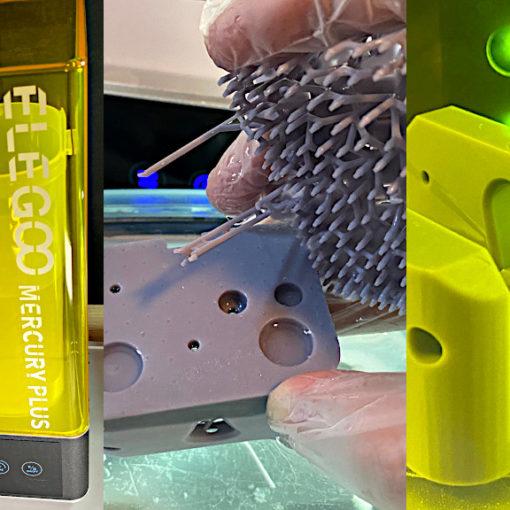

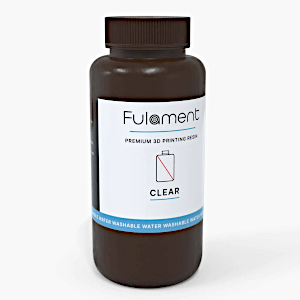

Resin 3D printing can be a messy process, and some users may not want to expose themselves to commonly-used solvents like IPA or acetone. Fulament Water Washable Clear Resin offers an alternative to standard resins by enabling users to rinse their models using water instead of a solvent like IPA before curing. This means that models can be simply soaked in a tub of water and gently agitated instead of requiring a separate rinsing machine.

Recommended Settings

Exposure Time LCD:

Base Layer: 60 seconds

Standard Layer: 8 seconds

Mono LCD:

Base Layer: 50 seconds

Standard Layer: 3 seconds

DLP:

Base Layer: 15 seconds

Standard Layer: 1-5 seconds

Water Washable Clear

Official Website

While their name might imply a specialization in filament-based 3D printing, I was impressed with the resin offered by Fulament and it’s clear that the company has put time into making the resin printing process more accessible to end-users by including settings and mechanical properties directly on their product page. The resin is easy to print and easy to process, but it’s not quite as clear as the name would imply. Prints tend to have a slight yellow tint, and can be cloudy after curing.

Resin Review

Straight out of the bottle, Fulament Water Washable Clear Resin has a slight yellow tint to it that becomes apparent when it fills the vat. Pouring it into a container better shows this tint, and you can see in the above picture that the resin is more translucent than clear.

(Photo: Andrew Sink)

Water Washable Resin can be processed without solvents like IPA in the rinse process, which makes it easier for users to clean and reduces exposure to potentially dangerous materials. In my experience, most water-washable resins are able to achieve a similar level of detail to standard photopolymer resins like Elegoo Standard (review). Models printed with Fulament resin have a high level of detail and are easily post-processed.

(Screenshot: PrusaSlicer)

