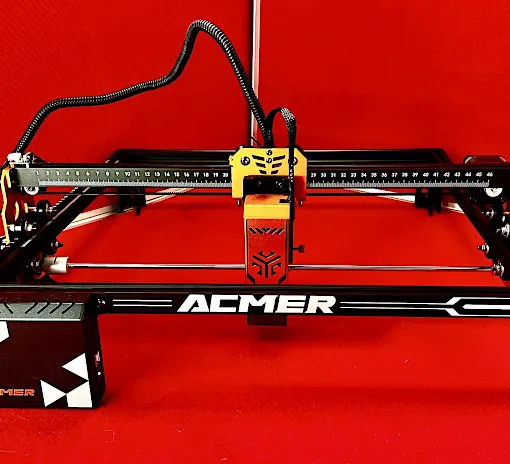

Setup and Design

The structural frame of the ACMER P2 laser engraving machine is made entirely of metal, enhancing stability and durability. The machine features a modular design and comes 95% pre-assembled, making installation quick and easy – just one minute. With only three simple steps, you can achieve full assembly:

1. As shown below, the laser module slides into the unit’s module housing, followed by connecting the integrated air line and power connections. Use the included cable tie for cable management.

©3DWithUs – Photo: Phil Macey

2. Connect up air assist to the underside of the laser unit located below the on/off button, as seen below.

©3DWithUs – Photo: Phil Macey

3. Connect up main power unit, and ensure all cables are clear of the engraving area.

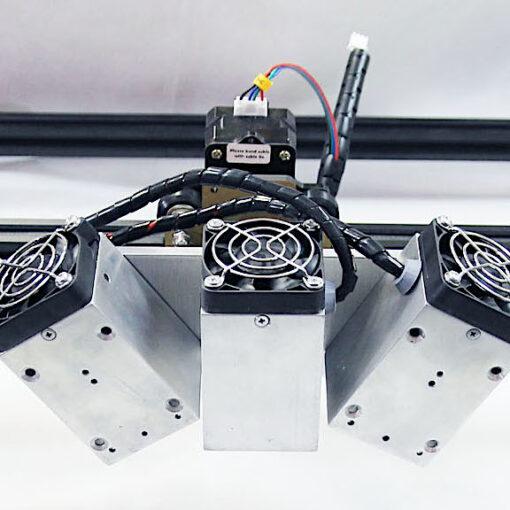

– Laser Module. With its powerful 33W diode laser, the Acmer P2 can handle cutting projects such as plywood (up to 30mm), acrylic (25mm), and MDF (8mm). Over 200 materials have been tested on each machine, showcasing the laser’s extensive capabilities. The 33W model features a laser focal point of 0.08–0.1mm, with a quoted lifespan of approximately 8,000 hours of use. Users also have the option to swap out the laser module for lower-rated versions, such as the 10W or 20W models, and can further enhance functionality by adding the 2W IR laser module. As shown below, the module includes two spare lenses and computer connection accessories.

– Air assist unit. The ACMER P2 laser also features an air assist unit, as shown below, which comes standard with this unit and connects directly to the laser, eliminating the need for additional plugs. The air assist improves the quality of the cutting and engraving process, along with a honeycomb bed to allow for good airflow. However, the honeycomb bed is available for purchase at an additional cost.

©3DWithUs – Photo: Phil Macey

– Supplied Materials for Testing. As shown below, ACMER has provided a diverse range of materials for testing before moving on to more advanced projects. My review will focus on these materials and their results.

• 1 x 2mm plywood sheets

• 2 x 7mm plywood sheets

• 1 x 3mm acrylic sheet

• 1 x Stainless steel square

• 1 x Anodised business cards

• 1 x Cork mat

©3DWithUs – Photo: Phil Macey

©3DWithUs – Photo: Phil Macey

– Safety Features. As shown above, the ACMER P2 is equipped with extensive safety features, including flame detection, an observable shield on the laser module, alarm lights and buzzers, a child safety lock, an emergency stop button, and a gyroscope tilt detector. However, it is strongly advised never to leave the laser unattended.

