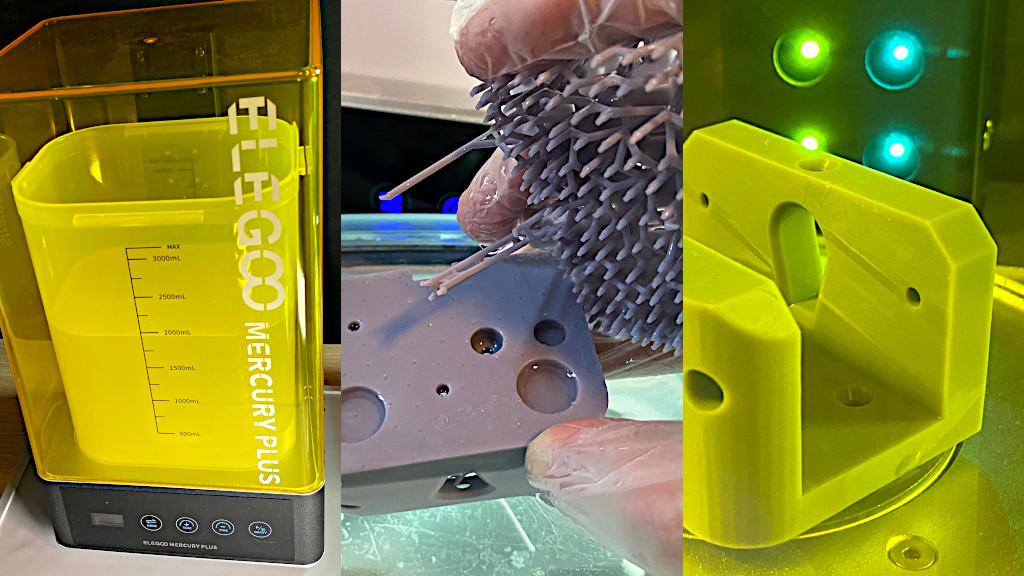

If you’ve used a DLP, MSLA, or SLA resin 3D printer before, you’ll immediately understand the appeal of the Elegoo Mercury Plus, a standalone machine which combines wash and UV cure stages into a single unit. Using a resin 3D printer can be a messy process, and the post-processing steps can turn even the cleanest desk into a sticky mess as photopolymer resin, isopropyl alcohol, and other cleaning fluids are used in the printing process.

Print, Wash, and UV Cure

The Elegoo Mercury Plus is a standalone unit that is an ideal companion for resin 3D printers and creates a simplified workflow that can reduce the amount of mess involved in the printing process. This workflow can be broken down into three parts: print, wash, and cure. Just as with resin 3D printing, having a well-ventilated workspace is important to avoid eye or skin irritation from the photopolymer and the isopropyl alcohol.

Product affiliate links:

Amazon

Official Website

For a comparison with other machines, please refer to the detailed Washing and Curing Stations Guide.

(Photo: Andrew Sink)

Preparing Parts for the Wash and UV Cure Box

When an object is printed on the Elegoo Mars 2 Pro, the build platform and the printer are both coated in liquid resin, a byproduct of the vat printing process. This means that the parts are not yet safe to touch, despite the printing stage of the process being complete.

(Photo: Andrew Sink)

Before the Elegoo Mercury Plus

Before placing the part in the Mercury Plus, the parts should be angled on the printer to allow excess resin to safely drip back into the vat for later use. Once the parts have drip-dried, they are ready for the resin removal “wash” stage of the process.