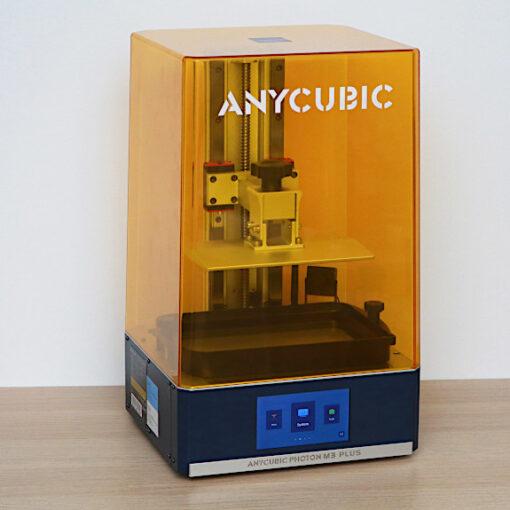

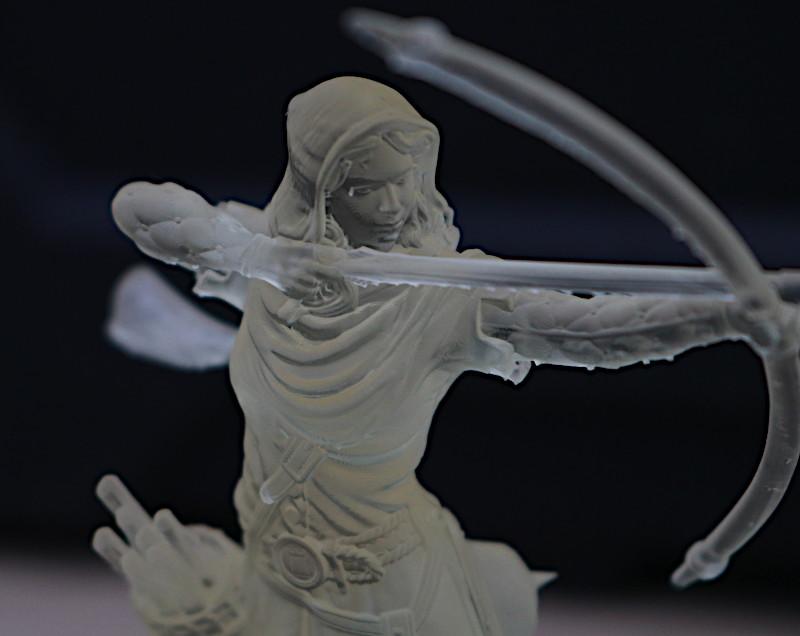

3D Printed on Prusa SL1S

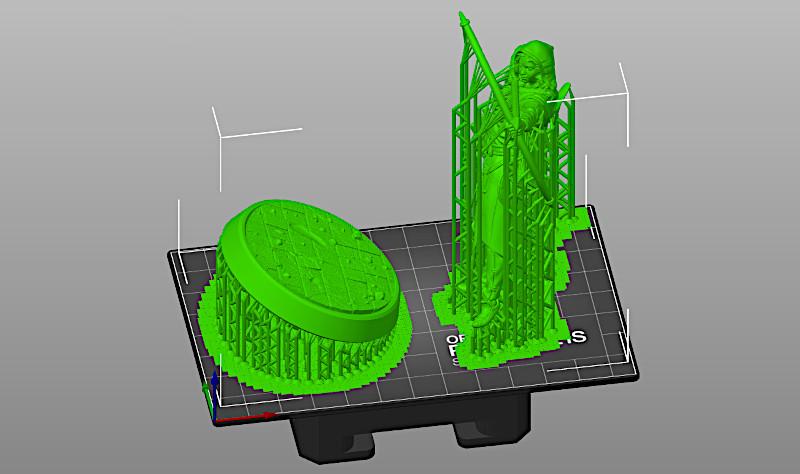

Fulament includes a QR code on the side of their bottles which links to the recommended settings for each resin. This guide made it easy for me to import the settings into PrusaSlicer for preparing the model to print on the Prusa SL1S (affiliate link). PrusaSlicer offers many of the same features (hollowing, support generation, etc.) as ChituBox, but it offers an optimized experience for the resin 3D printer. I used a pre-supported model from Loot Studios for this print, which is a 75mm miniature of an archer.

(Photo: Andrew Sink)

After printing, the model has a slight yellow tint that is visible before curing. The thin support structures are noticeably more clear than the model itself. This is due to the level of tint increasing as the model increases in thickness; thin structures are clear while thicker layers become more opaque.

(Photo: Andrew Sink)

The model displays excellent transparency when first removed from the printer, but much of the gloss is removed during the washing process. Since this is a water washable resin, I used a tub of warm water to rinse off the excess resin and make the support material easier to remove.

(Photo: Andrew Sink)

The detail on the model is visible and impressive, and even small features like the embossed pattern on the belt buckle and the hair on the archer look sharp. Fine details like wrinkles on the shirt and even stitches on the pants of the model are equally crisp, although the translucent nature of the material can make them hard to distinguish without a dark opaque background.

Increasing Transparency of Clear Resin

Printing clear (or transparent) models is an obvious application of clear resins, but the difficulty in post-processing can lead to a reduction in overall clarity. With Water Washable resin, models tend to look cloudy or matte after rinsing due to the slightly rough surface. To experiment with improving clarity, I allowed a 3D print to drip-dry overnight, and then placed it in a curing chamber without rinsing.

(Photo: Andrew Sink)

The model cured without rinsing showed a significant increase in clarity, at the expense of surface accuracy. Some of the fine detail in the model didn’t resolve, as the small nooks and crannies that would have been rinsed out were instead cured solid. While this process leads to a reduction in general accuracy, the clarity I was able to achieve without any post-processing is something I imagine many users would be interested in trying.

Wide-Neck Bottle

It is tricky to get any resin back into the bottle. If the resin contains cured bits, they block the filter and may push the bottle off-balance, tip it over, and create a mess. Fulament original bottles have wide necks to eliminate such risks.

(Image: Fulament)

Where to Buy Fulament Water Washable Clear Resin

Fulament offers resins in a variety of sizes and options. The bottles are available in both 500g and 1000g bottles, and Fulament has a unique “Subscribe & Save” which will automatically send resin to users on a 14, 30, 60, or 90 day schedule. For users operating a print farm or using Fulament resin as part of a business, this option is helpful to keep resin in stock.

To summarize my review, I was impressed with the quality of Fulament Water Washable Clear Resin, and the low cost combined with easy processing makes this a great resin for experimenting with translucent models. However, users looking for an optically clear resin for fully-transparent models may want to compare it to Siraya Tech Simple Clear resin, which offers a less-tinted model but requires a solvent-based wash before curing.

Read more: Siraya Tech Simple Clear Review

Using Siraya Tech Simple Clear resin, users of resin 3D printers are able to make models with a high level of translucency while minimizing the yellow tint associated with most clear resins. It’s worth taking a moment to discuss the differences between some common marketing terminology …

- More Clear Resins:

- Siraya Tech Simple Clear Resin (affiliate link)

- Anycubic Clear Resin (affiliate link)