The Elegoo Centauri Carbon is a fully enclosed CoreXY 3D printer designed for high-speed, high-temperature printing at an affordable price. In this hands-on overview, we explore its setup, key features, slicer workflow, and print results. With a sturdy frame, auto calibration, and practical extras like a dual-sided PEI plate and onboard camera, it stands out in the sub-$300 category. A detailed summary with Pros and Cons is included at the end.

Update 28.01.2026: It has been officially confirmed that the Centauri Carbon’s multicolor system is still under development and optimization.

Table of Contents (Jump to a Section)

- Elegoo Centauri Carbon Specifications

- What’s in the Box

- Design and Features

- Unboxing and Setup

- Software – Elegoo Slicer Settings

- Test Prints and Results

- Compare Elegoo Centauri Carbon to Other 3D Printers

- Conclusion and Pros & Cons

Where to Buy the Elegoo Centauri Carbon

Price: $299

We don’t know if this product will be available on Amazon or other major e-stores, but just in case, here is the link to their Amazon store.

Elegoo Centauri Carbon Specifications

• Printing technology: FDM (Fused Deposition Modelling)

• Print volume: 256 mm × 256 mm × 256 mm

• Printer Dimensions : 398 mm x 404 mm x 490 mm

• Extruder type: Direct drive

• Nozzle diameter: Standard 0.4 mm

• Printing speed: Up to 500 mm/s, standard 300 mm/s

• Filament Diameter: 1.75 mm

• Maximum Extruder Temperature: 320 °C

• Heated Build Plate Temperature: up to 110 °C

• Maximum Print Speed: 500 mm/s

• Maximum Acceleration: 20,000 mm/s

• Layer Thickness: 0.1 – 0.4 mm (Recommended 0.2 mm)

• Connectivity: USB, WIFI

What’s in the Box

Centauri Carbon printer •Textured PEI build plate •Lid •Allen keys • Screwdrivers • nozzle cleaner •USB drive •Glue Stick • Grease •Touch screen •Filament sample • Power cable • User manual

©3DWithUs – Photo: Phil Macey

Design and Features

The Elegoo Centauri Carbon is a compact, enclosed CoreXY 3D printer engineered for speed and material flexibility. Its build and feature set are aimed at users who want a faster workflow while benefiting from the environmental control that an enclosure provides.

Enclosure and Frame

The printer features a rigid, die-cast aluminium frame with SPCC steel side panels and tempered glass doors and lid. This fully enclosed design helps stabilize internal temperatures, reduce warping, and improve print consistency, especially when printing ABS, ASA, or nylon-based materials. A removable glass top lid allows better ventilation for lower-temperature materials like PLA or PETG.

Build Volume and Movement System

The Centauri Carbon offers a cubical build volume of 256 × 256 × 256 mm, supported by a CoreXY motion system. The design enables high-speed movement with reduced vibration. Elegoo specifies a top print speed of 500 mm/s and acceleration up to 20,000 mm/s², although typical use will be slightly slower for quality prints.

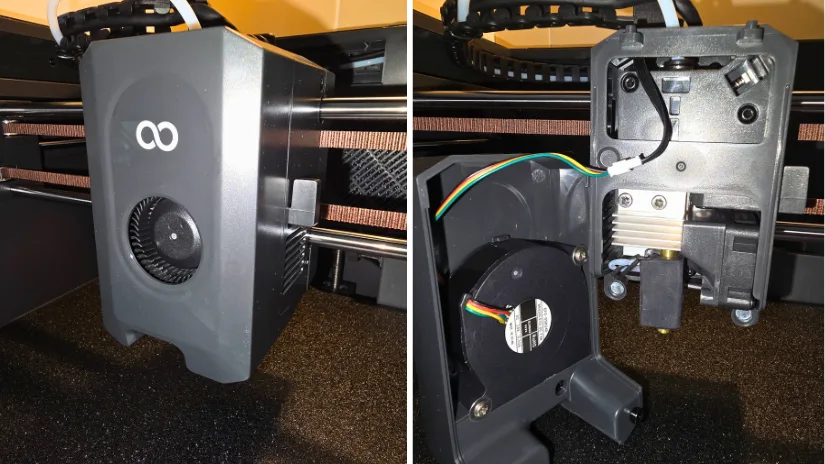

Extruder and Print Head

The printer uses a direct drive extruder with dual hardened steel gears to handle flexible and abrasive filaments. It’s paired with a 60W ceramic heater capable of reaching 320°C, and a 5020 part cooling fan for efficient heat dissipation during high-speed jobs.

The extruder housing is magnetic and opens easily for access to the hotend and internal parts—making nozzle swaps and maintenance straightforward.

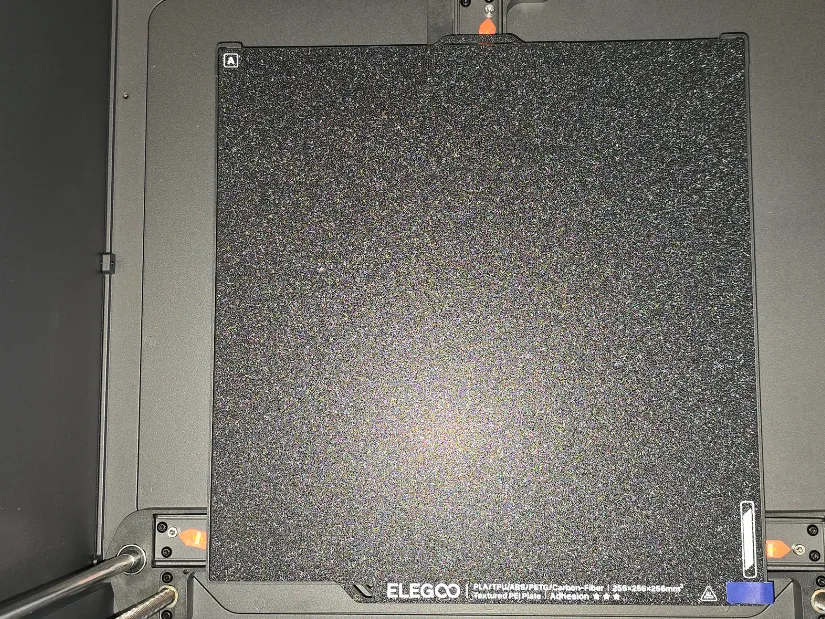

Heated Bed and Surface

The 1000W AC heated bed reaches up to 110°C, improving adhesion and enabling the use of engineering-grade materials. It ships with a dual-texture PEI spring steel build plate—one side textured (for materials like PETG and TPU) and the other smooth (ideal for PLA and fine-detail prints).

Internal Camera and Lighting

The printer includes a built-in camera and LED light, allowing real-time monitoring and basic time-lapse functionality via a local web interface. While there’s no dedicated Elegoo app for remote access yet, the web interface can be used through a browser on the same network.

Additional Features

– Automatic Z-axis testing before every print for first layer accuracy

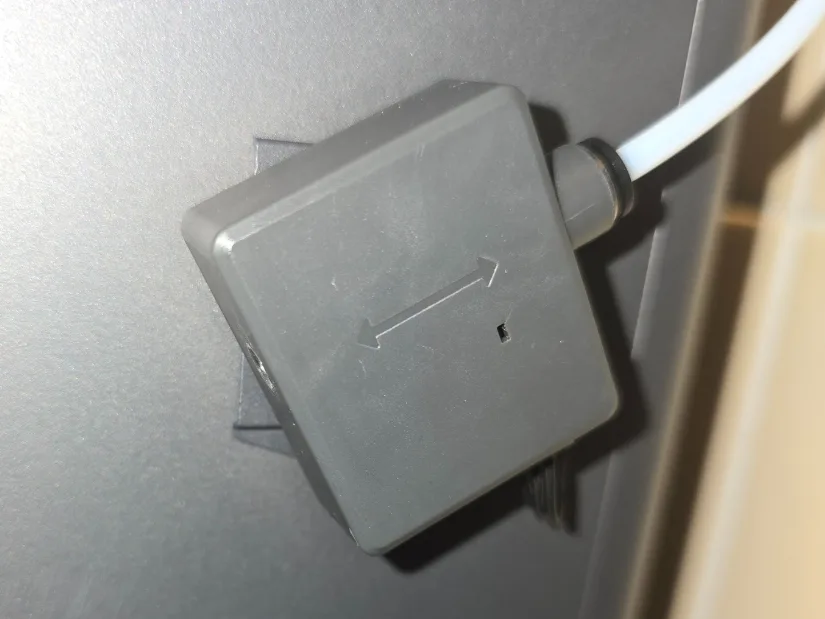

– Filament runout sensor mounted externally for easy access

– 4.3-inch color touchscreen with multilingual interface

– Filament waste chute and nozzle wiper for cleaner starts

– Connectivity: Wi-Fi and USB options

A practical touch is the inclusion of printable utility models on the USB drive, such as a lid holder that mounts to the side of the machine using existing screws—helpful when running open-top prints.

Unboxing and Setup

The Elegoo Centauri Carbon ships largely pre-assembled, making the setup process straightforward even for users who are new to CoreXY machines. Most components are securely fastened inside the enclosure with transit protection in place.

After unboxing, a few basic steps are needed before powering on the printer. These include removing the protective foam inserts, cutting the cable ties, and unscrewing the three transport screws that hold the build plate in place. The filament holder can be attached to the right-hand side of the unit using the supplied bracket. The touchscreen connects via a ribbon cable and locks into place before mounting. Finally, the power cable is plugged into the back of the printer.

Once powered on, the touchscreen will guide you through the rest of the process. This includes selecting your preferred language, setting up Wi-Fi (which can also be done later), and initiating the calibration routine.

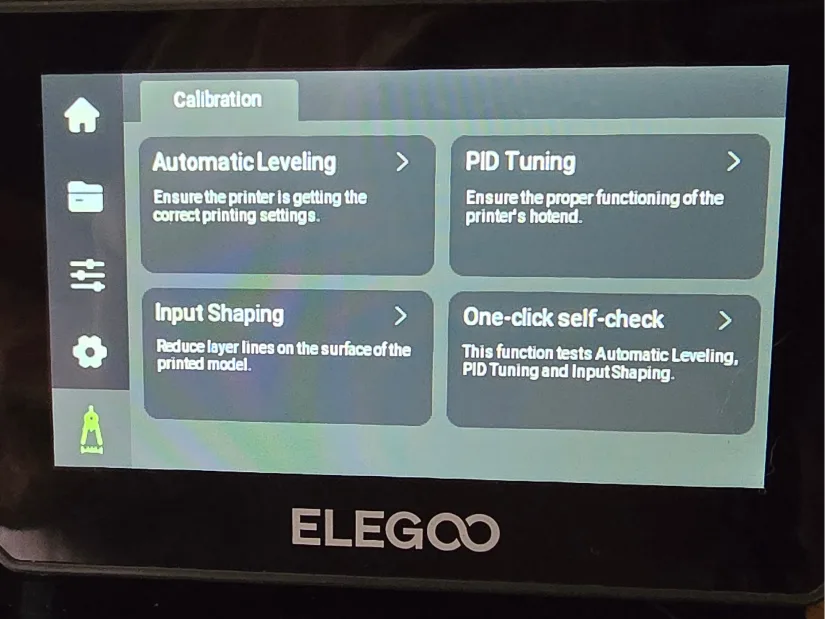

Calibration

The Centauri Carbon features an automatic calibration system. It performs full auto bed leveling using four pressure sensors combined with Elegoo’s built-in algorithm. The Z-offset is calibrated during this process, followed by vibration compensation and pressure advance tuning. The full calibration typically takes 15 to 20 minutes to complete and can be restarted at any time via the touchscreen settings menu. Recalibration is also recommended after any firmware update.

Thanks to the enclosed structure, preconfigured firmware, and clear setup instructions, users can move from unboxing to printing within a short time.

– Watch: Elegoo Centauri Carbon hands-on overview: Elegoo Centauri Carbon assembly, feature breakdown, and test printing.

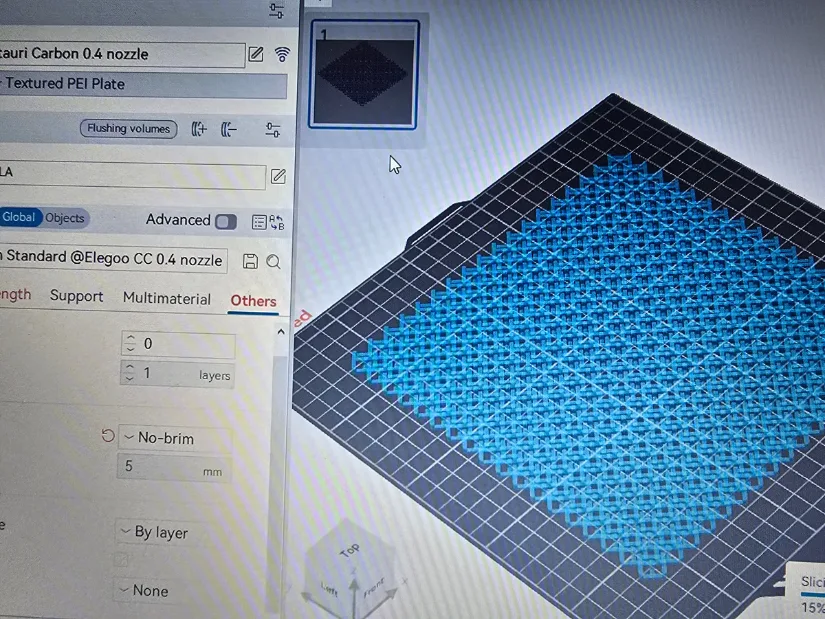

Software – Elegoo Slicer Settings

The Elegoo Centauri Carbon is compatible with the Elegoo slicer, which is based on the Orca engine with added presets and connectivity for Elegoo-branded machines. The slicer includes pre-configured profiles for the Centauri Carbon, helping users get started quickly without adjusting advanced parameters.

For this article, all prints were prepared using the default Centauri Carbon profile. Minor adjustments were made to optimize print speeds. In particular, inner wall speeds were set to 300 mm/s and outer walls to 250 mm/s to align with the printer’s high-speed capability while maintaining consistent quality.

The software provides essential features such as tree supports, ironing, variable layer height, and direct Wi-Fi file transfer to the printer when connected on the same network. Model previews and time estimates proved reliable during our testing, especially for multi-hour prints that covered most of the build plate.

For users more comfortable with alternative slicers like OrcaSlicer, it’s also possible to export G-code manually.

Overall, Elegoo’s slicer is easy to use and well-suited for both first-time users and experienced makers looking for quick integration with Centauri Carbon hardware.

Test Prints and Results

To evaluate real-world performance, we tested the Elegoo Centauri Carbon using a range of functional and decorative models. All prints were sliced using Elegoo Orca with the base Centauri Carbon profile, modified only slightly for speed and material consistency. The machine was tested using both Elegoo and third-party filaments, including dual-color silk PLA and engineering-grade spools.

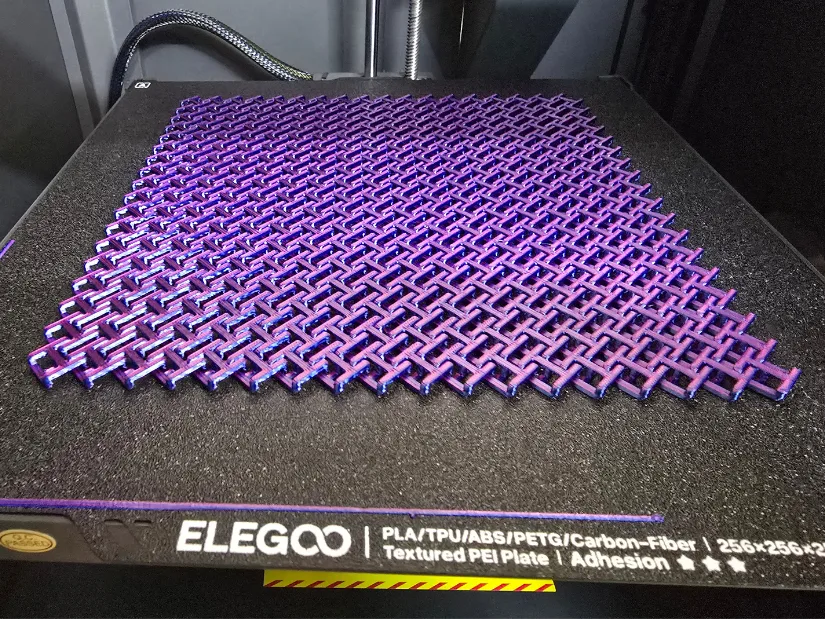

Model 1: Chainmail 3D Printable Fabric

Design by Agustin Arroyo – Printables

©3DWithUs – Print and Photo: Phil Macey

This flexible chainmail fabric measured approximately 20 × 20 cm and took around 4.5 hours to print using 0.2 mm layer height and 0% infill. Despite the model’s interlocking structure, all links printed cleanly without failures. The print covered a large portion of the build plate and highlighted the machine’s accuracy in motion and retraction control.

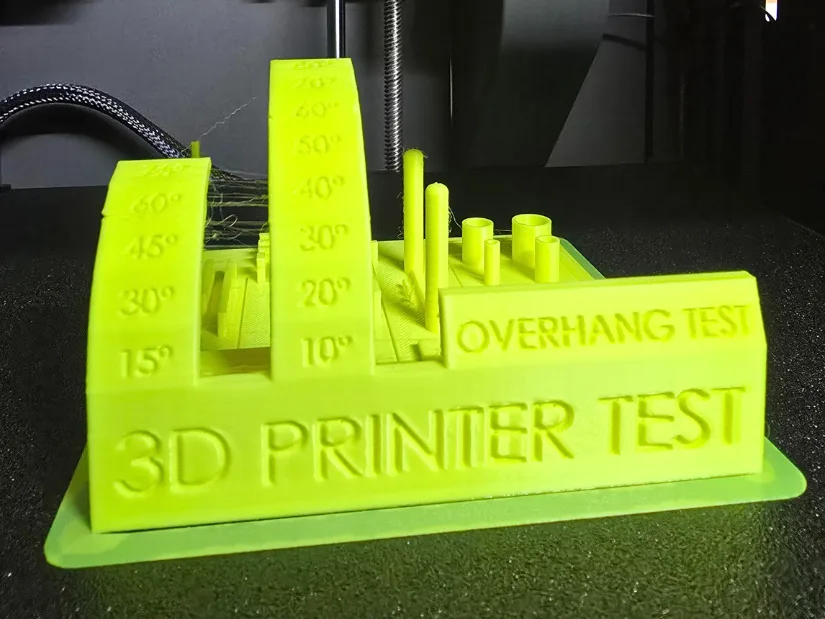

Model 2: All-in-One 3D Printer Test

Design by Gabbox3D – Printables

©3DWithUs – Print and Photo: Phil Macey

This compact print includes tests for bridging, overhangs, dimensional accuracy, stringing, and more. Printed in about 2 hours with a 0.2 mm layer height, the model showcased strong cooling performance and reliable motion planning. This test was completed using Eolas Prints neon green PLA from a spool picked up at the TCT 3Sixty show in the UK.

Model 3: Penny Bear

Design by Bugman_140 – Thangs

©3DWithUs – Print and Photo: Phil Macey

This character model took approximately 4.5 hours to print using a 0.2 mm layer height, 35% infill, and painted-on tree supports for floating sections. Printed with dual-color silk PLA, the result was clean and well-defined, showing smooth vertical surfaces and no support scarring. The model also highlighted reliable performance with moderate overhangs.

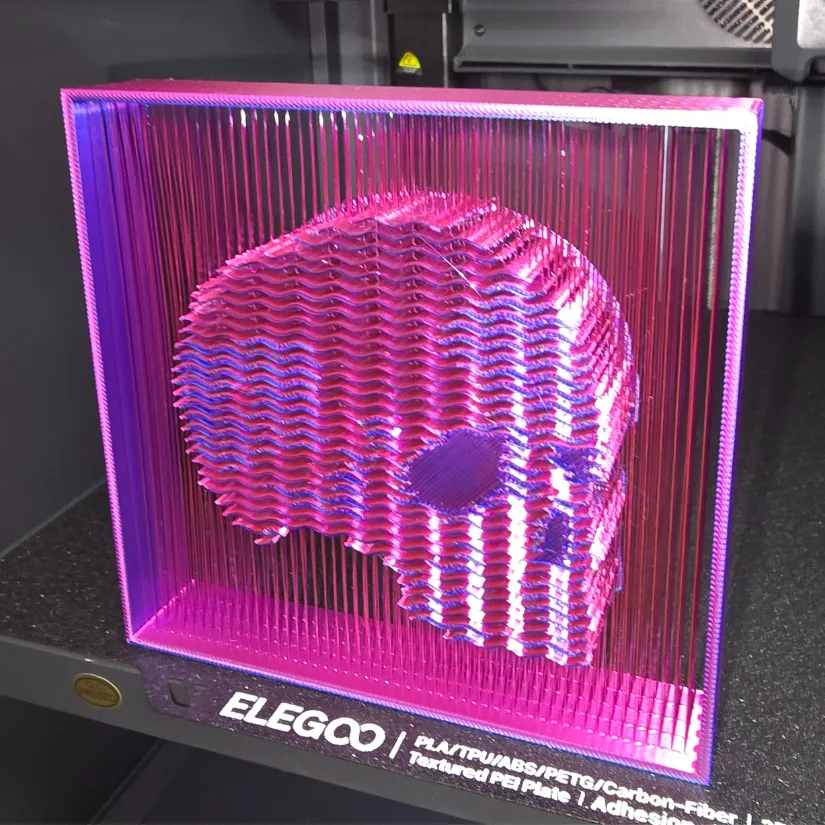

Model 4: Fragmented Skull String Art

Design by 3DPrintBunny – Printables

©3DWithUs – Print and Photo: Phil Macey

This print featured intricate bridging and fine walls, designed specifically to test slicer algorithms and cooling. Printed in 4 hours using 0.24 mm layer height and Arachne-based wall detection (no supports or brim), the model turned out clean and intact. The machine maintained print quality even with extended bridging distances and delicate details.

Across all test models, the Centauri Carbon delivered consistent layer lines and dependable adhesion on both sides of the PEI build plate. Print speeds remained high without major artifacts, and calibration remained accurate over time. These results support the printer’s positioning as a fast, enclosed CoreXY machine capable of handling varied print types out of the box.

Compare Elegoo Centauri Carbon to Other 3D Printers

The CoreXY segment continues to expand, with several brands now offering compact, enclosed machines focused on speed and material compatibility. The Elegoo Centauri Carbon enters the field with a sub-$300 price tag, enclosed frame, and sturdy CoreXY motion, making it a notable addition to our Best Budget FDM 3D Printers guide.

When compared to other CoreXY printers in this range, like the Anycubic Kobra S1, Bambu Lab P1S, or Creality K1, the Centauri Carbon stands out by offering many of the same core features at a lower entry cost.

It meets key performance specifications, including a 500 mm/s speed and 20,000 mm/s² acceleration, and features common high-speed capabilities such as auto bed leveling, input shaping, and vibration compensation.

©3DWithUs – Print and Photo: Phil Macey

Read more: Elegoo Centauri Carbon 2 Combo: Hands-On Testing and Results

Have questions? Feel free to ask in the comment section below.

For a wider discussion or to share your own Centauri Carbon prints, join us in the forum:

Conclusion and Pros & Cons

We don’t know when or if this product will be available on Amazon or other major e-stores, but just in case, here is the link to their Amazon store.

Elegoo Centauri Carbon Hands On

Review Summary

The Elegoo Centauri Carbon marks the company’s first step into the CoreXY FDM printer space. It promises fast printing speeds, solid build quality, and ease of use, and largely delivers on those claims. Setup was quick and straightforward. I was printing within 20 minutes of unboxing. The minimal assembly process and intuitive touchscreen interface make it accessible for beginners while still satisfying more advanced users.

Elegoo’s slicer software, preloaded with working profiles, performed well throughout testing. It makes a good starting point for newcomers while allowing experienced users to tweak settings as needed. Notably, the Centauri Carbon includes a dual sided PEI plate, with Side B optimized for PLA, offering flexibility without the need to swap sheets.

The printer also features a built in camera and lighting, useful for remote monitoring and timelapse recording via a web interface. While there is no dedicated Elegoo mobile app yet, access through a local browser works well. Another nice touch is the full auto calibration routine with no paper shimming required. The magnetic tool head housing makes maintenance easier. Additional features like a rear nozzle wiper and filament waste chute improve workflow. A mini version of the printer, preloaded on the USB stick, doubles as a waste bin.

From print quality to UI experience, the Centauri Carbon exceeds expectations for its price point. It is a strong debut in the CoreXY category, and it will be interesting to see if Elegoo expands the lineup, perhaps with a larger format or multi material compatibility in the future.

Update 28.01.2026: It has been officially confirmed that the Centauri Carbon’s multicolor system is still under development and optimization.