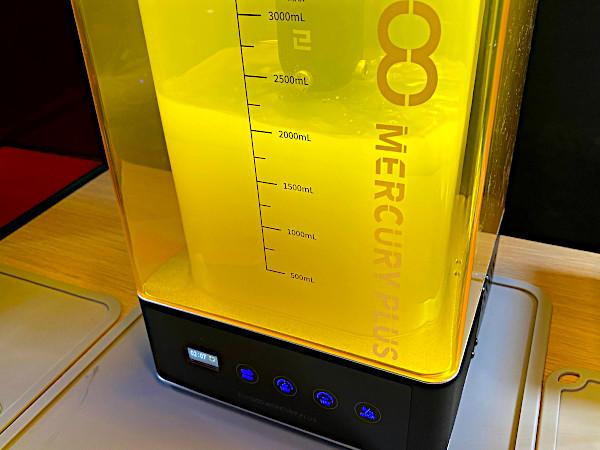

The Mercury Plus includes a resealable container that holds up to 3 liters of isopropyl alcohol for rinsing the parts. There is also a mount which allows the full build plate to be suspended in the machine for washing.

(Photo: Andrew Sink)

Running the Wash Cycle – Isopropyl Alcohol

The Mercury Plus uses a magnetic stirrer built into the base of the unit to spin a plastic impeller inside the wash container. This causes agitation in the cleaning fluid and actively rinses both the part and the build plate simultaneously. I used 70% Isopropyl Alcohol on Amazon as the current shortage of 91%+ has made it nearly impossible to find, and the 70% has worked for me in the past for cleaning resin parts. The direction of the impeller changes during the cycle, which keeps the resin from pooling in any corners of the part. The Isopropyl Alcohol breaks down the uncured resin and removes it from the surface of the part as well as the inside of the part if it has been hollowed out.

Why Wash Your Resin Print?

When printing with a resin 3D printer like the Elegoo Mars, the MSLA process will cure the resin that is exposed by the UV light source, but will leave the rest of the resin in the vat unpolymerized. This resin is not something you want to handle, and the part is effectively submerged in it for the duration of the printing process.

The resin removal process typically involves transferring the part and build plate to a progressive series of “cleaner” containers in an effort to remove the resin, similar to how a commercial dishwasher works. By using a single large container in which the part and build plate can be submerged, the overall amount of excess resin is dramatically decreased without requiring any direct handling of the part.

(Photo: Andrew Sink)

Rinsing the Washed Part

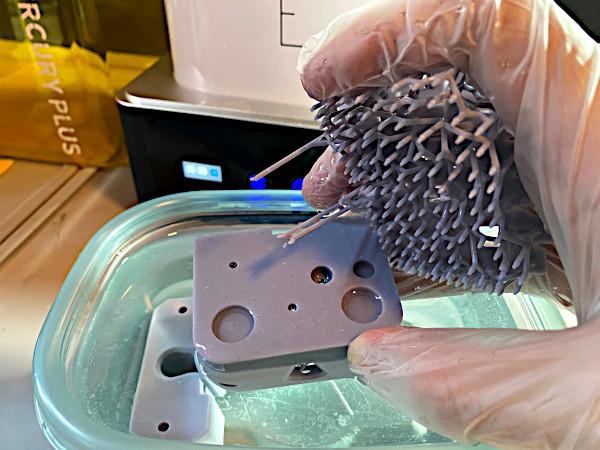

The wash stage of the Elegoo Mercury Plus removes most of the resin that is on the surface of the model, but some may remain trapped inside or stuck in fine features or details. Once the part has been washed, it can be rinsed off in a small container with tap water to get off any resin that was still stuck and break off the support material.

This is a slow and gentle process, as the part is still uncured and is slightly tacky to the touch and can be scratched or dented without much force. Using warm tap water while wearing thin vinyl gloves allows the support structure to be removed easily from the part without exposing your skin to any uncured resin.

(Photo: Andrew Sink)

Running the Resin UV Curing Cycle

Once support is removed and the part has been rinsed, the included wash container is removed from the machine and a small plexiglass turntable replaces it. After placing the rinsed part on the turntable, the “cure” stage of the process can begin. The amount of cure time varies with different resins, but the intervals are again selected in 30 second increments on the touch screen. The Mercury Plus has a stand that contains eight 385nm LEDs and eight 405nm LEDs which are used to fully cure the exposed resin on the surface of the part. A nice safety feature of the Mercury Plus is that the UV LEDs will not activate unless the lid is secured, which helps prevent accidental UV exposure to the user.

