Visited a local model boat club on their open day. I got the chance to steer a model boat, chat with experienced members, and take a closer look at their impressive builds. Among the traditionally crafted models, one stood out: a 3D-printed RC trimaran, printed on a Creality Ender 3 V3. I left not only with great memories but also with a ‘Surfer’ RC boat, which I plan to customise using 3D printing. The visit sparked fresh inspiration on how digital tools and traditional modeling can complement each other.

This Guide Covers

- RC Model Boat Hobby

- Craftsmanship: Handmade vs. High-Tech

- 3D Printing’s Role

- Passionate Members

- 3D Scanning Boat Parts

- From Broken to a New RC Boat

- Conclusion

What Is the RC Model Boat Hobby? Southend MBC as an Example

The RC model boat hobby has been around for decades. It blends engineering, craftsmanship, and creative design with a strong social element. For example, each Sunday (and other days), enthusiasts gather at Southchurch Park in Southend-on-Sea, UK, to sail their boats, ranging from standardized sailing yachts to tugboats, mini fishing vessels, and custom trimarans. It’s a laid-back yet dedicated community, characterized by friendly competition, deep knowledge sharing, and a strong sense of pride in the models they build from scratch or put together from kits and operate.

Craftsmanship: Handmade vs. High-Tech

Most of the boats on display were traditionally built by proffesionals, using wood, fiberglass, and paint, painstakingly shaped and detailed by hand. The craftsmanship is incredible, with many boats replicating real-world designs down to the smallest details, including winches, rigging, and lights.

One boat featured obvious 3D printed components: a striking green RC trimaran, printed on a budget 3D printer Creality Ender 3 V3 by Peter Moffat, Fast Electric Secretary. It sailed smoothly, showcasing how 3D printing is slowly making its way into the scene.

Not all boats were handmade, though. Some, especially the high-speed models, appeared to use molded or factory parts – likely from mass-produced kits or commercial builds. It’s a diverse hobby with many approaches.

3D Printing’s Role in RC Model Boating

Where it fits now:

- Replacement parts (rudders, prop guards, hull brackets)

- Functional upgrades like hatches and holders

- Prototyping hulls or design concepts at smaller scales

Where it could go:

- Open-source or customizable boat kits shared on platforms like Printables or Cults

- 3D scanning existing boats to create miniatures or accessories

- Hybrid models that combine handcrafted hulls with 3D printed details

It’s still early days, but for makers who already own a 3D printer, RC boating opens up a new outlet for experimentation and fun.

Ask Passionate Members

One of the highlights of the day was chatting with longtime club members Andy and Clive. Their enthusiasm was infectious, and their collection of boats was both vast and varied. From historically inspired ships to functional working vessels. They were eager to share their knowledge of design, parts, and electronics. It was clear this wasn’t just a hobby – it was a passion.