In my unboxing video above, I show how effortlessly this compact laser handles crafting projects while maintaining a focus on safety.

Software

Once the assembly is complete, the next step is to install the software. You can use Lightburn, Laser GRBL, or both, depending on your preference. The included TF card provides all the necessary files for setting up Laser GRBL and Lightburn, as well as Wi-Fi or wired connection options, cut patterns, and user guide files.

To streamline the setup, load the machine’s settings onto Lightburn using the supplied .lbn file. This made the setup process seamless and efficient.

Testing and Results

In this section, I will demonstrate the range of materials that the ACMER P2 33W laser can cut and engrave using the supplied materials, showcasing the results it can achieve. The machine also supports the addition of a rotary tool, which can be easily activated using a simple switch located at the rear of the unit, as shown below. However, since the rotary tool was not included, it will not be featured in this article.

Project 1 – 2mm Plywood Cutting and Engraving

Using the Lightburn test program, I created a file to evaluate the cutting capabilities of the ACMER P2. The results, shown below, demonstrate the range of cuts achievable in a single pass. With the air assist turned on, the optimal settings were between 70% power at 800mm/min speed and 100% power at 1100mm/min speed. The test was successful, showing excellent results.

©3DWithUs – Laser Job and Photo: Phil Macey

Project 2 – 7mm Plywood Cutting and Engraving

For this test, I added the ACMER name as a text file in Lightburn and used an engraving speed of 12,000mm/min. I then created a border in Lightburn to cut at 250mm/min speed, and 100% power with the air assist turned on. The results, shown below, are flawless, with no scorching or missed cuts, highlighting the machine’s versatility in cutting power and speed.

©3DWithUs – Laser Job and Photo: Phil Macey

Project 3 – Stainless Steel Engraving

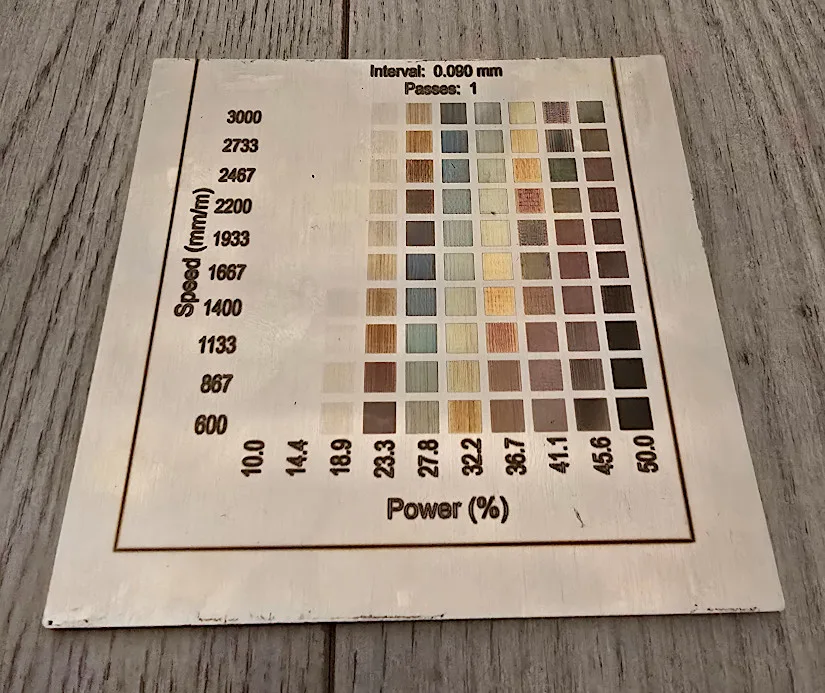

For this test, I created a laser test file in Lightburn, varying the power from 10% to 50% and the speeds from 600mm/min to 3000mm/min. The test took approximately 15 minutes to complete, and the results were impressive, demonstrating how power and speed variations produce different color schemes. This capability allows the laser to create stunning images with a range of colors, which is something I plan to utilize in the future.

©3DWithUs – Laser Job and Photo: Phil Macey

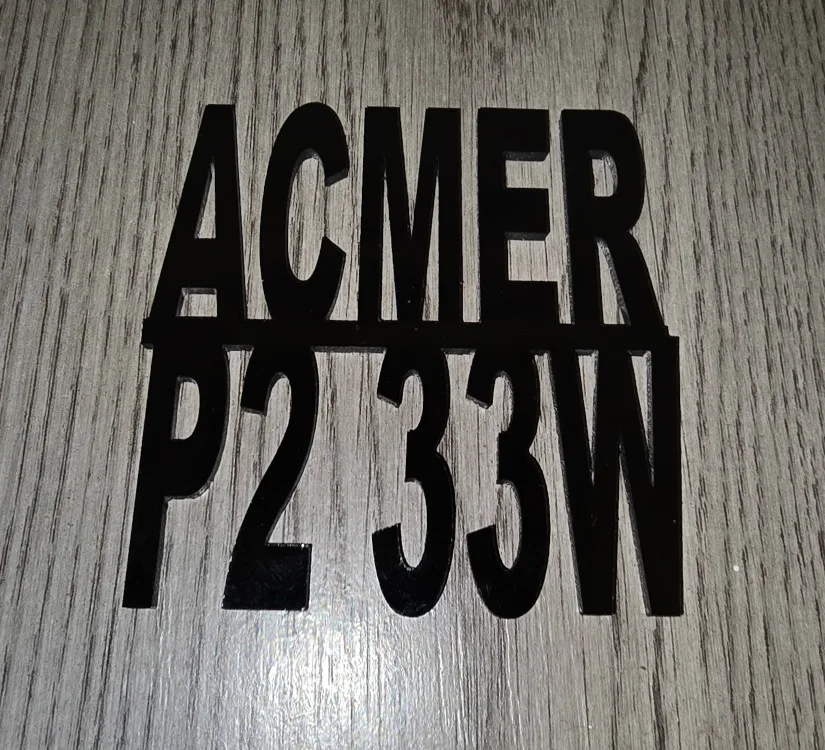

Project 4 – 3mm Black Acrylic Cutting

For this test, I created a text file with ‘ACMER P2 33W’ and set the speed to 200mm/min at 100% power with one pass and the air assist turned on. The process took approximately 3 minutes to complete. Since this was black acrylic, there was no need to pre-cover the test piece, as is often required with clear acrylics. To prevent scorching, I left the protective paper covering on during cutting. As shown below, the results were once again successful, with no burns or missed cuts. I believe that with multiple passes, it could cut through anything up to 25mm thick.

©3DWithUs – Laser Job and Photo: Phil Macey

Project 5 – Anodised Aluminum Engraving

For this test, I added the ACMER name and logo to Lightburn, setting the speed to 15,000mm/min at 100% power with 1 pass. I also adjusted the line interval to 0.0900mm to ensure a clean and precise image. The engraving took approximately 1.5 minutes to complete, and as shown below, the results were once again flawless, producing a clean and professional look. Some debris, often observed when engraving this type of material, required cleaning afterward.

©3DWithUs – Laser Job and Photo: Phil Macey

Project 5 – Slate Stone Engraving

For my final test, I chose to use a slate coaster, which was not included in the materials pack. However, since slate is a commonly used material for engraving, I wanted to test the machine’s capabilities with it. I set the speed to 9200mm/min at 100% power, with the air assist turned on. The engraving took approximately 5 minutes to complete, and the results were once again outstanding.

©3DWithUs – Laser Job and Photo: Phil Macey

Custom engraved slate stone coasters can make wonderful gifts. The ability to engrave on such materials demonstrates the versatility of laser engravers. The ACMER P2 33W can easily handle such tasks, showcasing its competitive performance. On 3DWithUs, we have a detailed guide on laser engraving on stone-like materials.

Materials and Supplies

I was pleasantly surprised to find a vast collection of materials and supplies for laser engraving on the ACMER website. I haven’t had a chance to try them, but I feel they are worth a look.

Material Settings for ACMER P2 and Other Series Machines

I referred to the material settings tables on the ACMER website for guidance on adjusting the settings. These tables provide a list of all materials along with their respective settings for laser cutting and engraving. Key settings to keep an eye on include material thickness – especially important when cutting-laser power, speed, and the number of passes.

Optional – Enclosure and Air Purifier

Two highly recommended optional items I haven’t had a chance to test are the Enclosure and Air Purifier. Both are essential when laser cutting is involved. Even a 6W laser can be dangerous if operated incorrectly. An enclosure helps create a controlled and protected environment, while an air purifier manages excessive smoke.

Compare ACMER Laser Engravers and Cutters

On the ACMER website, the P1 S Pro 6W is the most budget-friendly option, with many optional add-ons available. In addition to the P1 series, the P2 and P3 series machines are also available for purchase, featuring more powerful lasers and advanced specifications.

An innovative laser product, the ACMER P3 comes fully enclosed with IR and diode dual laser engraving and cutting capabilities. For the full range of ACMER laser cutters and engravers, please check the official website.

On 3DWithUs, we have featured a few compact portable laser cutters and engravers that operate with diode lasers. For a comparison please refer to the detailed Best Laser Cutters and Engravers Guide.

On our website, you can compare the prices, capabilities, and functionalities of laser engravers and cutters from brands such as xTool, Snapmaker, LaserPecker, and others. What distinguishes the ACMER P2 33W is its high-quality build and competitive pricing.

©3DWithUs – Laser Job and Photo: Phil Macey

Conclusion and Pros & Cons

ACMER P2 33W Review

Review Summary

During my testing of the ACMER P2 33W laser, several features stood out. The laser’s 0.01mm focal point, premium build quality, extensive safety features, and supplied air assist make it an exceptional product. Additionally, the ability to swap the laser module for varying outputs, such as 10W, 20W, or the 2W IR laser, adds incredible versatility, making the ACMER P2 33W laser a must-have for both home crafting and business needs.

The machine prioritizes safety with features such as the gyroscope tilt detector, which stops the laser if tilted, and a flame detector to monitor for fire risks. Combined with other safety features mentioned earlier in this review, the ACMER P2 ensures a safe and controlled work environment.

With a working area of 420mm x 400mm, the laser accommodates large projects, which can be further expanded by 200% with the optional expansion pack. The ACMER P2 achieves impressive speeds of up to 30,000mm/min, thanks to industrial-grade linear rails on the X and Y axes.

The ACMER P2 33W laser supports crafting with over 100 materials, offering endless creative possibilities. Whether for intricate designs or larger-scale projects, this laser delivers exceptional results.

Overall, my experience with this laser has been nothing short of amazing and enjoyable. It has become one of my standout lasers of 2024, earning its title as the best laser engraver of the year – a title it truly deserves. I am excited to continue using it for crafting projects in 2025.

The extensive capabilities of the ACMER P2 far outweigh its cost, making it a fantastic investment. My unboxing video below highlights how effortlessly this laser handles crafting projects, making it an enjoyable and safe experience for the whole family.

Pros

- 30,000mm/min laser engraving speeds

- Exceptional engraving and cutting quality

- Multiple diode power rating options

- Six safety features, including tilt detection

- Wi-Fi enabled for seamless connectivity

- Industrial-grade linear rails for precision

- Expandable engraving area with optional attachments

Cons

- No enclosure included, but available as an additional purchase

- Limited ability to adjust air assist flow