(Photo: Andrew Sink)

The rotating turntable allows the UV LEDs to cure all exposed surfaces, but the part needs to be fully rotated at least once to make sure all surfaces are uniformly cured. This means an object should be placed on its side to allow the top and bottom to be exposed for full and uniform coverage.

Should You Buy the Elegoo Mercury Plus?

The Elegoo Mercury Plus can usually be found available for around $149 online, and goes on sale from time to time for even less. Personally, I think this machine is a bargain and absolutely worth every penny. Cleaning resin parts can be a messy and difficult process that leaves a surface covered in sticky resin and rubbing alcohol, but the Mercury Plus enables users to have a single solution that can solve their post-processing problems.

Product affiliate links:

Amazon

Official Website

By using the clever solution of a magnetic turntable, the Mercury Plus is able to switch from wash stage to cure stage by simply removing the container of cleaning fluid and placing the acrylic turntable in the machine. This means the need for multiple buckets of fluid is eliminated, as well as the need for a separate UV curing chamber. If you own a resin printer and are interested in simplifying your post-processing setup, I would definitely recommend looking into the Elegoo Mercury Plus.

- Read More: Elegoo Mars 2 Pro Review by Andrew Sink

- Read More: Elegoo Mars Pro Review by Tessa Nesci

Read More and Compare: Best Wash and Cure Stations

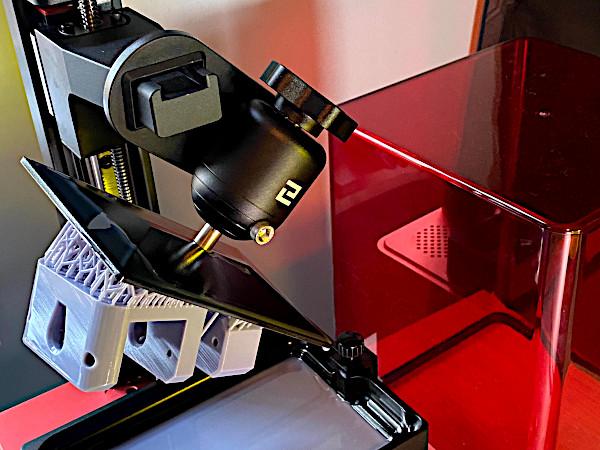

Post-processing is a big part of 3D printing in resin, and additional equipment, like wash and UV cure stations, is needed. In recent years, these two separate units started coming as two-in-one stations. Similar to 3D printers, washing and curing stations saw a few improvements with time, which made them more efficient with a better user experience. …

Read More & Compare

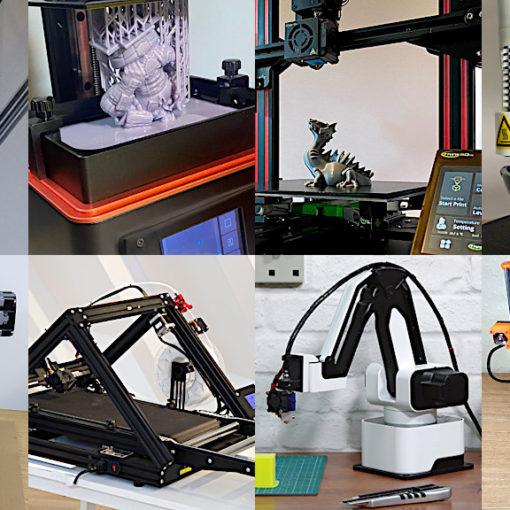

Read more about desktop 3D printer builds and processes. Type, volume, FDM or Resin, all to consider. Or jump to the latest 3D printer reviews.

For a comparison with other resin 3D printers please refer to the

detailed resin 3D printers guide.