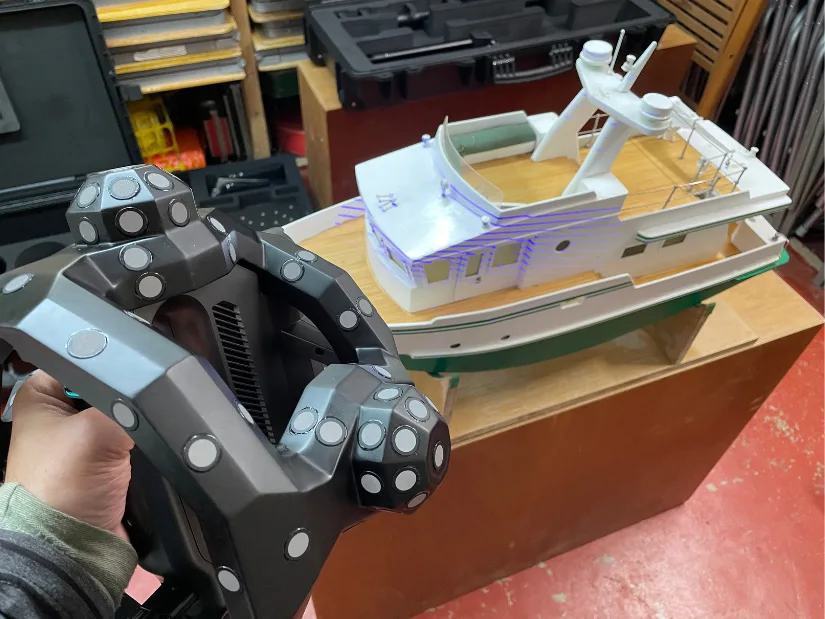

Update: 3D Scanning Boat Parts

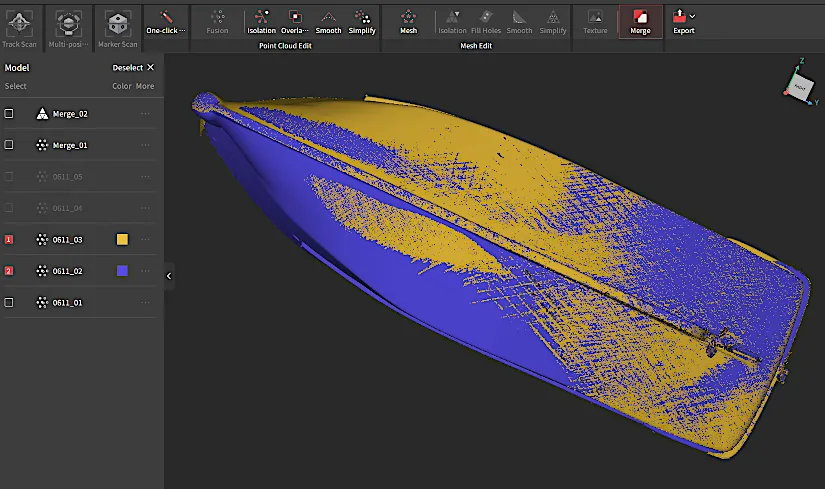

As part of testing the Revopoint Trackit — a marker-free 3D scanner — the club kindly allowed me to scan some of their boats. It was a great opportunity to test the scanner in a real-world setting. Transporting and setting up the equipment went smoothly. For my first scan, I chose the MILA boat, as its large, well-defined parts seemed ideal for capturing without complications.

According to Clive and Andy, the wasn’t performing well in windy conditions. The top was too heavy, and the hull didn’t sit deep enough in the water, making it unstable. That makes this case particularly interesting—3D scanning and 3D printing could be used not only to repair the model but also to optimize its design for improved speed and stability on the water.

Due to limited time, I didn’t plan to fully fix the boat, but I was curious to see if I could 3D print one of its main components—the hull. I quickly merged the scanned parts, transferred the result to Blender, and after alignment and solidifying, exported the model to OrcaSlicer. There, I scaled and positioned it for optimal 3D printing. At 50% scale, the print took around 8 hours to complete with supports.

©3DWithUs – Photo: Max Funkner

I couldn’t replicate the full-size hull in one piece due to the bed size 400 mm × 400 mm × 400 mm limitation of my Snapmaker Artisan, which otherwise did a great job. A large-format printer like the Elegoo OrangeStorm Giga, with its 800mm x 800mm x 1000mm build volume, would be able to handle it. As RC driving components, including batteries, getting smaller and more efficient, some RC model boats can now be fully replicated using budget FDM or Resin 3D printers. In some cases, assembling the boat by gluing printed parts together is a practical approach.

Update: From Broken to a New RC Boat

What started as a broken model boat ended up as a scanned, scaled, and 3D printed RC boat. Big thanks to Clive from SouthendMBC for putting it together and making it work on the water.

©3DWithUs – MP4: Max Funkner

Final Thoughts – A Hobby Full of Inspiration

This visit reminded me that technology and tradition don’t have to be at odds. RC boating is a perfect example of how hands-on creativity can coexist with modern tools, such as 3D printing.

There’s plenty for 3D printing enthusiasts to explore here – whether it’s designing boat parts, scanning and replicating models, or just getting out to enjoy a new kind of project.

If you have a similar club nearby, I highly recommend paying them a visit. You might leave with more than just inspiration – I certainly did.

©3DWithUs – Photo: Max Funkner

Sources & Links:

Big thanks to Jim Oughton, Secretary SMBC, for introducing me to the club members and providing helpful information.

If you’re thinking about dipping your toes into RC boating through 3D printing, here are some excellent examples online that blend visual appeal with printability. Below are a few standout models worth exploring.

RC Cape Class Patrol Boat

Patrol Jet Boat

Have questions? Feel free to ask in the comment section below.

For a wider discussion or to share your own RC Model Boat experience, join us in the forum: